UC9801A Hi-Pot and Insulation Tester for SMPS Transformer Testing

UC9801A series program control safety tester has AC withstand voltage test, DC withstand voltage test and insulation resistance test function.

A Hipot test is necessary to test the stress of an electronic device for safety and quality purposes.

Under high voltage it checks that there is no breakdown or perforation occurring, and that insulation distances on the line and in the air are respected.

Tests can be conducted between mutually insulated sections of a part or energized parts and electrical ground. In either case, during testing, electric current will flow between two points.

What Is Hi-Pot Testing

The Hi pot test is a test of the dielectric strength of the insulation to ground. It is used to determine if the ground wall can handle an over-voltage situation.

An over-voltage is a voltage higher than the peak operating (line to line) voltage of the device under test (DUT).

The term ‘Hipot’ is short for ‘high potential,’ that itself is short for the more technical term for Hipot testing, which is a ‘Dielectric Withstand Test.’

Hipot represents a class of electrical safety testing instruments.

The reason “good isolation” is widely used to describe Hipot testing is because it does just that—it’s used to verify that finished appliances, transformers, circuit boards, or electric motors have proper electrical insulation, and with regard to wire harnesses and custom cable assemblies, Hipot testing is used to verify the correct operation of safety circuits.

How is the Hi Voltage test performed?

Hipot testing is performed by applying a voltage between any two points intended to be electrically isolated, and measuring the resulting leakage current.

The hipot voltage may be applied between electrical circuits and chassis ground, for example, or between primary and secondary circuits isolated by a transformer.

Brief Introduction of UC9801A Hi-Pot Tester

A new generation ARM processors with resolution 480*272 LCD display, UC9801/02 series program control safety tester has AC withstand voltage test, DC withstand voltage test and insulation resistance test function.

It has arc detection function. Programmable testing is possible with three test modes. Optional RS485 interface, instrument networking can be realized easily by MODBUS communication protocol.

It determines the suitability of the dielectric or insulation barrier between hazardous and non-hazardous parts.

Hipot testing (dielectric strength testing) appears in nearly every product safety standard and is a fundamental test used to check a fully assembled product as it exits the production line.

UC9801A Hi-Pot and Insulation Tester for SMPS Transformer Testing

UC2869XB Automatic Coil Transformer Inductance Tester India

Working Video of the Hi Voltage Tester

Performance Characteristics

- A new generation ARM processors with resolution 480*272 LCD display

- List display function, multi-step results one screen display

- Keyboard lock function, automatically save test conditions when shut down

- Voltage rise time is short (The fastest less than 0.2S)

- Open and short circuit detection function(OSC)

- Body protection against electric shock

- Discharge automatically and quickly after testing

- Current base reset function

- Support U disk and internal file storage

- RS232 and handler interface configuration, which is suitable for configuring automatic test system

Technical Specifications

| Model | UC9801C |

| Measurement Parameter | ACV/DCV/IR |

| Voltage Output Range (AC) | 50V~5kV accuracy±2% |

| Voltage Output Range (DC) | 50V~6kV accuracy±2% |

| Leakage Current (AC) | 0.001mA~12mA accuracy±2% |

| Leakage Current (DC) | 0,001mA~5mA accuracy±2% |

| Voltage Rise Time | 0.1~999.9 sec. |

| Test Time Setting | 0.1~999.9 sec. |

| Arc Detection | 1~9 grade |

| Insulation Resistance (IR) | Test Voltage : 50V~1kV DC Measurement Range : 100KΩ~50GΩ |

| Memory group of setting up condition | 100 groups |

| Comparator | Set the upper and lower limits, unqualified sound and light alarm |

| Trigger modes | Internal trigger, external trigger (optional) |

| Interface | RS232C, handler |

| Power requirements | Voltage : 198VAC~240VAC frequency : 50Hz Power : Maximum 100VA |

| Accessories | High voltage test probe |

| Optional accessories | Pedal start switch |

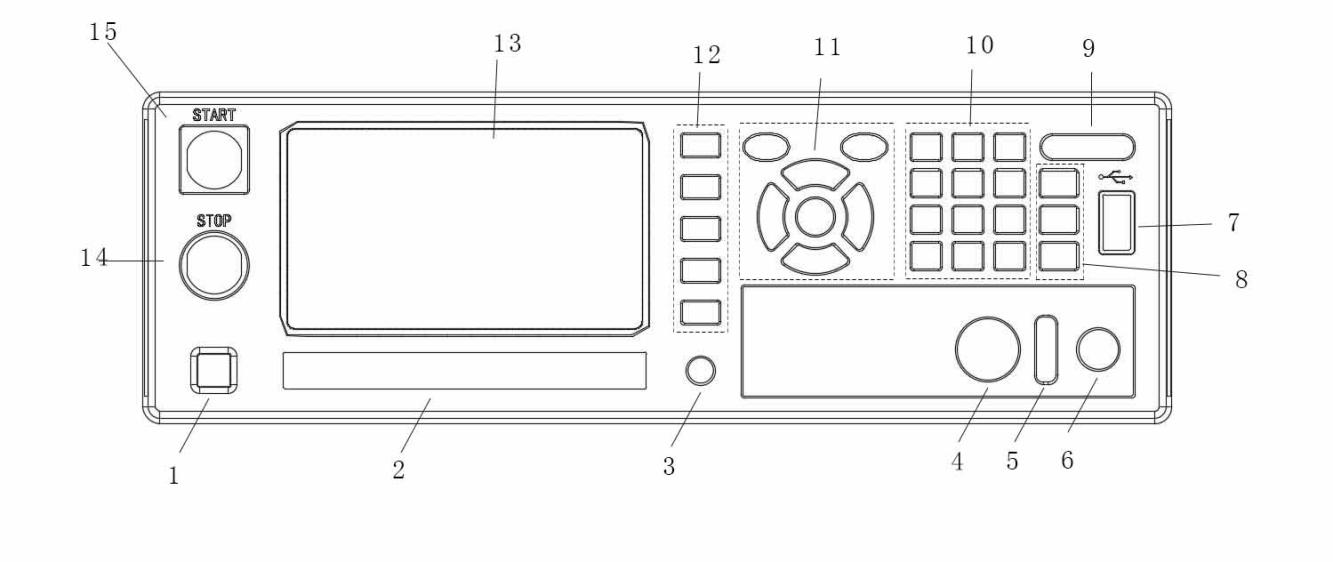

Overview of instrument panel

Front panel description

| No. | Name | Description |

| 1 | Power switch | Switch on and off the power of the instrument. The indented position is on and the pop-up position is off. |

| 2 | Trademarks and models | Type label |

| 3 | File key | Open the file management page and switch internal and external storage pages |

| 4 | High end of output voltage | high end of test voltage output |

| 5 | High voltage output lamp | Whenever there is a potential voltage output, it will flash, indicating that the test is in progress. |

| 6 | Low end of output voltage | low end of test voltage output |

| 7 | USB HOST interface | Used to connect USB flash drive (U disk). Support FAT16 and FAT32 file systems. Support firmware update, record test data, store screen images, store and call test parameters files, etc |

| 8 | function keys | ESC to cancel button Please delete key ENTER confirm |

| 9 | indicator light | PASS, FAIL indicator light |

| 10 | enter key | A full-featured numeric/character keyboard for entering data or characters when required for comment information such as file names. |

| 11 | Main menu The direction key |

MEAS: measurement result display page and selection. SETUP: test condition Settings page and selection. Arrow keys are used to move fields, which are currently set to display as an inverted color image. |

| 12 | soft function key | These five keys have different functions in different menus, and the corresponding functions are displayed in the menu area on the right side of the display screen. |

| 13 | LCD Screen | Displays all information provided by the instrument. |

| 14 | STOP key | To stop testing; It can also be used to cancel prompt states such as PASS, FAIL, etc |

| 15 | START key | Used to start the test, and once the test is started, the DENGER light flashes. |

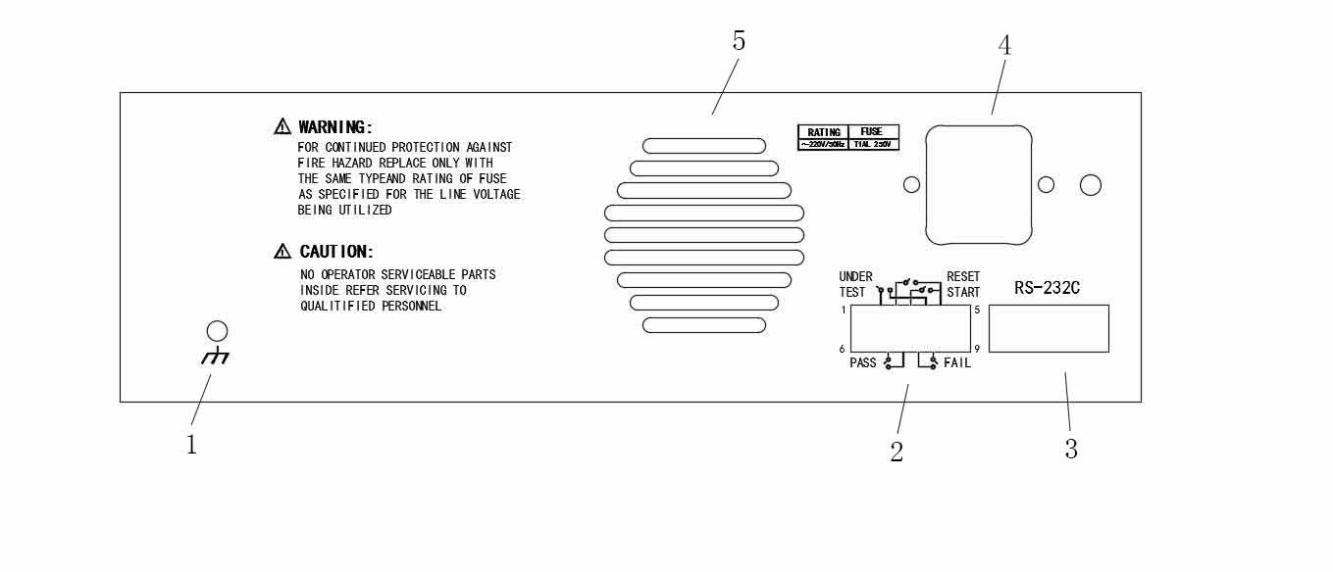

Rear panel description

| No. | Name | Description |

| 1 | Protective terminal | Used to connect instruments to the earth. Note: do not use this instrument without connecting the earth, otherwise it may not work properly and may be electrocuted. |

| 2 | HANDLER interface | It is more convenient to connect with 9 – core D socket than PLC interface. Suitable for multi – instrument universal control circuit connection. TEST: synchronous control signal output by the machine when the instrument starts high-voltage output. START: input the START signal of the machine to START the high-voltage output, which is equivalent to the START key of the front panel. RESET: input the RESET signal of the machine to STOP the high-voltage output, which is equivalent to the STOP key of the front panel. PASS: the qualified signal output by the machine, equivalent to the PASS indication on the front panel. FAIL: the unqualified signal of the machine output, equivalent to the FAIL indicator of the front panel. |

| 3 | RS232C serial port | Serial communication interface to achieve communication with computer. |

| 4 | Three-wire socket | Used to connect ac power supply, embedded fuse holder. |

| 5 | air fan | Power amplifier circuit heat sink, pay attention to the preservation of air circulation space. |

Battery Internal Resistance Tester Distributor India

Inductance measurement of Transformer, Relay, Solenoid Coils with LCR Meter

Features:

■ Four Test functions — ac withstand voltage test, dc withstand voltage test, insulation resistance test, open short circuit test

When connected to the load, the multi-parameter test can be carried out continuously by editing the test scheme.

■ AC withstand voltage test 5kV/12mA

The high-voltage module of this instrument is a class AB power amplifier circuit and a 100VA high-voltage transformer, achieving the output of 5kV/12mA (maximum 1 minute), and the distortion degree of waveform is less than 3%.

Since the instrument has a maximum upper limit current of 12mA and a minimum voltage of 50V, the instrument generates a test voltage consistent with 50Hz/60Hz, an independent power supply, and the automatic voltage adjustment rate is less than ±(1%+10V). When the test voltage is set, there is no need to adjust the output voltage.

■ DC withstand test 6kV/5mA

The 8801 series can provide dc withstand voltage testing with a wide voltage range (maximum output dc 6kV). Automatic voltage adjustment of 600Hz frequency hardware, voltage load adjustment rate ≤1%+10V.

S insulation resistance testing 0.050 kV to 1.000 kV (resolution) of 1 v / 0.1 M Ω Ω to 10.0 G, the maximum rated current for 5 ma.

Insulation resistance test range:

When the voltage is less than 500 v: 0.1 M Ω ~ 1 g Ω precision of + / 10% reading plus five words

When the voltage is greater than 500 v: 0.1 M Ω Ω range accuracy of ~ 1 g + + five words reading (5%), 1 g Ω ~ 10 g Ω range accuracy of plus or minus 10% (reading + 5 words), 10 g Ω ~ 50 g Ω range accuracy of plus or minus 15% (reading + 5 words).

■ Open short circuit detection: determine whether the connection of the tested part is reliable before starting the high voltage to ensure the accuracy and safety of the high voltage test.

■ Fully Programmable rs-485 interface (optional) and rs-232c interface as the standard

In addition to power conversion and other functions, other can be remote control. Test conditions such as dc voltage withstand test, ac voltage withstand test and insulation resistance test can be remotely controlled. Test results can also be read from behind by remote control. The GPIB and rs-232c interfaces provide a consistent standard test interface for PCS and other devices.

■ Easy connection to control HANDLER interface

HANDLER interface, which can input START and STOP signals and output TEST, PASS and FAIL signals. It can be conveniently connected with foot switch into foot control, connected with simple test fixture to realize safety interlock, pneumatic control, test indication and so on.

■USB port for backup

USB interface can save the test plan written by the instrument and customer measurement files to the external USB disk, or transfer the instrument from the USB disk to facilitate the setting and use of batch instrument.

■ Test waiting time setting

You can set the test waiting time from 0.1s to 99.9s with a resolution of 0.1s. During this time, the instrument will output TEST control signal to control external equipment to ensure reliable TEST connection, and then start the high-voltage TEST process.

■ Rise time control function

In ac withstand test, dc withstand test and insulation resistance test, the test voltage can slowly rise to the set value, instead of providing the set voltage to the test piece immediately after starting the test. Voltage rise time 0.1s to 999.9s resolution 0.1s.

The 8801 series conforms to UL test standards and IEC withstand test standards (the initial voltage is less than half of the test voltage and the rise time can be specified upon reaching the set test voltage).

■ Drop time control function

In the ac withstand voltage test, the test voltage energy decreases gradually. The voltage drop time can be set to a resolution of 0.1s from 0.1s to 999.9s.

■ Discharge function

Normally, the measured part is capacitive. At the moment when the dc withstand voltage test and insulation resistance test are cut off, the test piece remains fully charged, so there is a risk of electric shock.

This series has the function of forced quick discharge to the tested part after the dc withstand voltage test and insulation resistance test.

■ High test accuracy

8801 series voltage digital display, the voltage precision is ± (1% reading +5V) in withstand voltage test, and ± (1% reading +2V) in insulation resistance test. The accuracy of the with-stand current test is ± (1% reading +5 words).

■ Current clearing function

Ac and dc withstand voltage tests require high sensitivity and high voltage, and the current flowing through the stray capacitance of the test line and fixture can make the test inaccurate. This series has current clearing function to offset current offset.

■ Ease of operation

This series is easy to operate, with arrow keys and numeric keys to ensure users don’t have trouble getting started.

■100 test plans, each can have 100 test items, a total of 10,000 test items can be saved

Can edit 100 test files for various test portfolios required by customers; Each test program can have up to 100 test items.

The test items are any one of ac withstand voltage test, dc withstand voltage test, insulation resistance test and open circuit short circuit determination. The test conditions of each item are unrelated.

The instrument’s memory can store 10,000 test items, and when there are many storage items, unused data can be transferred to external storage (the machine supports external usb drive to store data).

Warning: the instrument USES high voltage of 5kV AC/DC. Therefore, do not touch the test piece or test wire, which may lead to electric shock.

Safety measures such as fences shall be provided around the tested object to ensure user safety. In addition, to ensure safety,

Extreme care is taken to prevent high output pressure due to improper connections and operations.

UC9801A Hi-Pot and Insulation Tester for SMPS Transformer Testing

4 Spindle Transformer Coil Winding Machine India

Overview of instrument performance

8801 can provide 5kVAC/12mA withstand voltage, 6kVDC/5mA withstand voltage, insulation resistance high voltage test.

High voltage module is a class AB power amplifier to ensure the programmable output voltage, eliminating the trouble of manually adjusting the voltage for each test.

In addition, the isolation of output high voltage power supply and line power supply is ensured.

The voltage feedback loop used for ac and dc voltage withstand is used to ensure the accuracy of the output voltage, so that the actual voltage adjustment rate is much lower than the voltage adjustment rate of the transformer, which can be used to measure the products whose VA requirements are much higher than the actual power of this instrument.

In the insulation resistance test, since the load impedance is usually very high, the charging current up to 5mA is guaranteed by the same dc voltage withstand power circuit, but the voltage feedback compensation is not carried out.

It can be set to work at 50 hz or 60Hz when ac output, no longer limited by line voltage; Meanwhile, the voltage waveform is not affected by the line voltage. At the same time, the instrument also tests the real part of the current (pure resistance current), which can avoid the large current generated by distributed capacitance affecting the user’s judgment of the actual insulation resistance

To solve the problem of large ripple of power supply for DC and insulation resistance test, the 8801 test instrument generates 600Hz ac power supply and forms DC voltage as power supply after rectification, which ensures that the ripple of DC power supply is far smaller than that of the old voltage regulator and can guarantee the stability of 5.000kv and 5mA test.

Once connected with the load, this series can not only independently carry out ac withstand voltage test, dc withstand voltage test, insulation resistance test, but also carry out multi-item test through the project setting of the test scheme.

8801 series is equipped with industrial control HANDLER, GPIB (optional), RS-232c for computer connection, USB for data backup, which enables the instrument to adapt to various automatic test systems with high security and reliability.

Basic operation

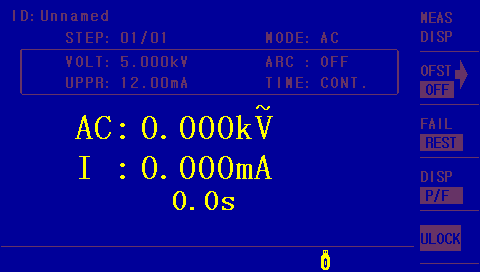

Measurement display page

Press the (MEAS) menu key to enter the measurement display page. The measurement display page is as follows (take AC as an example) :

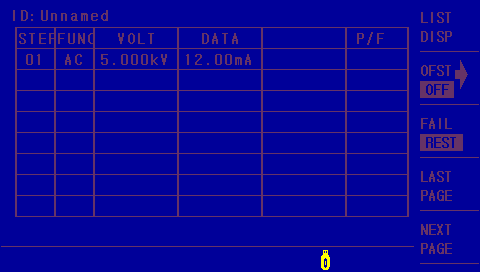

List display page

Press the menu key of MEAS and the soft key of “list display” to enter the list display page. The page is as follows

Measurement Settings page

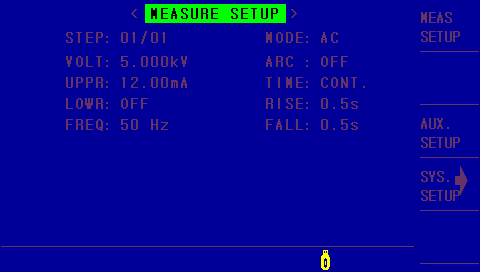

Press the SETUP menu key to enter the measurement Settings page. The measurement Settings page is as follows:

Auxiliary Settings page

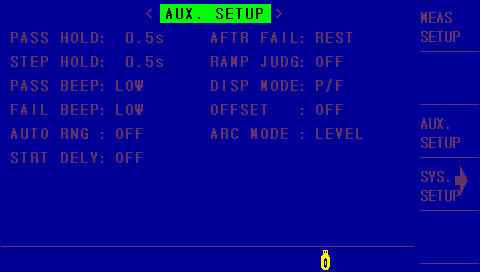

The auxiliary setting interface is to set some Settings unrelated to specific test project parameters but related to the test scheme of the instrument.

Press SETUP menu key, and then press “auxiliary Settings” soft key to enter the auxiliary Settings page. The auxiliary Settings page is as follows:

Test Result Processing

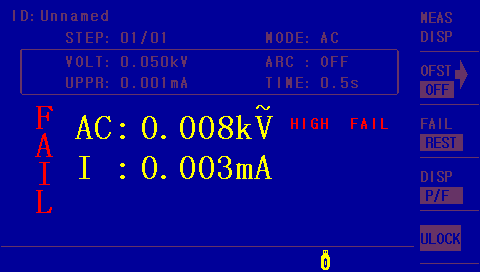

If there is no over-limit on the right side of the figure in the above process, the instrument will judge that the tested part meets the set requirements, display the PASS, and light up the qualified indicator (the qualified judgment processing mode is controlled by the “qualified maintenance” under the “measurement configuration” page).

Otherwise, the instrument will display FAIL and category (see HIGH FAIL as an example in the figure below), and the failure indicator will be on (the unqualified judgment processing mode is controlled by the “failure mode” under the “measurement configuration” page).

When the results are printed, multiple test items are automatically moved to the next test item, otherwise the test wait state is returned.

UC9801A Hi-Pot and Insulation Tester for SMPS Transformer Testing

12 Spindle Automatic Transformer Coil Winding Machine

Other Services we offered in Testing and Measuring in India:

Electronic Component Test

Used for test various types of electronic components

• Resistance Test

• Capacitance Test

• Inductance

Coil and Winding Product Test

Used for network transformer test, power transformer test, filter test, etc

• Transformer Tester

• Impulse Winding Tester

• DC Resistance Tester

• Filter Balance Tester

Wire Harness Test System

- New energy vehicle wire harness test

- Automobile, Train, Aerospace, Ship wire harness test

- Home appliances, Smart phone wire harness test

- Medical equipment wire harness test

- Other industry high voltage wire harness test

About Us

We are a high-tech enterprise engaged in sales and service of test instruments. At present, the company’s main products are: LCR meter, Hi-pot tester, automatic transformer tester, DC low resistance tester, impulse winding tester, wire harness test system.

After years of customer accumulation and product market recognition, we have become an influential brand in the industry.

“Quality first, customer satisfaction” is always our first goal. Quality is the life of an enterprise.

For this reason, we strive for excellence, optimize the design, improve the performance of products, and focus on the details of each product.

At the same time, we are also actively expanding overseas business. We gradually integrate the technology and experience accumulated for many years into the international competition system, to create a marketing system in Asia and European countries.

More details, please contact freely :

DEPTRONICS TECHNOLOGIES

Contact : Deepanshu Saxena

Mobile : +91-8800622761

WhatsApp : https://wa.me/918800622761

Email : [email protected]