We bring an advanced range of Taping machines used for wrapping on Charger cabinets, mobile charger plastic body, mobile charger Housing etc for the customers in various designs and sizes.

This machine is frequently used in charger manufacturing industries to wrap or tape Polyolefin shrink wrap or tape on plastic body of mobile chargers.

There are huge market of mobile chargers from local to top brands in India and all manufacturers wants to improve the packaging quality of chargers to avoid any scratch on body or plastic cover.

To solve this type of problems, we introduce a new standard machine specially designed for cabinet tape wrapping to protect it from any kind of scratches.

These machines can be customized as per the client requirements and work standard.

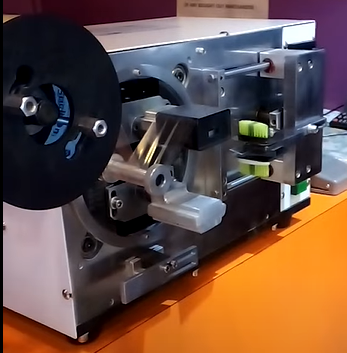

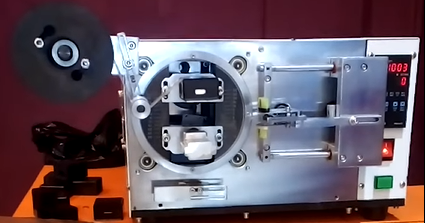

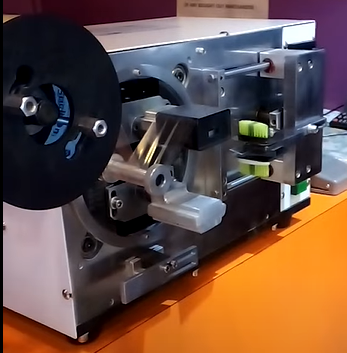

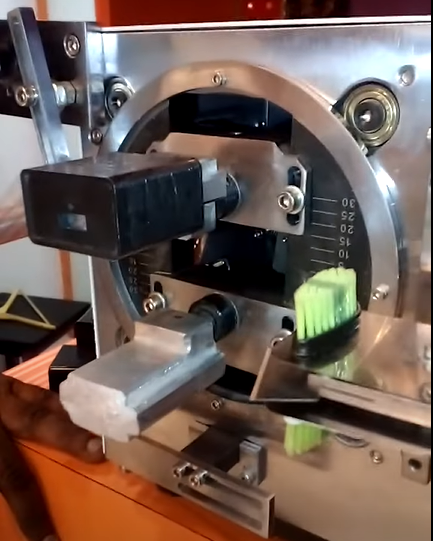

You can find some of the pictures and videos below to get more clarity.

Mobile charger cabinet or housing taping machine

Machine operating Video

Gallery

Which type of Tapes are used to wrap charger plastic cabinet or Housing

- Polyolefin Shrink wrap

- Transparent Stretch wrap

- Transparent Polyester tape

- Transparent PVC tape

Machine Specifications

| Features | Automatic taping with cabinet change-over. Tape cutter with start and finish wiper and automatic unload. 2 handed start button operation. Number of turns of tape is programmable from 1 to 9 turns. |

| Cycle Time | Typically 3 seconds per bobbin or cabinet for 2 turns of tape, cut and auto unload. |

| Application | Taping of Mobile charger cabinet, plastic body or housing |

| Production | Min. 1500 pcs, Max. 2200 pcs per hour |

| Supply reel dia | 76mm I.D. standard – other sizes available |

| Changeable Parts | Tape roller attachment, Jig tooling, cutter and wiper fixture, safety cover, tape backing removal feature |

| Power | AC 230 / 110 V ± 10%, 50 – 60hz |

| Dimensions | 600 L * 650 W * 300 H (mm) |

| Net weight | 35 kg |

Machine Working

1. Manual insert cabinet

2. Automatic tape on cabinet

3. Automatic cut tape

4. Manual unload products

Instructions for use

1. Please use 110v ,220V ± 10% / 50HZ power supply.

2. Do not place the device in a strong electromagnetic interference environment.

3. Equipment should be -10 ℃ -40 ℃ 95% RH non-condensing environment use.

4. Main circuit board is susceptible to electrostatic damage and damage, do not touch the main circuit board.

5. Do not start and shut down the power frequently, turn off the power after 10 seconds before starting.

We are Manufacturer

Our goal, a company dedicated to the design, manufacture and distribution of for cabinet or housing protection systems, is to be recognized as a specialist in our sector, with a reputation for high-quality and innovative products and services, respecting the environment and ensuring the efficiency and sustainability of our activities.

We provide all kinds of service & support in all over India by engineer’s visit, support on audio or video call, spare parts supply, AMC proposal etc.

We have a perfect quality assurance and after-sales service system to ensure the good reputation of our all machines.

As one of the leading taping machine manufacturers and suppliers in India, we warmly welcome you to buy cheap taping machines made in India here from our factory. All customized products are with high quality and competitive price.

Mobile charger Cabinet raping Macine Recurment

I need this product