As power electronics continue to evolve, SMPS (Switched Mode Power Supply) transformers have become more compact, efficient, and performance-critical than ever before. Modern applications demand transformers that meet tight electrical tolerances, high insulation reliability, and consistent quality across large production volumes.

Traditional manual or semi-automatic manufacturing methods struggle to keep pace with these expectations. Variations in winding accuracy, insulation placement, soldering quality, and testing reliability often lead to rejections, field failures, and rising labor dependency.

To overcome these challenges, manufacturers worldwide are shifting toward fully automatic SMPS transformer production lines—integrated systems that connect winding, soldering, core assembly, taping, and testing into one continuous, synchronized workflow.

Why the Industry Is Moving Toward Fully Automatic Production Lines

1. Rising Demand for Consistent Product Quality

Modern SMPS transformers must meet strict electrical and insulation standards. Manual and semi-automatic processes often introduce variations in winding accuracy, insulation placement, and soldering quality. Fully automatic production lines eliminate these inconsistencies by digitally controlling every critical parameter, ensuring uniform quality across large production volumes.

2. Shortage of Skilled and Reliable Manpower

Transformer manufacturing heavily depends on skilled operators, especially for winding and insulation processes. However, retaining trained manpower has become increasingly difficult. Automation reduces dependence on individual skill levels and converts production into a process-driven system that delivers stable results regardless of operator experience.

3. Need for Higher and Predictable Production Output

As market demand increases, manufacturers require stable cycle times and predictable daily output. Fully automatic production lines operate continuously with minimal downtime, allowing manufacturers to meet delivery commitments without increasing manpower or shift complexity.

4. Reduction in Rejection, Rework, and Warranty Costs

Human-dependent processes often lead to hidden defects that appear during testing or in the field. Automated lines integrate inline testing and controlled assembly processes, helping detect issues early and significantly reducing rejection rates, rework effort, and post-sales warranty risks.

5. Improved Process Control and Traceability

Fully automatic systems use PLC-based control and recipe management, enabling manufacturers to store, repeat, and monitor exact process parameters. This traceability is especially important for OEM suppliers and export-oriented manufacturers who must maintain documented quality control.

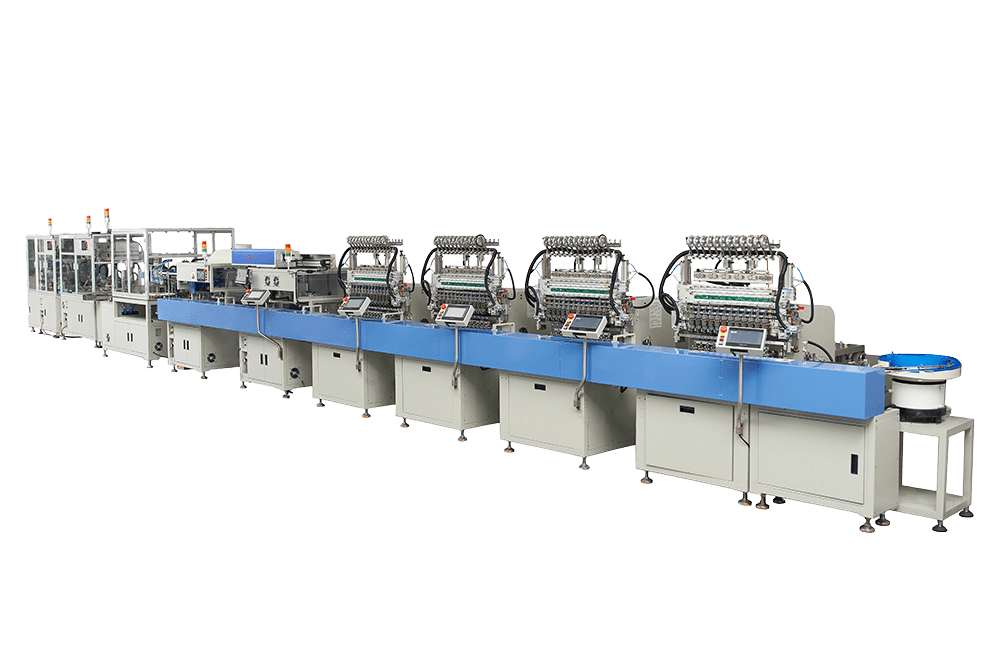

Overview of a Fully Automatic SMPS Transformer Production Line

A fully automatic production line is not a single machine—it is a carefully engineered combination of multiple specialized machines, digitally synchronized to work as one intelligent system.

The goal is simple but powerful:

👉 Raw bobbins enter at one end, fully tested transformers exit at the other—without manual handling between processes.

Each station performs a specific task with precision, repeatability, and speed, ensuring that every transformer produced matches the same quality benchmark.

Manufacturing Unit Running Video

Step-by-Step Manufacturing Flow

1. Automatic Bobbin Feeding System

The process begins with automated bobbin feeding units that orient and supply transformer bobbins from bulk storage. These systems eliminate manual loading errors and ensure correct positioning before winding.

Key benefits:

- Continuous supply without operator fatigue

- Consistent bobbin orientation

- Reduced handling damage

2. Automatic Bobbin Loading into Winding Stations

Robotic or servo-controlled loading mechanisms transfer bobbins directly into the winding machines. Each bobbin is accurately placed and clamped, ready for precise winding operations.

This stage ensures:

- Zero misalignment during winding

- High repeatability across batches

- Seamless integration with multi-station lines

3. Sequential Multi-Winding Stations with Insulation Taping

SMPS transformers often require multiple windings—primary, secondary, auxiliary, and feedback windings. In a fully automatic line, each winding is performed at a dedicated station, arranged sequentially.

At each station:

- Copper wire is wound with servo-controlled tension

- Turn count is digitally controlled

- Insulation tape or sleeves are automatically applied between layers

This approach guarantees:

- Uniform layer insulation

- Stable electrical characteristics

- No dependency on operator skill

4. Automatic Transfer to Soldering Section

After all windings are completed, the transformer is automatically transferred to the soldering area using conveyors or robotic handling. No manual intervention is required, maintaining process consistency.

5. Flux Dipping and Solder Dipping Process

In the soldering station:

- Terminals are first dipped into flux for proper wetting

- Controlled solder dipping ensures strong, clean joints

This automated process delivers:

- Consistent solder depth

- Reduced cold joints

- Improved long-term reliability

6. Automatic Core Feeding and Core Assembly

Ferrite cores are automatically fed, oriented, and assembled onto the wound bobbin. Precision alignment is critical here, especially for high-frequency SMPS transformers.

Automated core assembly ensures:

- Correct air gap control

- Stable inductance values

- Reduced mechanical stress

7. Optional Glue Dispensing System

For applications requiring enhanced mechanical strength or vibration resistance, an optional glue dispensing unit applies adhesive with precise volume control.

This is particularly useful for:

- Automotive power supplies

- Industrial SMPS units

- Export-grade products

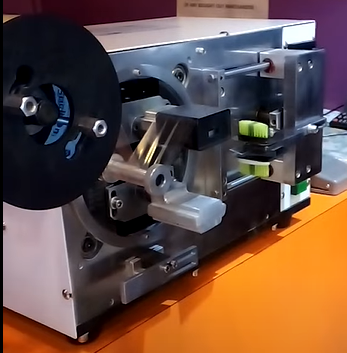

8. Automatic Core Taping

After assembly, the core is securely taped using automated taping machines. Tape tension, overlap, and positioning are digitally controlled to ensure uniformity.

Benefits include:

- Improved insulation safety

- Professional appearance

- Consistent mechanical locking

9. Inline Electrical Testing

Each transformer then passes through inline testing stations that verify critical electrical parameters such as:

- Inductance

- Leakage inductance

- Turns ratio

- DCR

- Polarity

Test results can be logged automatically for quality tracking and traceability.

10. Optional Hi-Pot and CCD Inspection

For manufacturers targeting high-reliability or export markets:

- Hi-pot testing ensures insulation withstand strength

- CCD vision systems inspect physical defects and assembly accuracy

These options further enhance product credibility and compliance.

11. Automatic Unloading into Trays

Finally, fully tested transformers are automatically unloaded into trays or bins, ready for packing or downstream processes—without manual contact.

Key Technical Features of the Production Line

A fully automatic SMPS transformer production line stands out due to its advanced engineering and digital control capabilities:

- Fully synchronized multi-machine architecture

- Servo-driven winding for precise turns and stable tension

- Automated insulation tape cutting and placement

- Continuous flow with zero manual handling

- Centralized PLC + HMI control system

- Recipe-based parameter management for different transformer models

- Inline testing with optional data storage and reporting

- Modular construction allowing future upgrades

Supported Ferrite Core Types and Transformer Designs

The production line can be configured to handle a wide variety of ferrite cores, including:

- EE / EER series transformers

- EFD cores for compact SMPS designs

- ETD cores for medium to high-power applications

- PQ cores for high-efficiency power supplies

- RM cores for precision electronics

Additionally, the line supports:

- Single and multiple secondary windings

- Auxiliary and feedback windings

- Multiple wire diameters and insulation methods

- Custom pin configurations and termination styles

This adaptability allows manufacturers to produce both standard and customized transformers on the same platform.

Industries That Benefit Most from This Automation

A fully automatic SMPS transformer production line is ideal for manufacturers involved in:

- SMPS power supply manufacturing

- Mobile chargers and adapters

- LED driver production

- Solar inverter and UPS systems

- EV charging modules

- Industrial automation and control panels

Companies focused on high volume, consistent quality, and export standards gain the strongest competitive advantage.

Key Advantages of Full Automation

Adopting a fully automatic production line delivers measurable benefits:

- Stable and predictable production output

- Uniform electrical and mechanical quality

- Major reduction in manpower dependency

- Lower rejection, rework, and warranty claims

- Cleaner and safer working environment

- Easy scalability as demand increases

Automation transforms production from skill-dependent to process-driven—strengthening both efficiency and brand reputation.

Production Capacity and Scalability

Actual output depends on transformer design and testing requirements. However, in practical industrial conditions, such a line can achieve:

- Continuous multi-shift operation

- Stable cycle times

- High hourly, daily, and monthly output

The modular design allows manufacturers to expand capacity by adding:

- Extra winding stations

- Additional testing modules

- Automated packaging or labeling systems

ROI and Payback – A Practical View

Return on investment is one of the strongest reasons manufacturers adopt full automation.

With a production capability of approximately 1500–1600 transformers per hour, the gains are immediate.

Key contributors to ROI include:

- Reduced labor costs

- Higher production per shift

- Lower rejection and service costs

- Improved consistency enabling premium customers

Once production volumes stabilize, many manufacturers achieve payback within a reasonable timeframe, making the investment strategically and financially sound.

How to Choose the Right Automation Partner

When investing in a fully automatic production line, choosing the right partner is as important as the machine itself. Look for:

- Proven experience in transformer automation

- Transparent technical discussions

- Strong after-sales and service commitment

- Availability of spares and upgrades

- Long-term partnership mindset

Why Choose Deptronics Technologies

Deptronics Technologies specializes in delivering complete, application-specific automation solutions for transformer and coil manufacturing.

With deep process understanding, practical field experience, and strong technical collaboration with global machine manufacturers, Deptronics focuses on reliable performance, not just machine supply.

Installation, Training, and After-Sales Support

A production line is only successful when it performs reliably on the shop floor.

Deptronics provides:

- Structured installation and commissioning support

- Operator and maintenance training

- Process optimization guidance

- Responsive after-sales and spare support

Frequently Asked Questions (FAQs)

Q1. Can multiple transformer models be run on one line?

Yes, through recipe-based changeover, depending on design compatibility.

Q2. Is the line expandable in the future?

Yes, modular architecture allows phased expansion.

Q3. What level of operator skill is required?

Basic training is sufficient due to PLC-controlled automation.

Final Thoughts

A fully automatic SMPS transformer production line is no longer a luxury—it is a strategic necessity for manufacturers aiming for quality, scale, and long-term competitiveness. By integrating winding, soldering, assembly, taping, and testing into a unified system, manufacturers gain control, consistency, and confidence in every transformer produced.

Contact Us

To discuss your transformer design, production targets, or automation requirements, contact Deptronics Technologies for a detailed consultation and solution proposal.

DEPTRONICS TECHNOLOGIES

📌 Contact Person: Deepanshu Saxena

📞 WhatsApp/ Mobile: +91-8800622761

🌐 Website: https://coilwinder.in/

📧 Email: [email protected]

For mass production of relay coils, check our “Automatic Production Line for Mass Manufacturing of Relay Coils”