What is the SQ Ferrite Core Flat Wire Automatic Production Line?

The SQ Core Flat Wire Line is a fully automated machine line engineered to handle flat copper wire winding and processing on SQ-type ferrite cores. Unlike traditional round-wire winding methods, flat wire winding offers:

- Better space utilization on the bobbin/core

- Reduced copper losses

- Higher current-carrying capability

- Superior electrical performance for high-frequency applications

This machine line ensures that every step—core loading, winding, soldering, and testing—is carried out automatically, delivering high productivity with minimal operator involvement.

Working Video :

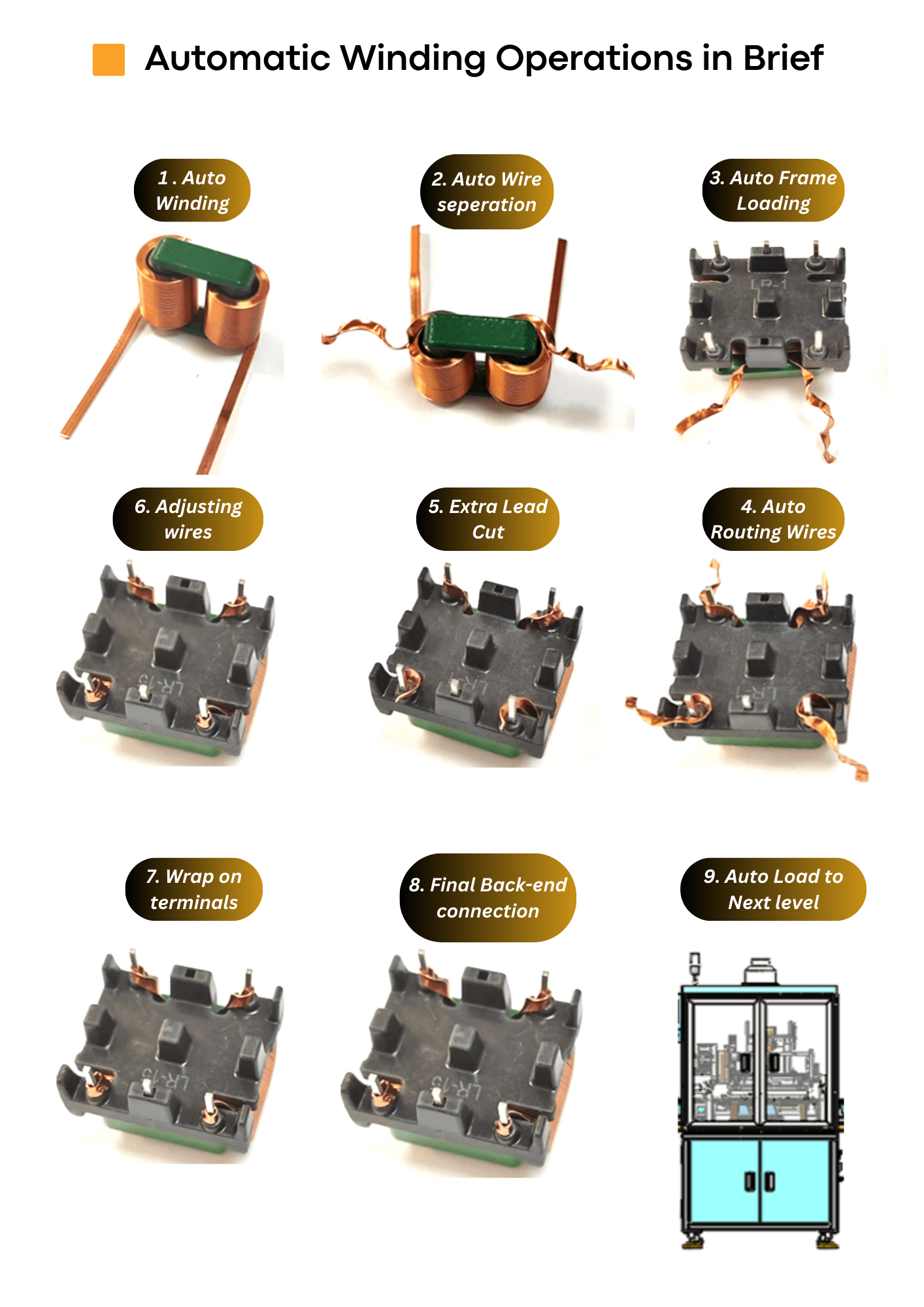

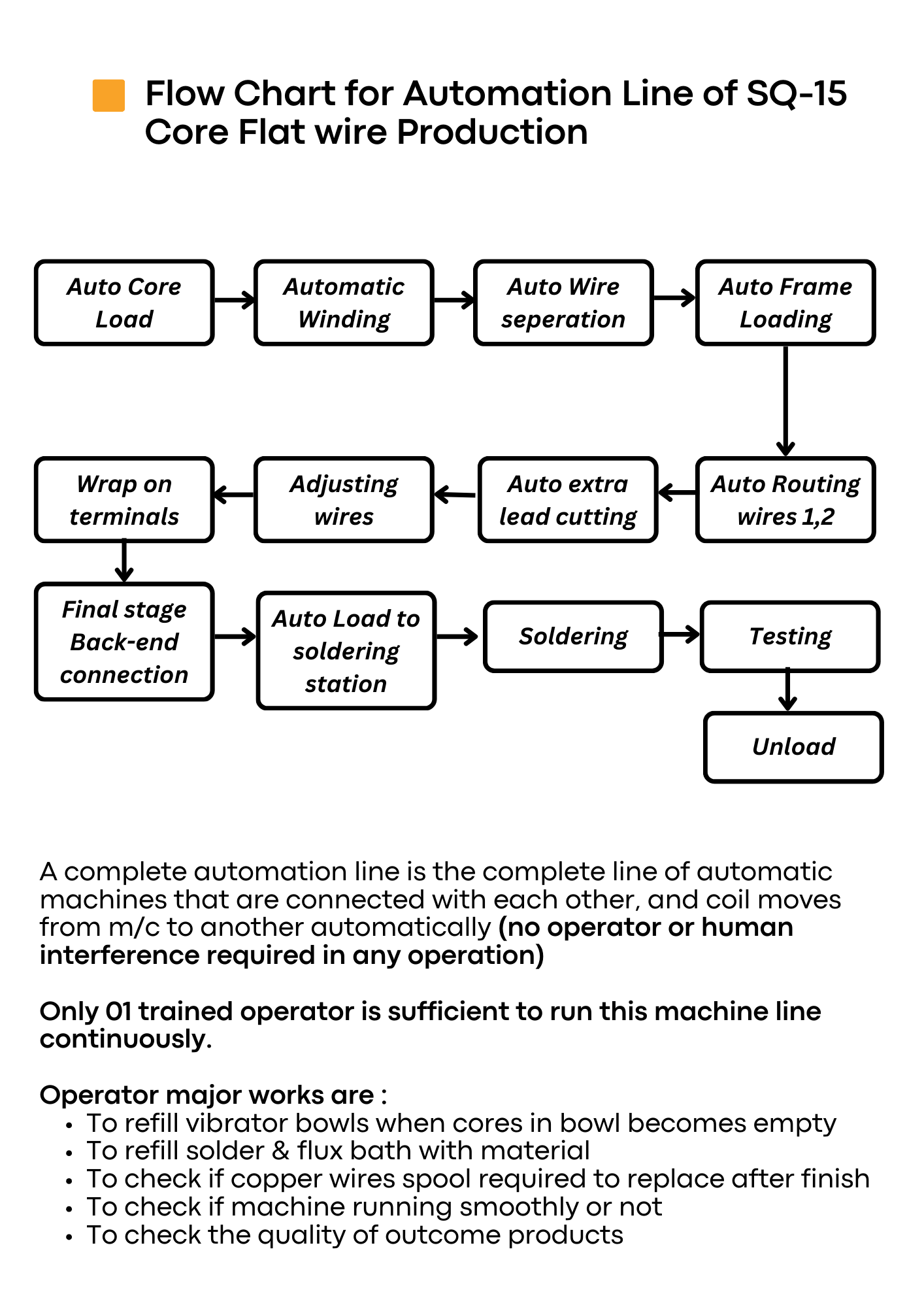

Production Workflow: Step-by-Step Machine Operations

One of the strongest selling points of the SQ Ferrite Core Flat Wire Automatic Production Line is its seamless workflow. Every operation is automated, eliminating human touch from start to finish. Let us examine each stage in detail:

1. Auto Core Loading

- The production line begins with automatic ferrite core loading.

- SQ ferrite cores are placed into a vibrator bowl feeder.

- The machine automatically aligns, orients, and transfers each core into the winding station.

- This process ensures that cores are uniformly fed, avoiding jams or misalignments that could slow down production.

Benefit: Eliminates manual core handling, increases speed, and ensures consistency.

2. Automatic Flat Wire Winding

- Once the core is loaded, the automatic winding station starts operation.

- Flat copper wire is precisely wound around the SQ ferrite core.

- Advanced servo motors and tension control systems guarantee perfect winding layers.

- The system is programmable, so different winding parameters (turns, direction, wire width) can be pre-set.

Benefit: Accuracy in winding directly impacts transformer performance. The automated line ensures zero deviation.

3. Wire Separation & Auto Frame Loading

- After winding, the wire ends (leads) need to be separated.

- The system automatically identifies and separates each lead.

- Simultaneously, a frame or fixture positions the core for the next step.

Benefit: Saves operator effort and prepares coils for lead routing.

4. Wire Routing, Lead Cutting & Adjusting

- Wires are automatically routed into correct positions.

- Extra leads are cut to exact dimensions

- Machine adjusts wire positioning to prepare for terminal connection.

5. Terminal Wrapping & Final Back-End Connection

- Wires are wrapped around designated terminals.

- Machine ensures proper tightening for secure electrical connection.

6. Auto Soldering & Flux Dipping

- A robotic arm transfers the coil to the flux bath.

- Leads are coated with flux, which improves solder bonding.

- Immediately after, the coil is dipped into the solder bath.

- Controlled temperature ensures a perfect solder joint every time.

Benefit: Produces clean, reliable soldering with zero cold joints or weak connections.

7. In-Line Quality Testing

Every coil passes through automated testing stations:

- High-Voltage Test: Checks dielectric strength (optional)

- Inductance Measurement: Ensures winding integrity.

- Resistance Measurement: Confirms copper wire accuracy.

- Polarity Test: Confirms correct winding direction (optional)

Pass/fail coils are automatically separated.

Benefit: Guarantees only 100% tested products are sent forward.

8. Auto Unloading

- Finished coils are placed into bins or trays for packaging.

- Rejected coils are moved to a separate tray for operator review.

Benefit: Streamlined unloading reduces manual handling.

SQ Ferrite Core Flat Wire Automatic Production Line | Winding Soldering Testing Machine

Key Features of the Machine Line

-

High-Speed Flat Wire Winding – Precision control ensures consistency in every winding.

-

Full Automation – From core loading to unloading, no human touch is required.

-

600–700 pcs/hour Output – Ideal for large-scale manufacturing.

-

Zero Defect Assurance – In-line testing ensures only good units pass.

-

Single Operator Requirement – Operator only refills materials and monitors production.

-

Compact Integration – Machines are linked in a line, saving factory space.

-

Durability & Reliability – Industrial-grade construction designed for 24×7 use.

Applications of SQ Ferrite Core Flat Wire Transformers

- Switch Mode Power Supplies (SMPS)

- Automotive Electronics (ECUs, chargers, sensors)

- Electric Vehicle (EV) Chargers & Converters

- Telecom Power Systems

- Industrial Automation Drives

- Medical Electronics

- LED Lighting Drivers

- Consumer Electronics (TVs, Laptops, Set-Top Boxes)

Why Choose Deptronics Technologies?

-

Authorized Indian Partner of Diggers (China), global leaders in automatic coil winding machinery.

-

Proven Expertise in handling installation, training, and after-sales support.

-

No Return Policy but Guaranteed Installation – Machines are installed directly at client’s factory.

-

Direct Connection with Manufacturer – Customization requests handled efficiently.

-

Local Indian Support – Quick service response, eliminating downtime.

Frequently Asked Questions (FAQ)

Q1. How many operators are required for this machine line?

Only one trained operator is needed to refill materials and monitor the line.

Q2. What is the average production efficiency?

The line consistently delivers 600–700 finished pieces per hour.

Q3. Can it handle different SQ core sizes?

Yes, the machine can be customized for different SQ ferrite core dimensions.

Q4. How is product quality ensured?

Every unit undergoes in-line soldering and high-voltage testing, with automatic pass/fail sorting.

Q5. What is the machine’s payback period?

On average, ROI is achieved within 6–12 months, depending on production volume.

Q6. Is Deptronics the direct supplier in India?

Yes. Deptronics Technologies is the official partner, offering supply, installation, and support in India.

Conclusion: The Smart Investment for Modern Factories

The SQ Ferrite Core Flat Wire Automatic Production Line is not just a machine—it is a complete transformation solution for transformer manufacturers. With 600–700 pcs/hour output, near-zero human intervention, and guaranteed consistency, it enables companies to meet rising global demand while cutting labor costs.

For Indian manufacturers aiming to stay competitive, automation is no longer optional—it is essential. By partnering with Deptronics Technologies, clients gain access to cutting-edge technology, reliable service, and long-term productivity benefits.

For machine inquiries, pricing, or customization options, contact Deptronics Technologies today!

DEPTRONICS TECHNOLOGIES

📌 Contact Person: Deepanshu Saxena

📞 WhatsApp/ Mobile: +91-8800622761

🌐 Website: https://coilwinder.in/

📧 Email: [email protected]

Reviews

There are no reviews yet.