Why Automation is Important in Solenoid Coil Winding

In manual winding, each coil’s accuracy depends on the operator’s skill and concentration. Over time, fatigue or small human errors can cause variations. Automation solves all these problems. The solenoid coil winding machine runs through a PLC-controlled program, ensuring identical coils every time.

Here’s why automation has become a necessity:

- Consistency: Every coil has identical turns and tension.

- Speed: Multi-spindle machines can produce hundreds of coils per hour.

- Cost Saving: Less manpower required for the same output.

- Quality Control: Reduced rejections and wastage.

- Data Repeatability: Parameters can be saved and reused for future batches.

For manufacturers supplying to automotive and industrial OEMs, these factors directly impact customer satisfaction and profitability.

How the Solenoid Coil Winding Machine Works

The machine operates through a completely automatic cycle. The process can be divided into the following steps:

Step 1 – Bobbin Loading

Empty bobbins are placed on the loading fixture or tray. Depending on machine configuration, this can be manual, semi-automatic, or fully automatic with robotic pickup.

Step 2 – Copper Wire Threading

The copper wire passes through a series of tension controllers, guides, and nozzles to maintain perfect control before winding starts.

Step 3 – Bobbin Winding

Automatic wrap copper wire on starting terminal pin, the spindle rotates at high speed while the traverse system moves horizontally to distribute the wire layer by layer.

Each spindle follows its programmed design, including turn count, direction, speed, and layer gap.

Step 4 – Auto Stop and Cut

Once the winding is complete, the system automatically stops, wrap on terminal pins, cuts the wire, and may even perform auto taping or auto soldering depending on the setup.

Step 5 – Unloading

Finished coils are ejected automatically to a collection tray or conveyor for the next process like soldering, varnishing, or testing.

This fully automated sequence ensures smooth, nonstop production with minimum supervision.

Machine’s Working Video

Technical Specifications

| Parameter | Specification |

|---|---|

| Number of Spindles | 12 / 16 / 20 / 24 |

| Wire Diameter | 0.05 mm – 0.5 mm |

| Maximum Bobbin Diameter | Up to 30 mm |

| Spindle Pitch | 50–55 mm |

| Spindle Drive | High-precision servo motors |

| Traverse Movement | Programmable servo system |

| Winding Direction | CW / CCW |

| Speed | Up to 12,000 RPM (depends on wire and bobbin size) |

| Tension Control | Magnetic or Servo |

| Power Supply | AC 220V, Single Phase, 50Hz |

| Air Pressure | 4–6 kg/cm² |

| Optional Attachments | Auto loading, wire twisting, taping unit, enamel remover, etc. |

These specifications can vary depending on model and customer requirements.

Machine Construction and Key Components

A solenoid coil winding machine may look simple from the outside, but inside it is built with precise mechanical and electrical components working together:

| Component | Description |

|---|---|

| Main Frame | Rigid structure ensuring vibration-free performance. |

| Spindles | Mounted on precision shafts for uniform winding. |

| Servo Motors | Control spindle rotation and wire guide movement. |

| Magnetic / Servo Tensioners | Maintain consistent wire pull. |

| Wire Guide System | Ensures even layer distribution and neat winding. |

| Control Panel | PLC with touchscreen for easy operation and design input. |

| Pneumatic Scissors | Automatically cut wires after each winding cycle. |

| Safety Covers & Sensors | Provide operator safety and prevent accidents. |

All these parts together ensure stable, accurate, and long-life machine performance.

Advantages of Using an Automatic Solenoid Coil Winding Machine

Here are some real benefits Indian manufacturers experience after adopting automation:

- Mass Production: Multiple coils wound at the same time.

- Uniform Quality: Every coil has the same winding pattern.

- Higher Output, Less Labour: A single operator can manage the whole process.

- Reduced Rejection: Constant tension means fewer broken wires or uneven coils.

- Flexibility: Easily adjustable for different bobbin types and coil designs.

- Data Storage: Save programs for repeated orders.

- Low Maintenance: Robust design ensures long-term reliability.

- Improved Safety: Enclosed design and automatic stops reduce accidents.

- Compact Design: Space-saving and easy to install in existing production setups.

- Better ROI: Payback within months due to productivity gain.

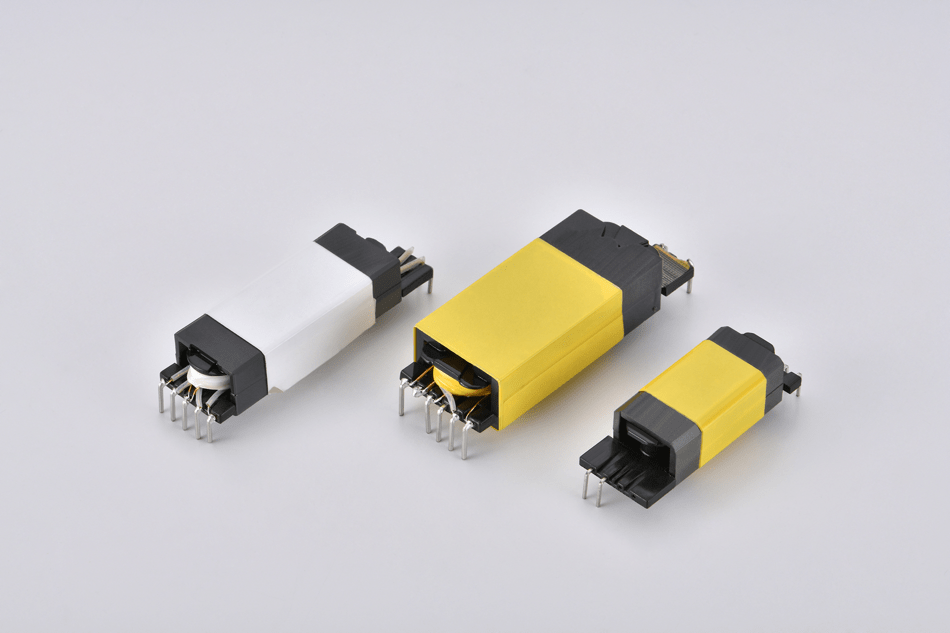

Optional Attachments and Add-ons

Depending on the production requirement, the machine can be fitted with several useful add-ons:

- Wire Twister Unit – For fine wire twisting or bifilar winding.

- Auto Taping System – Automatically applies insulation tape after winding.

- Auto Soldering Station – Flux and solder the terminal pins automatically.

- Copper Enamel Remover – Removes wire coating before soldering.

- Servo Tensioner – Real-time wire tension monitoring and precise tension control

- Fully Automatic Loading-Unloading – Robotic pickup and tray management for mass production lines.

These add-ons make the system versatile for any coil manufacturing unit — whether small-scale or large OEM supplier.

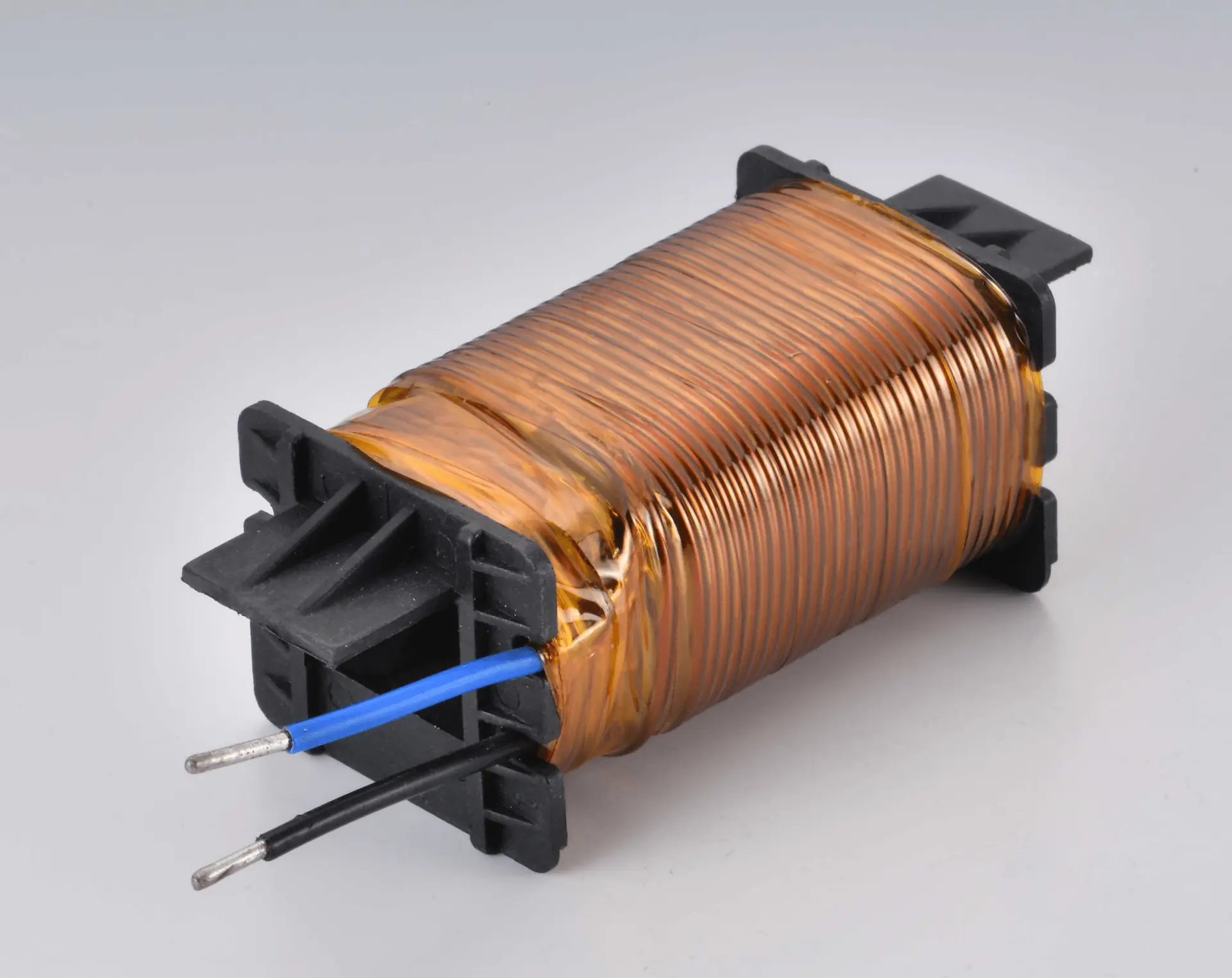

Industries Using Solenoid Coil Winding Machines

The applications are very wide. Such machines are used by:

- Automotive component manufacturers – Fuel injector and valve coils

- Home appliance companies – Door locks, washing machine valves, RO solenoids

- Hydraulic and pneumatic equipment makers – Control coils

- Electronic device manufacturers – Relays and sensors

- Industrial automation OEMs – Machine solenoid actuators

Basically, wherever electromagnetic motion is needed, solenoid coils are there — and this machine plays a vital role in making them.

Return on Investment (ROI)

Let’s take a basic calculation for better understanding.

| Particular | Manual Winding | Automatic 12 Spindle Machine |

|---|---|---|

| Operators Required | 10 persons | 1 person |

| Production / Hour | 1200 coils | 1400 coils |

| Monthly Output (8-hour shift) | 2,40,000 coils | 2,80,000 coils |

| Labor Cost | ₹1,50,000+ / month | ₹15,000 / month |

| Defects / Rejections | 5–10% | <1% |

| Payback Period | – | 10–12 months |

This simple table shows how investing in one automatic machine can multiply production and profits in a short time.

DepTronics Technologies – Your Trusted Supplier in India

DepTronics Technologies is one of India’s well-known companies dealing in automatic coil winding and production line machines.

We specialize in solenoid coil winding, relay coil production lines, and transformer winding automation for industrial and OEM clients.

What Makes DepTronics Different:

- Experience: Deep understanding of coil production needs in India.

- Support: Installation, programming, and after-sales service available nationwide.

- Customization: Machines configured as per coil size, wire type, and production volume.

- Spare Availability: Local stock of essential parts to minimize downtime.

- Training: On-site and remote training for operators.

- Customer Satisfaction: Many reputed Indian industries rely on DepTronics for their production line machines.

Our aim is simple – to provide affordable, advanced, and reliable automation solutions that help Indian manufacturers compete globally.

If your business is ready to take the next step toward solenoid coil production excellence, contact DepTronics Technologies today and transform your manufacturing line into a world-class automated setup.

DEPTRONICS TECHNOLOGIES

Contact : Deepanshu Saxena

WhatsApp/Mobile : +91-8800622761

Email : [email protected]

For mass production of Solenoid coils, check our “Solenoid Coil Automatic Production Line for Mass Manufacturing”

Reviews

There are no reviews yet.