Key Functions of the Relay Coil Winding Machine

The automatic relay coil winding machine is designed to cover the complete production cycle with minimal human input. Its functions include:

-

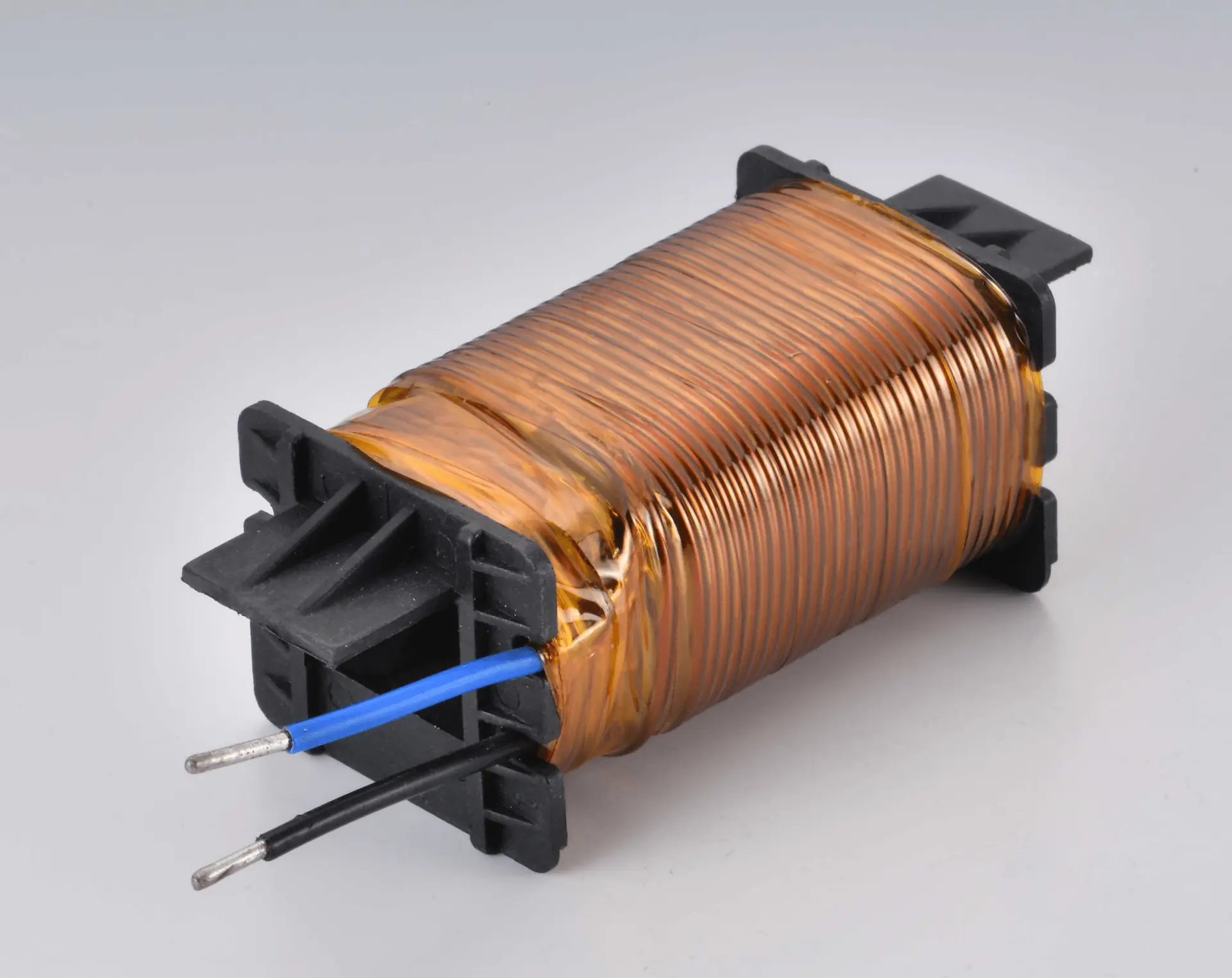

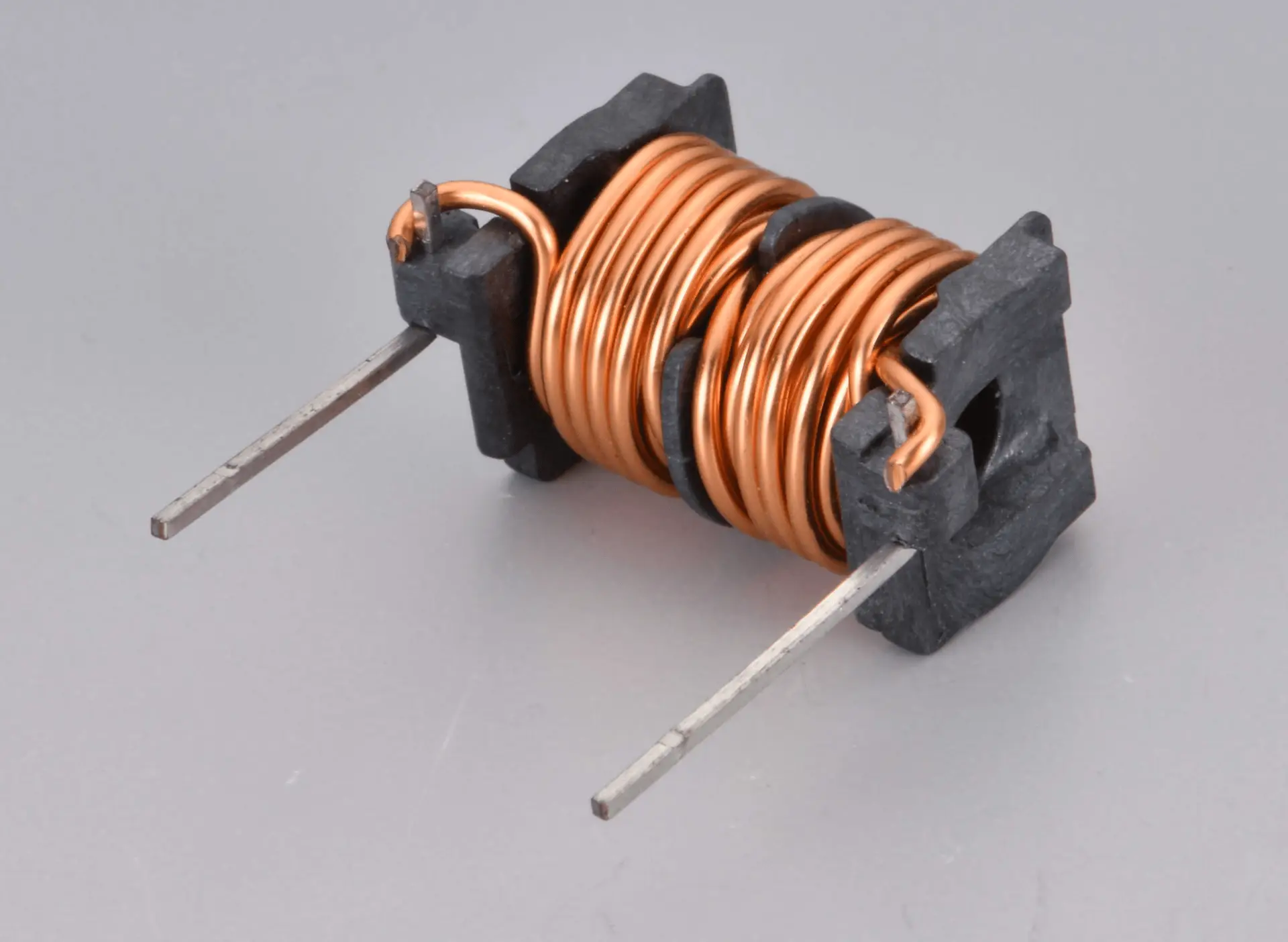

Automatic Loading of Bobbins

A feeding tray system positions empty bobbins onto winding fixtures. This reduces manual labor and ensures that the winding stations are always ready for operation. -

Simultaneous Multi-Spindle Winding

All 12 spindles (or more, depending on the chosen configuration) operate simultaneously. This parallel winding process significantly boosts output compared to single-spindle machines. -

Magnetic Tension Control

Maintaining consistent tension is vital for the electrical properties of the finished coil. Magnetic tensioners automatically adjust to wire diameter and maintain balance throughout the winding process. -

Support for Fine and Thick Wires

The machine can handle copper wire ranging from ultra-fine (0.02 mm) to relatively thick (0.5 mm). For sensitive fine wires, the optional twister unit helps avoid breakage. -

Automatic Unloading

After winding, finished coils are automatically unloaded and collected in trays, ensuring smooth workflow and reducing the risk of coil damage. -

PLC-Controlled Interface

A user-friendly touch screen allows operators to configure coil designs, set winding parameters, monitor progress, and run diagnostics with ease.

Working Video of Relay Coil Winding Machine

Working Principle of the Relay Coil Winding Machine

The machine’s operation is based on a continuous automated cycle that integrates loading, winding, and unloading. Here’s how it works step by step:

1. Auto Loading

Operators simply place empty bobbins onto the feeding plate. The fixture mechanism automatically picks them up and positions them onto the mandrels.

2. Multi-Spindle Winding

Once loaded, all 12 spindles start winding simultaneously. Each spindle follows programmed settings — whether single-layer, multi-layer, or cross-winding. Different coils can be programmed for varied turns, ensuring flexibility.

3. Wire Tension Control

Magnetic tensioners maintain steady wire pull, ensuring the coil’s structure is precise and uniform. For clients needing even finer control, servo tensioners can be integrated.

4. Automatic Unloading

As soon as the winding is completed, the coils are automatically ejected into the collection tray. This step reduces handling time and eliminates human error.

5. Continuous Production

The machine resets immediately for the next cycle. With cycle times ranging between 25–35 seconds (depending on the number of turns), the system can achieve remarkable hourly throughput.

Technical Specifications of Relay Coil Winding Machine

To understand the machine’s capabilities, here’s a professional summary of its technical specifications:

| Specification | Details |

|---|---|

| Number of Spindles | 12, 16, 20, or 24 (customizable based on production needs) |

| Motors | High-precision servo motors |

| Wire Tensioners | Magnetic tensioners (servo tensioners optional on request) |

| Spindle Gap | 50.6 mm |

| Maximum Bobbin Size | 30 mm swing diameter |

| Winding Direction | Clockwise (CW) / Counter-clockwise (CCW) |

| Spindle Stop Accuracy | ±0.1 degree |

| Copper Wire Range | 0.02 mm to 0.5 mm |

| Wire Anchoring Angle | 0° / 90° (motorized rotation available if required) |

| Power Supply | Single-phase AC 220V, 50Hz |

| Power Consumption | Approx. 2.5 kW |

| Air Pressure Requirement | 4–6 kgf/cm² |

| Optional Devices | Wire twisting unit, pneumatic cutter, servo tension meter, copper enamel remover |

| Optional Functions | Fully auto loading/unloading, automatic taping, auto wire clipping, waste wire discharge |

Why Automation in Relay Coil Winding is Critical

Relay manufacturing is one of the most competitive markets in the electrical component industry. Manual winding methods not only slow down production but also result in inconsistencies that affect the relay’s reliability. By adopting a relay coil winding machine, manufacturers gain:

- High-Speed Production: Multiple spindles working together reduce cycle times drastically.

- Superior Quality: Automated winding eliminates irregularities caused by manual error.

- Cost Efficiency: Fewer operators are needed, reducing labor costs.

- Flexibility: Machine programs can be quickly adapted to new coil designs.

- Reliability: Consistent winding ensures relays perform consistently in critical applications.

Cycle Time & Production Capacity

One of the most impressive advantages of the 12 Spindle Relay Coil Winding Machine is its speed. Thanks to simultaneous winding and automated loading/unloading, each cycle typically takes 25–35 seconds, depending on the programmed number of turns and wire thickness.

At this rate, the system can achieve a production capacity of 1,300 to 1,500 coils per hour, far outpacing conventional semi-automatic machines. This level of output makes the solution highly suitable for manufacturers supplying to large-scale relay industries, including automotive OEMs, home appliance companies, and consumer electronics.

Return on Investment (ROI) Analysis

Purchasing an advanced automatic relay coil winding machine is a capital-intensive decision. However, the ROI calculation shows that the payback period is surprisingly short compared to the long-term benefits.

- Initial Investment: Approx. ₹24–25 Lakhs (varies by spindle configuration and optional attachments).

- Labor Savings: A single automated machine can replace 10–12 manual operators, saving monthly wage costs.

- Production Output: 1,300–1,500 coils per hour ensures large-scale batch deliveries without hiring additional workforce.

- Defect Reduction: Automated winding maintains uniform tension and accuracy, leading to up to 90% fewer rejections.

- Payback Period: In most industrial setups, the payback period is 10–12 months of normal usage.

After the first year, every additional coil produced contributes directly to profit margins, making this machine a long-term asset for manufacturers.

Why Choose DepTronics Technologies for Relay Coil Winding Machines?

Purchasing a high-value machine is not just about the hardware; it is also about reliable after-sales support and service. DepTronics Technologies has built a strong reputation as one of India’s leading suppliers of automatic coil winding and production line machines.

Here’s why industries trust DepTronics:

- Nationwide Coverage: Installation, training, and service support available across all major industrial hubs in India.

- Local Stock of Spares: Essential spare parts are readily available to minimize downtime.

- Expert Engineers: Highly skilled service engineers are available for installation, troubleshooting, and training.

- Custom Programming: Machines can be programmed according to specific relay coil designs.

- Strong OEM Partnership: As the official Indian partner of Diggers (China), DepTronics provides direct access to the manufacturer’s expertise.

When businesses invest in DepTronics machines, they are not just buying equipment — they are entering into a long-term partnership backed by local expertise and international standards.

Final Words

The Relay Coil Winding Machine represents the future of relay coil production — combining automation, accuracy, and efficiency into one compact solution. With options ranging from 12 to 24 spindles, it is designed for manufacturers looking to scale production without compromising on quality.

By investing in this machine, industries benefit from:

- Faster production cycles

- Reduced labor dependency

- Improved coil quality

- Lower rejection rates

- A short ROI period

As India’s trusted partner for automatic coil winding machines, DepTronics Technologies ensures clients not only receive cutting-edge machines but also reliable service, spare support, and customization tailored to their needs.

If your business is ready to take the next step toward relay coil production excellence, contact DepTronics Technologies today and transform your manufacturing line into a world-class automated setup.

DEPTRONICS TECHNOLOGIES

Contact : Deepanshu Saxena

Mobile : +91-8800622761

WhatsApp : https://wa.me/918800622761

Email : [email protected]

Automatic Machine Production Line for Relay Coil Manufacturing in India

Sumit Raghav –

The structure quality of the machine is very good, professional company.