Machine Function and Operation

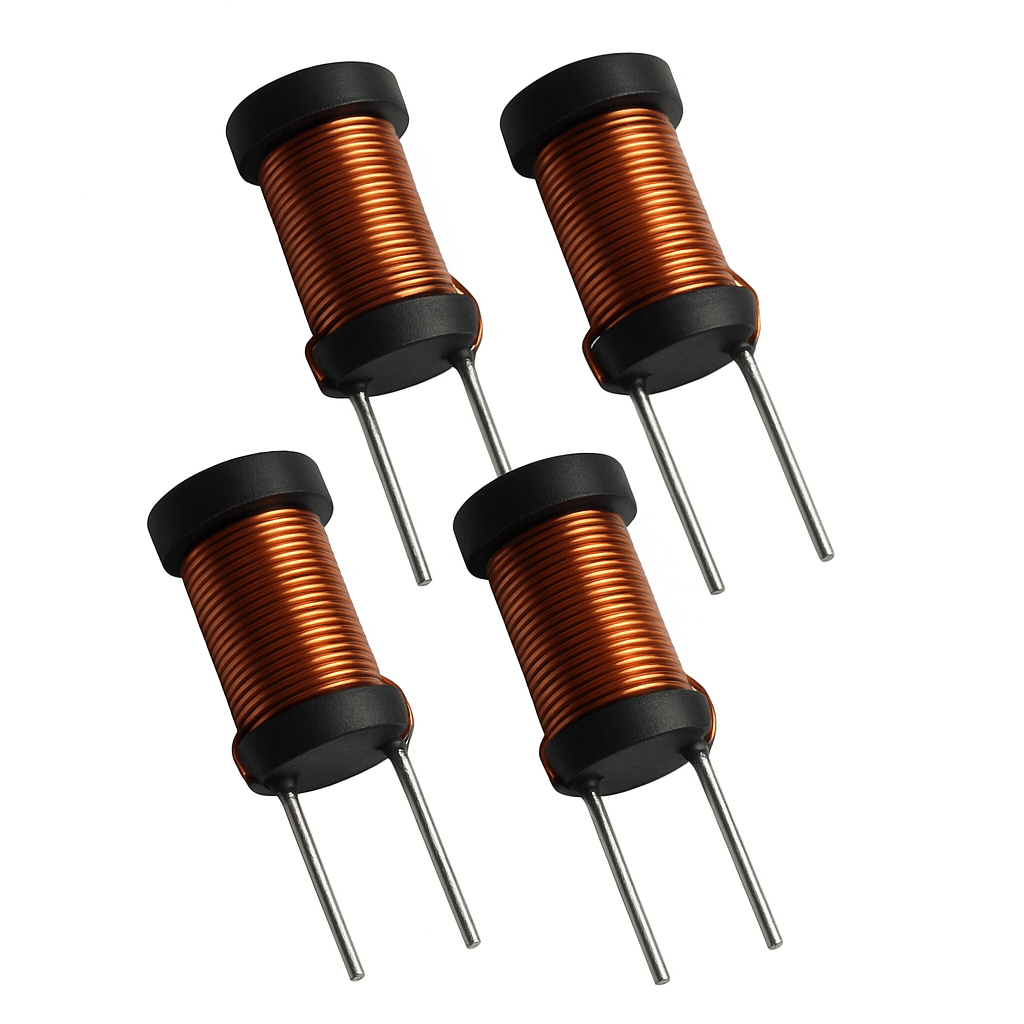

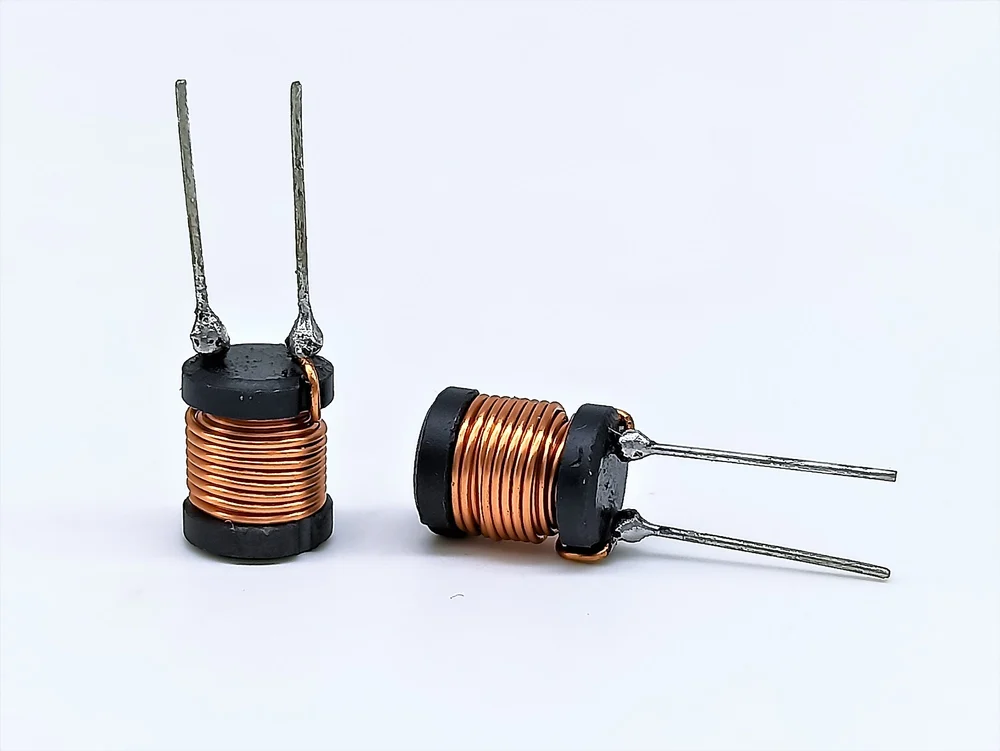

The machine performs automatic winding of copper wire on drum-type ferrite cores with precise pitch and layer control. Each spindle operates independently under synchronized servo control, allowing simultaneous winding of up to 12 cores at once.

Core Operations:

-

Automatic Core Loading: Operator needs to put blank drum core bobbins into loading fixture only.

-

Wire Positioning & Tensioning: Fine wire (typically 0.05–0.40mm) is guided through magnetic tensioners ensuring stable tension across all spindles.

-

Servo-Controlled Winding: Servo motors execute high-speed rotation, maintaining uniform turns and accurate wire layering on each drum core.

-

Automatic Unloading: Automatic unload all wound coils during start of next cycle.

All operations are programmable through a PLC + touchscreen HMI, allowing easy program recipe setup, storage of winding parameters, and real-time monitoring of speed, tension, and production count.

Technical Features

1. Multi-Spindle Servo Drive System

Each spindle is driven by servo motor with closed-loop feedback, ensuring precision and repeatability in wire placement and tension control.

2. High-Speed Production Output

With optimized motion control and minimal changeover time, the 12-spindle setup achieves significantly higher productivity compared to single or dual spindle models.

3. Programmable Winding Parameters

All parameters such as turns, wire pitch, start/stop angle, traverse width, XYZ axis movements and lead length are software-defined and stored in memory for repeated batch production.

4. Automatic Wire Clamping and Cutting System

A precision pneumatic cutting unit ensures smooth wire cut-off and soldering without manual interference.

5. Touchscreen HMI Control Panel

The operator interface provides intuitive control over program setup, diagnostics, production counter, and alarm monitoring.

6. Quick Fixture Change Design

Fixtures for different drum core sizes can be swapped within minutes, reducing downtime during product changeovers.

7. Rigid Machine Construction

The mechanical base is fabricated with vibration-resistant steel, ensuring stability during high-speed winding.

8. 24×7 Industrial Duty Design

Equipped with cooling fans, durable bearings, and sealed lubrication points for continuous long-duration operation.

Machine Working Principle

The Drum Core Inductor Winding Machine follows a fully automated sequence controlled by a motion controller.

Here’s the working principle in industrial terms:

-

The fixture turret holds 12 ferrite drum cores aligned with the wire feeding nozzles.

-

Upon start command, the servo spindle motor initiates rotation, while the traverse axis moves precisely to guide wire along the ferrite drum’s surface.

-

The tension controller continuously monitors resistance and adjusts brake force dynamically.

-

After completion of the preset turns, the wire cutter and soldering head engage simultaneously to terminate both ends.

-

The finished components are released pneumatically and moved to the output tray or testing section.

The system can achieve winding speeds up to 100–12000 RPM per spindle, depending on the wire gauge and inductor dimensions.

Working Videos :

Reviews

There are no reviews yet.