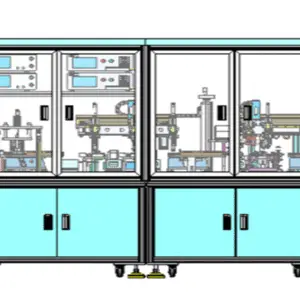

Key Features:

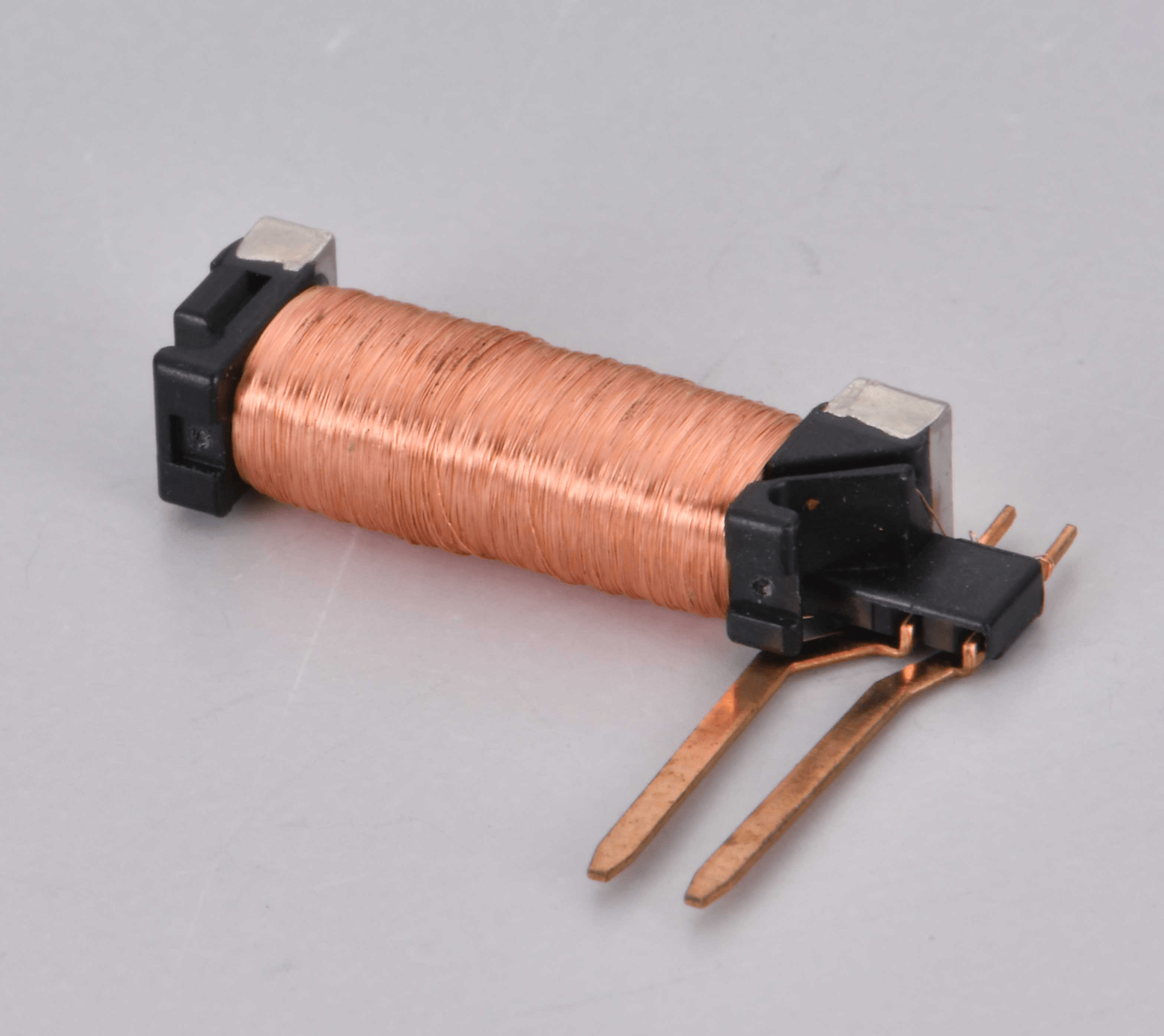

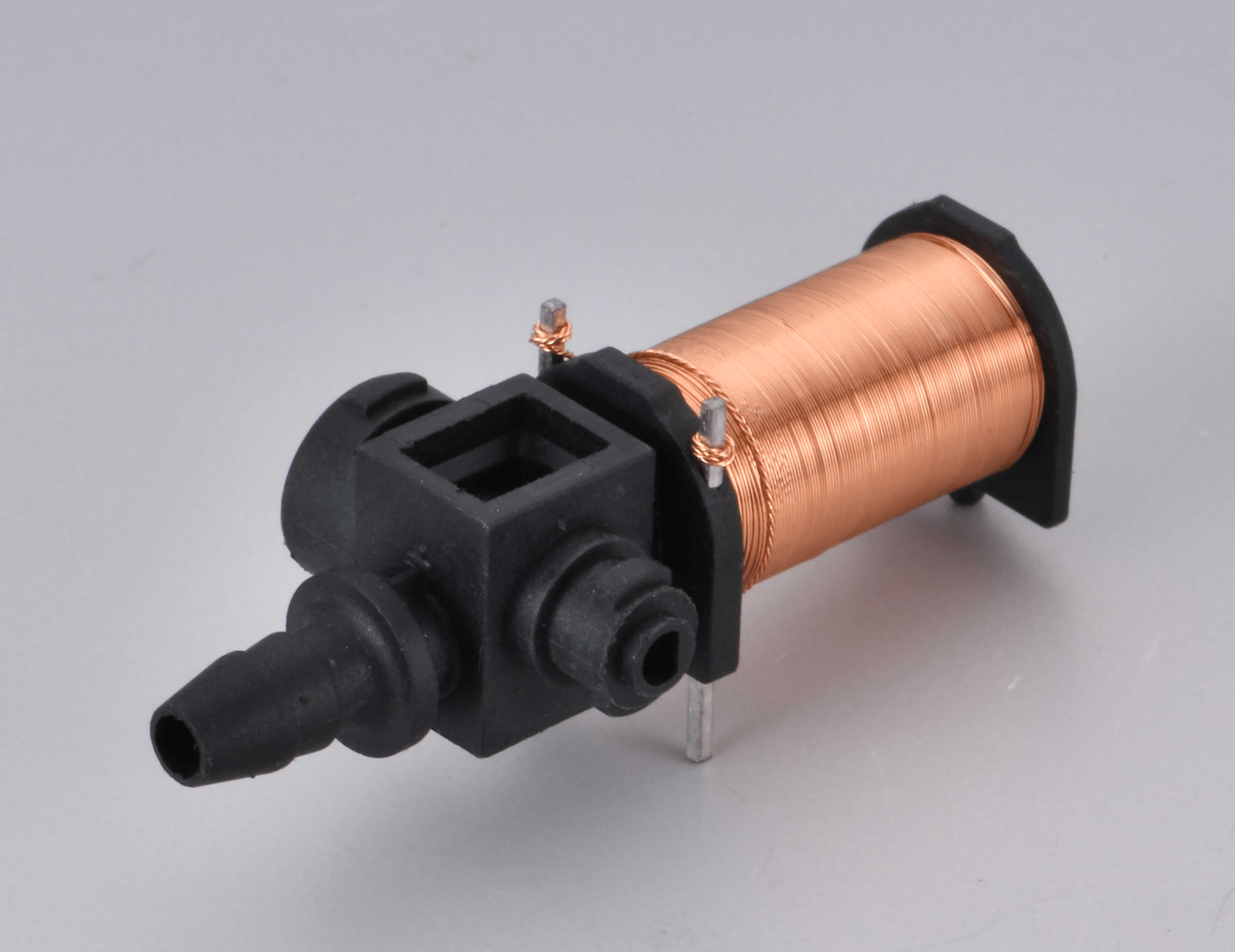

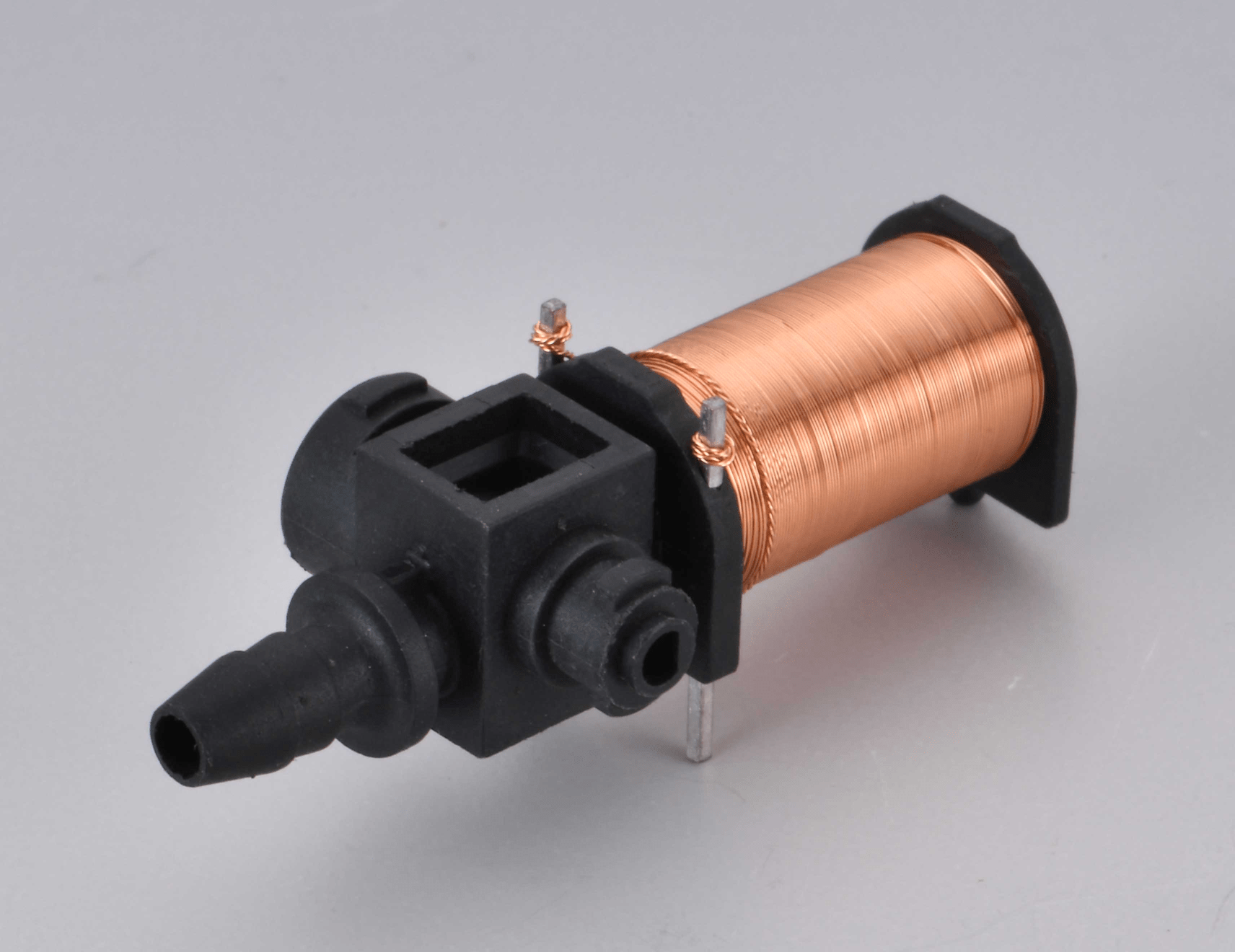

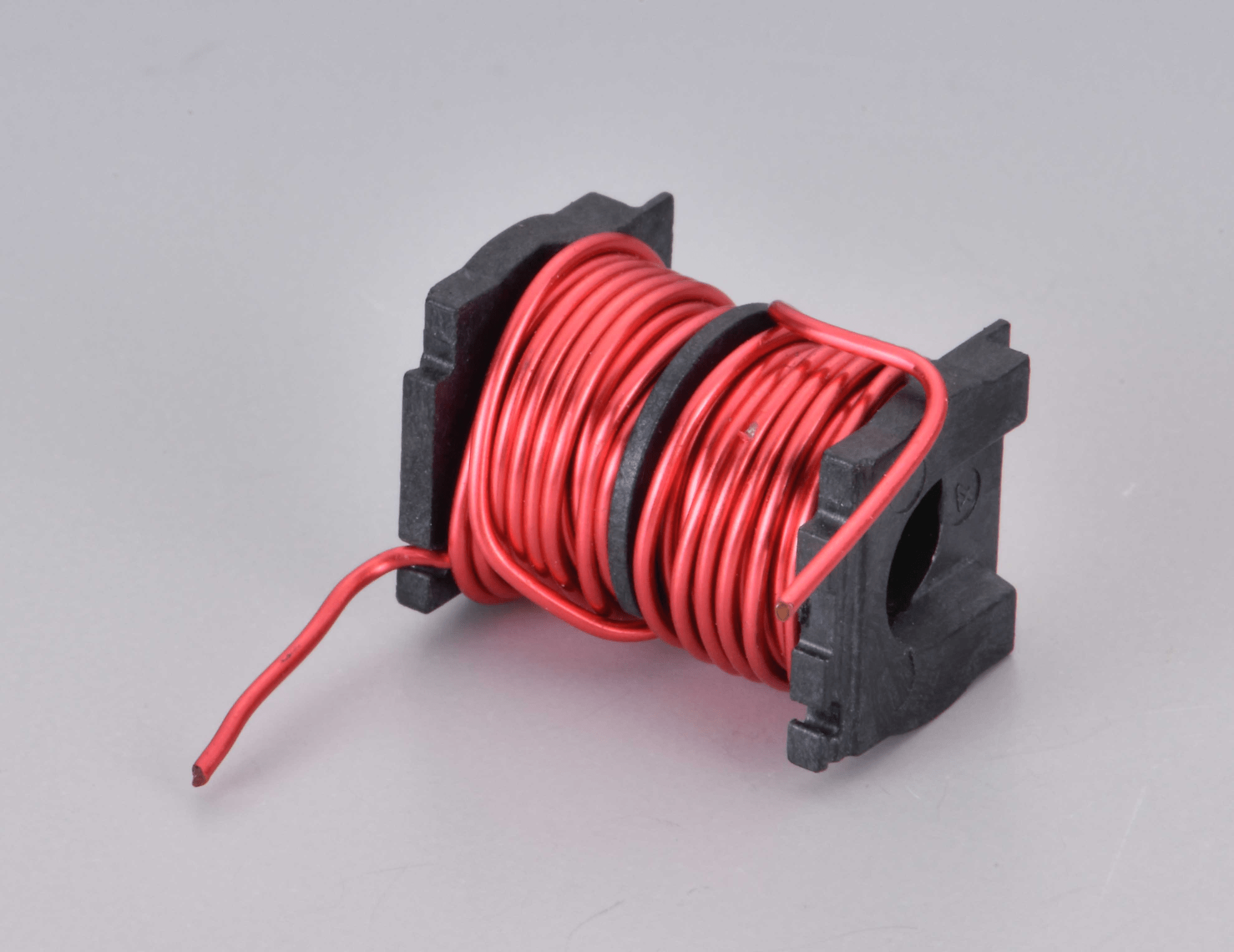

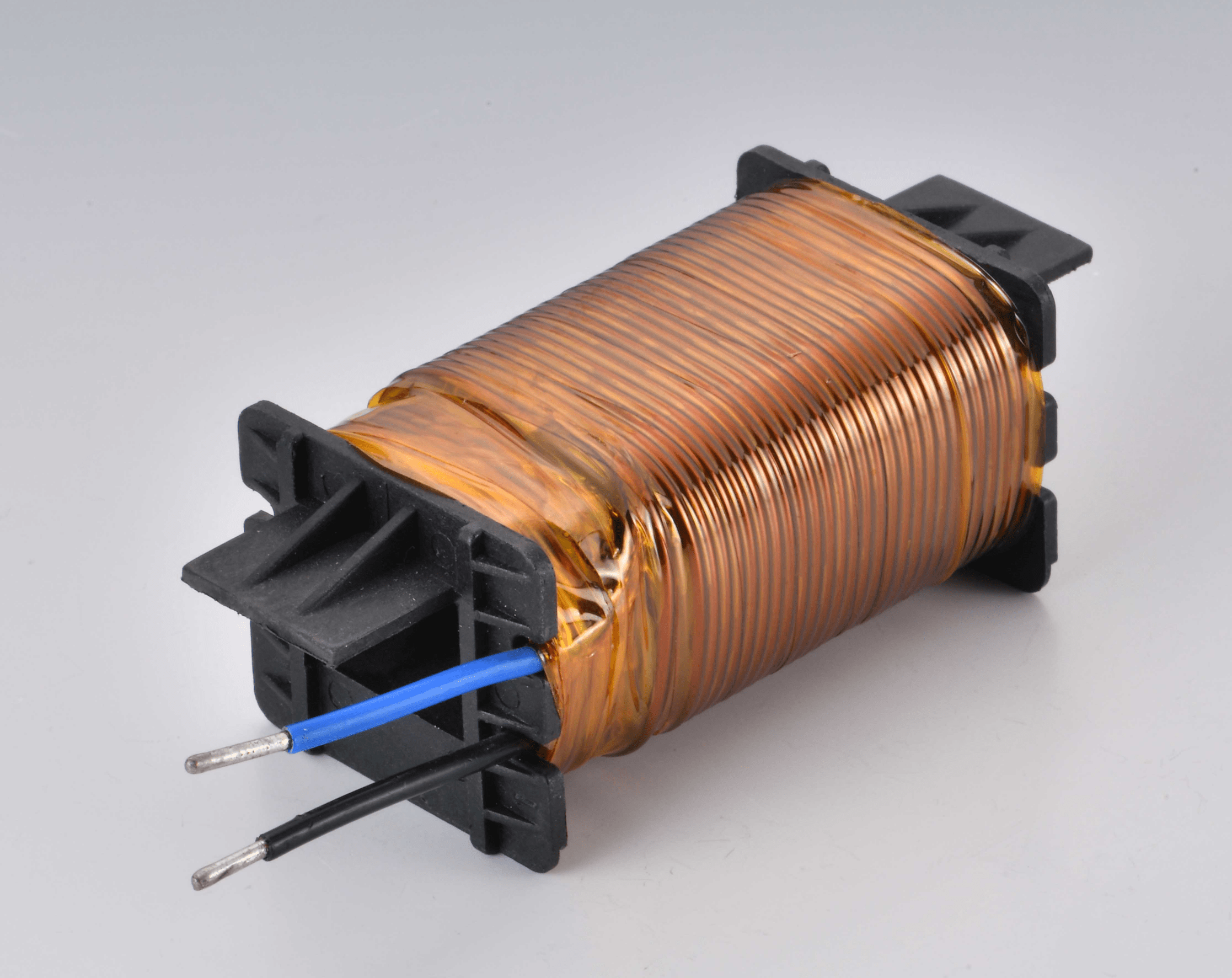

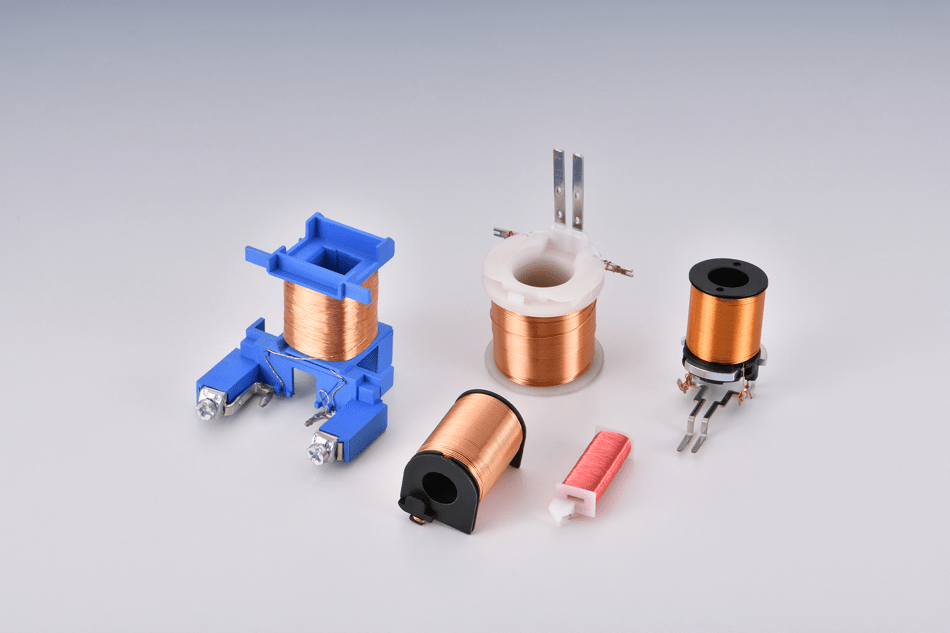

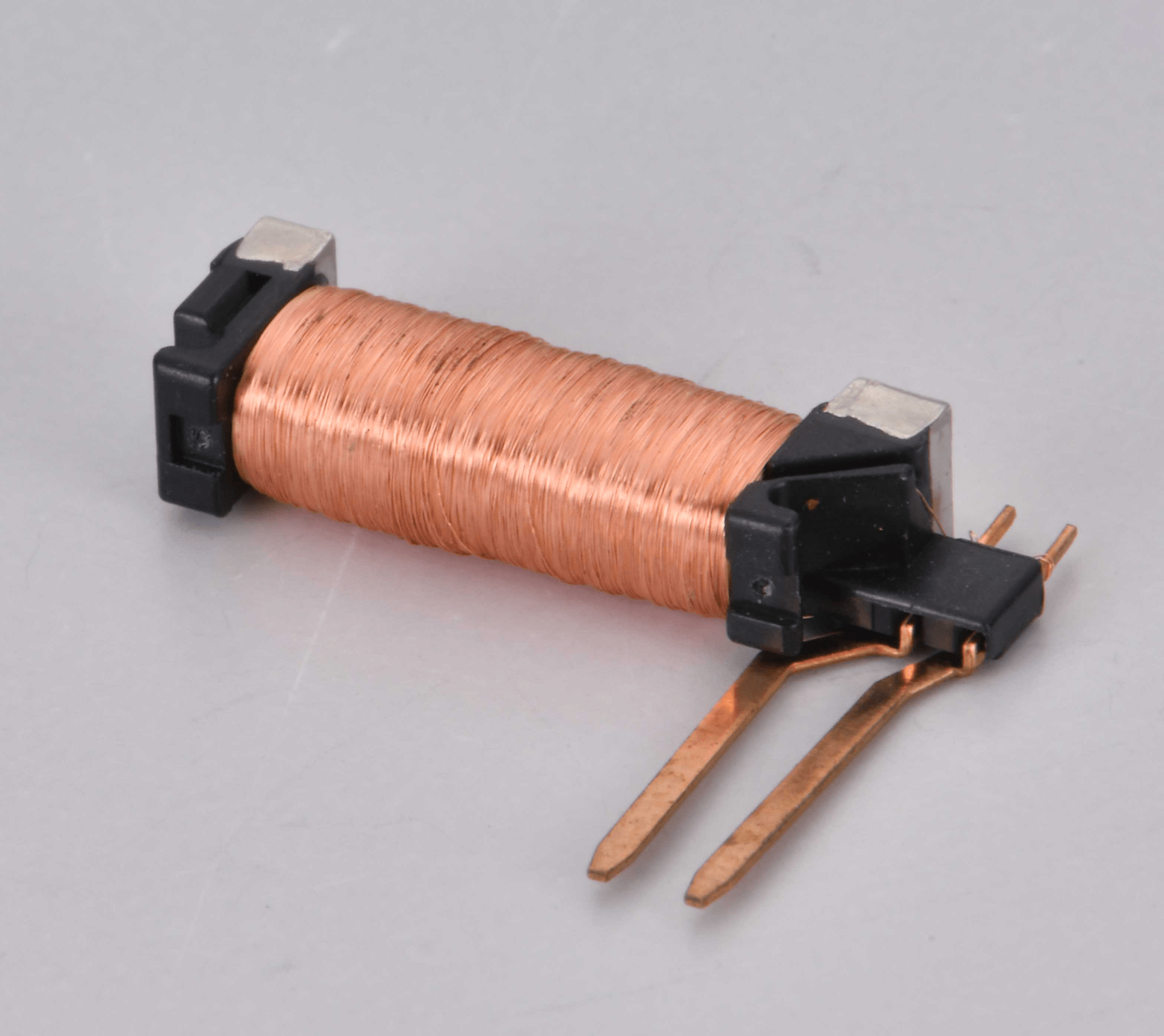

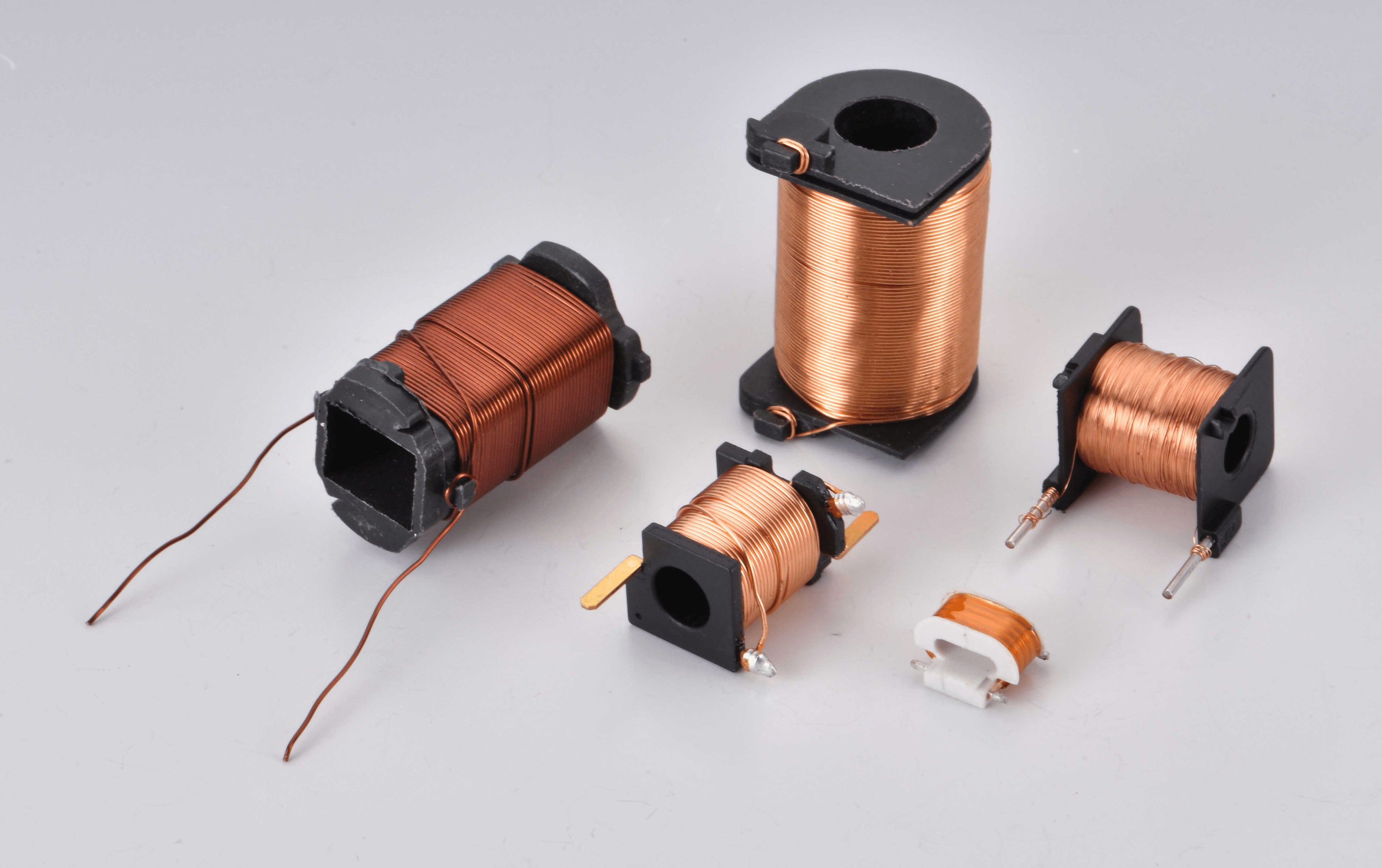

- Automatic Coil Winding: The machine automates the winding process of copper or other conductive wire around a bobbin to create the relay’s coil. This precision is crucial for ensuring proper electrical characteristics and efficient performance of the relay.

- High Precision and Speed: Automotive relay coils require precise winding to achieve the correct number of turns and maintain uniform tension on the wire. The machine operates at high speeds to meet the production demands of automotive manufacturers.

- Wire Tension Control: The machine includes systems for maintaining consistent wire tension during the winding process. This helps prevent wire breakage and ensures that the coils are evenly wound.

- Programmability: Modern HDVC relay winding machines are programmable, allowing for different winding patterns, wire gauges, and coil specifications. Operators can adjust settings for different relay models and production batches.

- Automated Bobbin Insertion: Some machines come with automated systems for inserting the bobbin around which the coil is wound, enhancing automation and reducing the chances of human error.

- Inspection Systems: The machines often include inspection cameras or sensors that detect winding defects, such as misalignment, tangles, or breaks, ensuring that only high-quality coils are produced.

- Cooling and Insulation: After winding, the coil may undergo a cooling or curing process, particularly if insulation is involved. This ensures that the coil is electrically insulated and ready for use in automotive applications.

- Safety Features: Since the machine operates with high-speed mechanical components and electrical systems, it typically includes safety features like emergency stops, protective covers, and sensors to prevent accidents.

Applications:

- Electric Vehicle (EV) and Hybrid Vehicle Systems: High-voltage relays are critical in EVs for controlling battery packs, charging systems, and high-voltage components.

- Automotive Control Systems: Relay coils are used in automotive control units to manage power to various components, such as motors, actuators, and sensors.

- HVDC Power Systems: These winding machines may also be used to manufacture coils for relays used in high-voltage direct current (HVDC) transmission, a key technology for long-distance power distribution.

Benefits:

- Increased Productivity: Automating the winding process significantly boosts production speed and consistency.

- Precision: The machine ensures that the coils meet strict tolerances, which is essential for the performance and safety of automotive electrical systems.

- Reduced Labor Costs: Automation reduces the need for manual labor, lowering operational costs.

- Consistency: It ensures every coil produced is identical, reducing variability that could lead to malfunctions or failures in the relay.

More details, please contact freely :

DEPTRONICS TECHNOLOGIES

Contact : Deepanshu Saxena

Mobile : +91-8800622761

WhatsApp : https://wa.me/918800622761

Email : [email protected]

Reviews

There are no reviews yet.