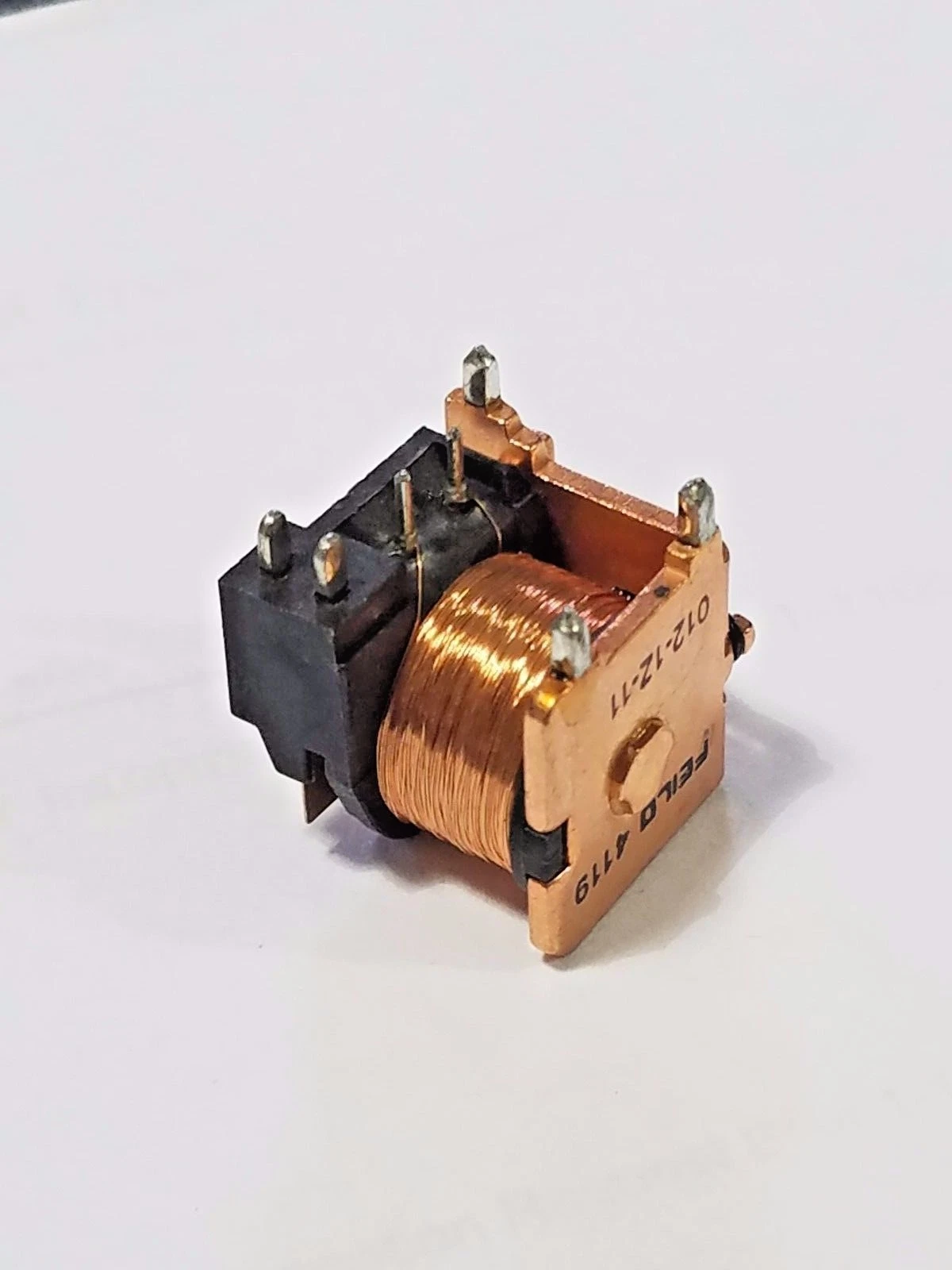

Overview of the Automatic Relay Coil Winding Machine

The machine includes a highly efficient auto loading and auto unloading system where operators only place the blank relay bobbins into the loading rack; after this, the machine handles every remaining operation:

- Auto loading the bobbin into mandrel

- Wire wrap on the first terminal pin

- High-speed winding according to programmed turns

- Wire cutting

- End wrapping on the final terminal pin

- Automatic unloading of finished parts

Optional attachments and upgrades make the system even more powerful:

- Twister unit for fine wire twisting

- Automatic taping unit for insulation and finishing

- Magnetic or servo-based tensioners

- Copper enamel removal system

- Programmable pneumatic nipper scissors

- Automatic waste wire discharge

- CCD camera inspection (optional)

With these automation units, the machine becomes a complete solution for high-end relay manufacturers who demand accuracy, consistency, and industrial-level mass production.

In summary, the automatic relay coil winding machine is engineered to:

- Multiply productivity using multi-spindle parallel winding

- Enhance precision with servo-controlled motion and programmable settings

- Reduce defects using stable tension control and automated pin wrapping

- Improve workflow with automatic loading and unloading

- Save manpower by minimizing operator involvement

- Deliver consistent and high-quality coils suitable for global OEM standards

For manufacturers supplying to automotive, consumer electronics, home appliance, telecom, and industrial automation sectors, this machine is an essential investment.

Working Process of the Automatic Relay Coil Winding Machine

The machine follows a continuous automated cycle. Once the program is set and blank bobbins are loaded, the entire winding process runs independently with minimal operator involvement.

Below is a complete step-by-step explanation of the machine’s working principle:

Step 1: Operator Loading of Blank Bobbins

The process begins with a simple operator task: loading empty relay bobbins into the fixture tray.

No specialized skill is required — the operator only needs to place the bobbins correctly.

From this point onward, the machine takes control.

Step 2: Auto Loading to Mandrel Tools

The mechanical feeder picks bobbins from the loading plate and automatically mounts them onto the mandrel tools.

Auto loading ensures:

- Exact bobbin placement

- No misalignment

- Reduced handling time

- Zero chances of human-induced defects

This step significantly improves efficiency compared to manual loading where precision and speed vary from operator to operator.

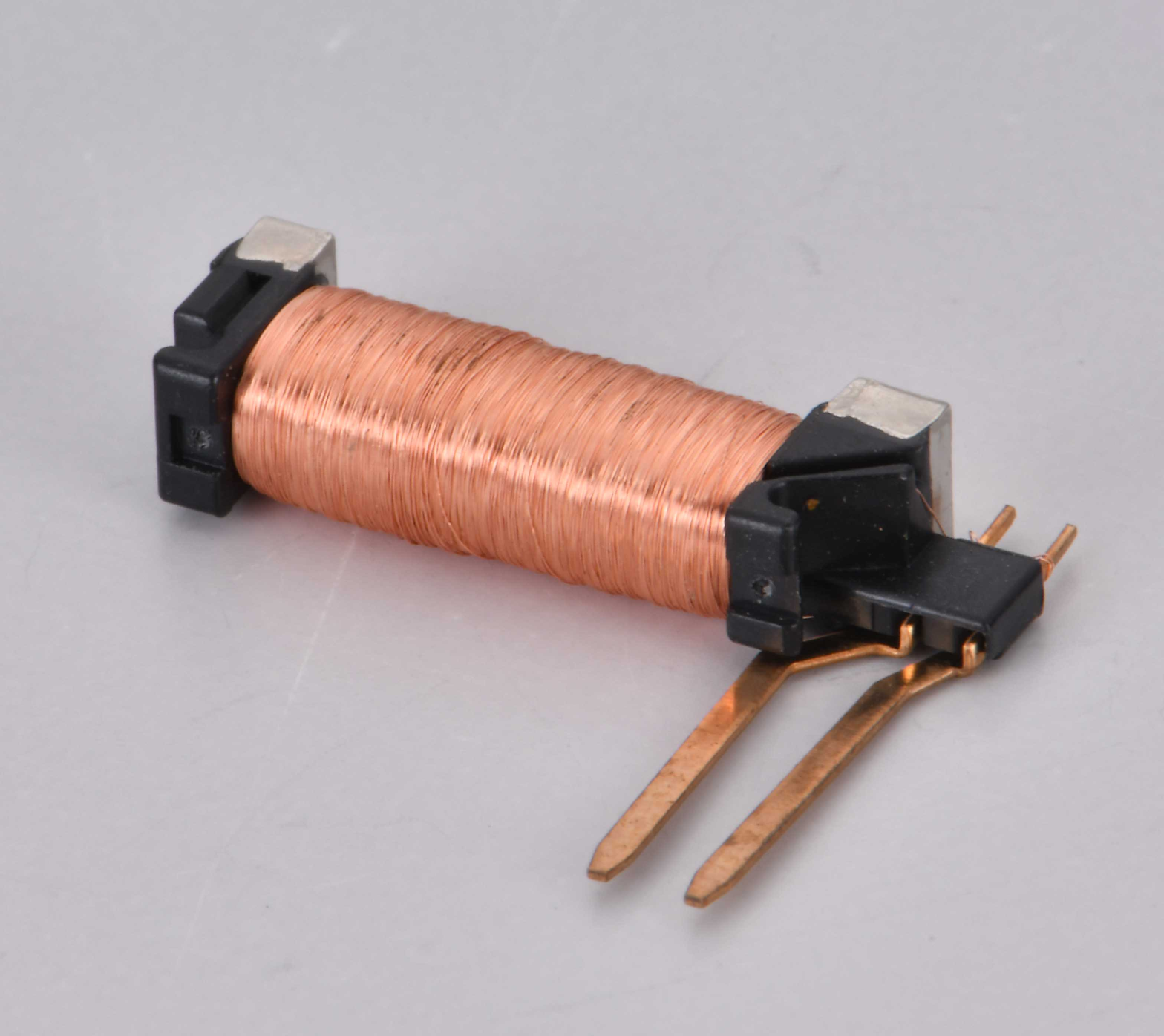

Step 3: Wire Hooking & Start Wrap on First Terminal Pin

Once the bobbin is fixed onto the mandrel:

- The wire feeding nozzle positions itself near the first terminal pin

- The system performs a tight wrapping around the initial pin

- Proper anchoring is ensured using servo-controlled positioning

This is essential for achieving a solid electrical connection and mechanical stability.

Step 4: High-Speed Copper Wire Winding

With the start wrap completed, the main winding process begins.

The 12 spindles rotate simultaneously according to the programmed parameters:

- Winding direction: CW or CCW

- Number of turns

- Speed (RPM)

- Layer distribution (single-layer or multi-layer)

- Winding pattern (normal, cross-winding, distributed layer winding)

Each spindle follows the exact program, ensuring all wound coils are identical and meet design standards.

The machine achieves:

- High precision

- Very low variation in electrical characteristics

- Uniform coil density

- Highly repeatable production

Step 5: End Wrap on Terminal Pin

After completing the required number of turns, the machine automatically positions the wire for terminal wrapping.

Key operations:

- The spindle stops at an accuracy of ±0.1°

- The wire is wrapped securely around the final pin

- A stable mechanical and electrical connection is ensured

For additional quality, an optional copper enamel remover can strip insulation for a clean pin connection.

Step 6: Wire Cutting and Automatic Unloading

The pneumatic or servo-controlled scissors cut the wire precisely.

Then the finished wound bobbin is ejected into a collection tray.

Benefits of auto unloading:

- Fast cycle recovery

- Smooth workflow

- Reduced coil damage

- Eliminates manual handling

Immediately after unloading, the machine resets for the next cycle, enabling continuous production.

Working Video :

Cycle Time Summary

Typical cycle time for most relay coils:

-

30–40 seconds per cycle (depends on total number of winding turns)

Production capacity per hour:

-

1,200 – 1,400 coils/h (depends on total number of winding turns)

This makes the machine suitable for mass production and large OEM supply chains.

Key Functions of the Relay Coil Winding Machine

The versatility and performance of this machine come from a wide range of intelligent features. Below are the primary functions that make it a preferred choice for industrial manufacturers.

1. Automatic Loading of Bobbins

The auto-loading tray ensures smooth feeding of bobbins to the mandrels.

It reduces operator work and ensures consistent workflow in small and large factories alike.

2. Simultaneous Multi-Spindle Winding

All 12 spindles (or more in custom configurations) work at the same time.

This parallel operation multiplies total production output by 12 compared to a single-spindle system.

3. Magnetic Tension Control

Stable tension is essential for coil consistency.

The magnetic tensioners:

- Control wire pull

- Prevent wire breakage

- Maintain coil uniformity

- Support variable-speed winding

Optional servo tensioners provide even higher precision.

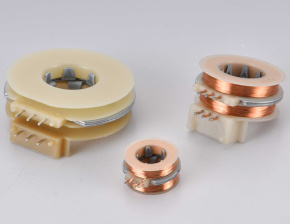

4. Support for Fine & Thick Wires

The machine supports a wide wire range:

- Ultra-fine wires: 0.06 mm

- Thicker wires: 0.6 mm

This makes it suitable for various relay models and winding specifications.

5. Automatic Unloading System

After winding, the bobbin is automatically ejected into the collection bin.

This small but powerful function reduces cycle time and ensures that the workflow remains uninterrupted.

6. User-Friendly PLC Touch Screen Interface

Operators can easily:

- Set winding parameters

- Select program recipe

- Monitor real-time production

- Run diagnostics

- Adjust spindle speed

- Track cycle time

This eliminates complexities and allows fast setup.

Technical Specifications of Relay Coil Winding Machine

| Specification | Details |

|---|---|

| Number of Spindles | 12 / 16 / 20 / 24 (customized) |

| Motors | High-precision servo motors |

| Wire Tensioners | Magnetic or optional servo type |

| Spindle Gap | 50.6 mm |

| Max Bobbin Size | 30 mm swing |

| Winding Direction | CW / CCW |

| Spindle Stop Accuracy | ±0.1° |

| Copper Wire Range | 0.02–0.5 mm |

| Wire Anchoring Angle | 0° / 90° |

| Power Supply | AC 220V, 50Hz |

| Power Consumption | 2.5 kW approx. |

| Air Pressure | 4–6 kg/cm² |

| Optional Devices | Twister, cutter, enamel remover |

| Optional Automation | Auto loading/unloading, taping, clipping, waste wire discharge |

This technical framework ensures that the machine is capable of handling even the most demanding relay applications.

Cycle Time & Production Capacity

Cycle Time (Average): 30–35 seconds

Factors affecting cycle time:

- Number of turns

- Wire gauge

- Coil size

- Winding pattern

- Pin wrapping requirement

Production Capacity

- 1,200 – 1,400 coils/hour

- 9,000 – 11,000 coils per 8-hour shift

- 234,000 – 286,000 coils per month (26 days)

This high throughput makes the machine suitable for OEMs supplying:

- Automotive relay manufacturers

- Home appliance brands

- EMS companies

- Motor and solenoid manufacturers

- Electronics component suppliers

ROI (Return on Investment)

Despite being a high-value industrial machine, the ROI is exceptionally strong because of:

1. Labor Savings

One automatic machine can replace 10–12 manual operators, reducing monthly labor costs significantly.

2. High Productivity

At 1,200–1,400 coils per hour, the machine ensures fast batch deliveries without requiring more workers or more machines.

3. Reduced Rejections

Automated winding maintains uniform tension and accuracy, reducing rejection rates by up to 90%.

Why Choose DepTronics Technologies?

DepTronics Technologies is India’s trusted supplier of automatic coil winding and production line machines, offering complete solutions for relay manufacturing companies.

1. Nationwide Service Support

Engineers available across India for installation, training, and service.

2. Local Spares Availability

Essential spare parts are always stocked to reduce downtime.

3. Custom Programming

Machines can be programmed according to customer-specific relay models.

4. Professional Team

Highly experienced technical staff for training and troubleshooting.

5. Strong OEM Partnership

- Direct factory support

- Priority spares

- Advanced programming expertise

- Competitive pricing

DepTronics is not just a vendor—it is a long-term technology partner for manufacturers looking to scale coil production.

Final Summary

The Automatic Relay Coil Winding Machine (12 Spindle) is a highly advanced system built for mass relay coil production. With:

- Multi-spindle parallel winding

- Automatic loading & unloading

- Precision servo motors

- Magnetic tension systems

- Programmable controls

- Optional automation modules

…it is a complete solution for manufacturing high-quality relay coils at industrial scale.

Manufacturers looking for speed, consistency, and low cost per coil will benefit tremendously from this machine.

DepTronics Technologies delivers not only the machine but also complete Indian service support, ensuring smooth production for years to come.

Contact Us

For machine inquiries, pricing, or customization options, contact us today!

DEPTRONICS TECHNOLOGIES

📌 Contact Person: Deepanshu Saxena

📞 WhatsApp/ Mobile: +91-8800622761

🌐 Website: https://coilwinder.in/

📧 Email: [email protected]

For mass production of relay coils, check our “Automatic Production Line for Mass Manufacturing of Relay Coils”

Krishnajeet –

They are expert in machine line and they also taken training session during machine installation time, and also teach programming of the machine. much better experience