Why Automation in Inductor Manufacturing Is Essential

1. Market Demand

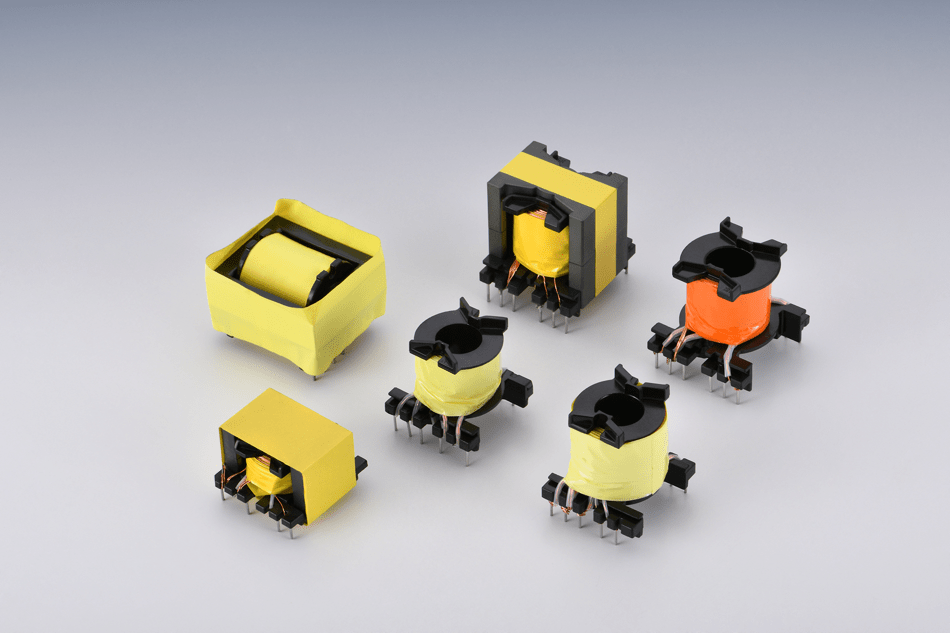

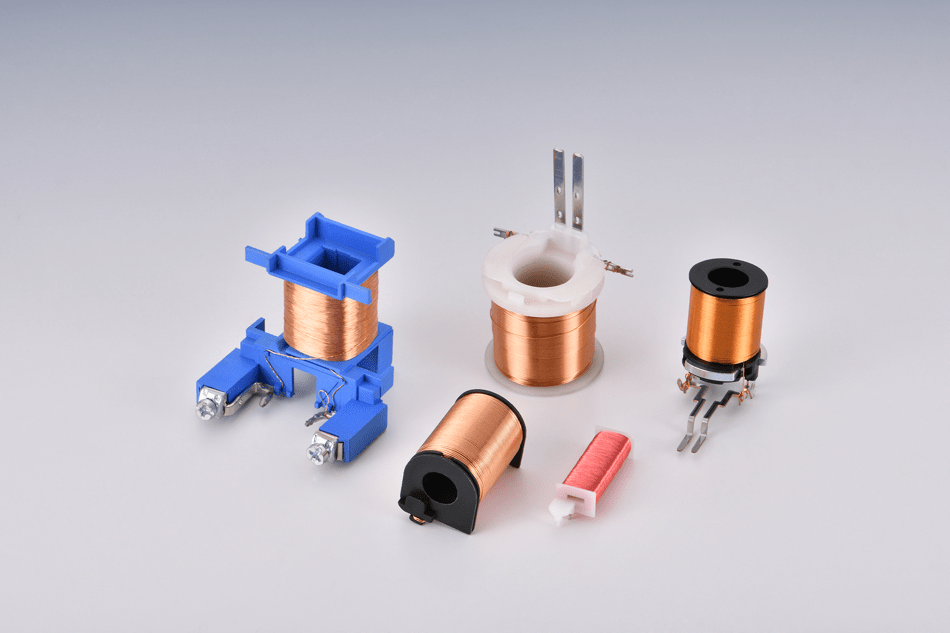

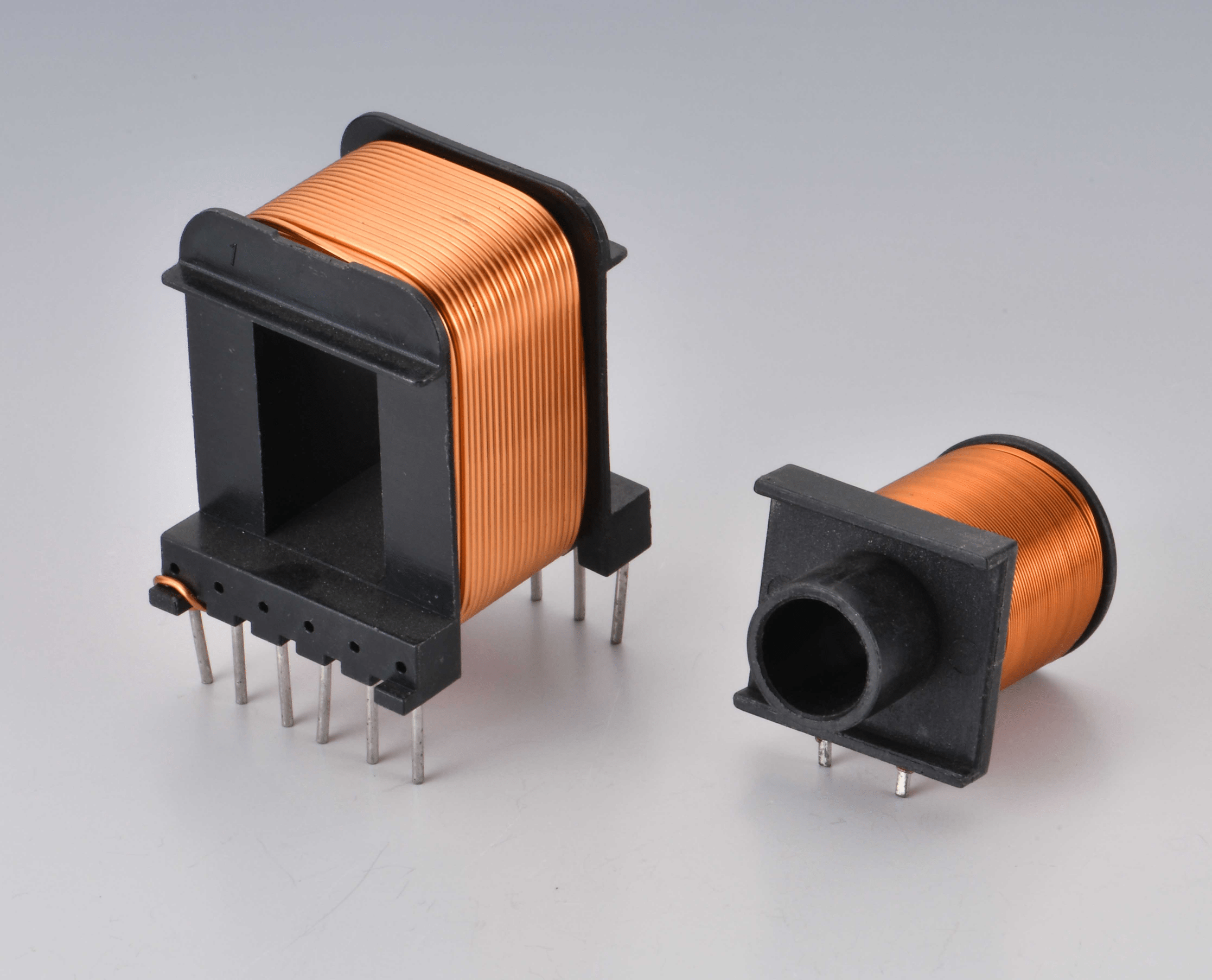

The rapid adoption of Switched Mode Power Supplies (SMPS), renewable energy systems, LED lighting, electric vehicle chargers, and communication equipment has created an unprecedented demand for inductor coils. EE series inductors, especially in sizes EE10 to EE25, are used in millions each year across industries.

2. Limitations of Manual Production

-

Inconsistent winding quality due to human error.

-

High dependency on skilled operators.

-

Limited daily output (one operator requires ~30–35 seconds per coil).

-

Increased production costs due to labor dependency.

3. Global Competitiveness

International manufacturers are moving towards fully automated mass production. To remain competitive, Indian manufacturers must adopt automation to ensure scalability, quality, and lower per-unit costs.

4. Precision Requirements

Modern electronics demand tight tolerance in inductance values. Small deviations in winding turns, wire tension, or placement can result in defective components. Automation ensures repeatable accuracy.

In summary, automation is no longer optional—it is a necessity for any serious player in the electronics component manufacturing sector.

Overview of the Automatic Inductor Coil Winding Machine

The Deptronics 12 Spindle Automatic Inductor Coil Winding Machine is engineered to meet the high-volume production needs of the electronics industry. Its modular and robust design allows manufacturers to customize the system with optional units, while its advanced control system ensures flexibility across various coil designs.

Key Features

-

12 Spindles – Winding of 12 coils simultaneously in one cycle.

-

Automatic Bobbin Loading & Unloading – Operator simply places blank bobbins into the loading plate.

-

Programmable Motion Control – 5-axis servo motor control with HMI-based programming.

-

Optional Taping Attachment – Provides insulation wrapping after winding.

-

Optional Twister Unit – Designed for handling fine-gauge copper wires.

-

Pneumatic Nipper Cutter – Cuts heavy copper wires with precision.

-

Cycle Time – 15–20 seconds per cycle, depending on wire gauge and turns.

-

After-Sales Support – On-site installation, training, and nationwide technical service.

Working Video :

Technical Specifications

| Parameter | Specification |

|---|---|

| Machine Type | Automatic Inductor Coil Winding Machine |

| Supported Coil Types | EE10, EE13, EE16, EE20, EE25 |

| Spindles | 12 Spindles (winds 12 coils simultaneously) |

| Cycle Time | 15–20 seconds (depends on wire size & turns) |

| Operation Axes | 5-axis servo motor controlled |

| Control System | Advanced motion controller |

| HMI Interface | Touch panel with password protection |

| Program Storage | Multiple winding programs can be saved |

| Optional Units | Taping, Twister, Pneumatic Cutter |

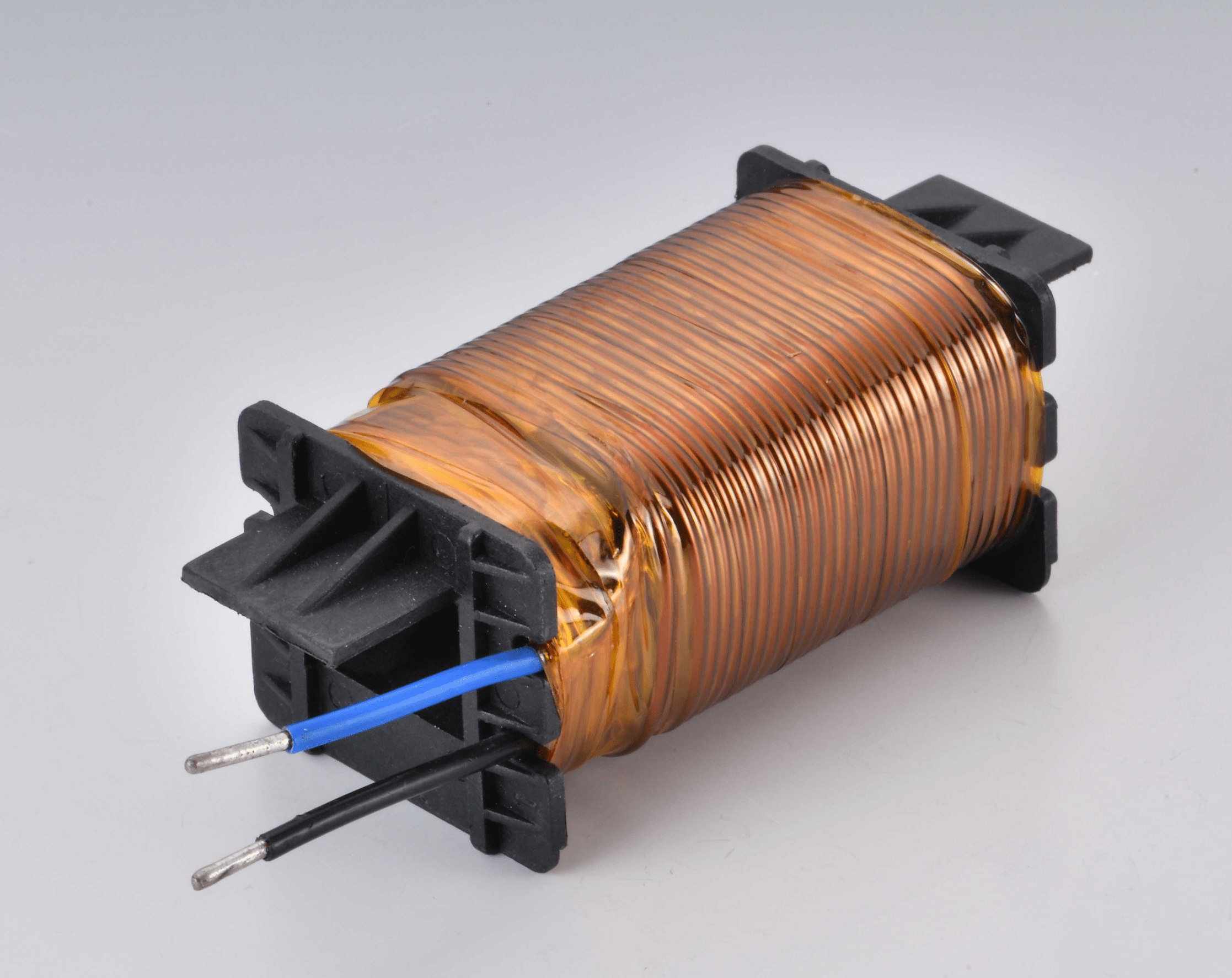

| Wire Compatibility | Fine gauge to heavy copper wires |

| Sensors | Airtac / SMC reed sensors |

| Pneumatics | Airtac / SMC cylinders |

| Cutting Mechanism | Pneumatic nipper cutter |

| Structure | Fine & strong mechanical structure |

| Power Supply | AC 220V / 50Hz |

| Warranty | 1 Year standard |

| Service Support | Pan-India installation, training & AMC |

Working Principle – Step by Step

-

Bobbin Loading

The operator places blank bobbins into the loading plate. No manual fixing into spindles is required. -

Automatic Loading into Spindles

The machine automatically transfers bobbins from the plate into spindle fixtures. -

Winding Process

-

12 spindles begin winding simultaneously.

-

Wire tension and turns are controlled by servo motors.

-

Winding programs can be customized for different designs.

-

-

Optional Twisting

-

For ultra-thin wires, twisting prevents breakage.

-

The twister unit can be added on demand.

-

-

Optional Taping

-

Coils can be wrapped with tape for insulation.

-

Automated taping ensures uniform finish.

-

-

Wire Cutting

-

Pneumatic nipper cutter trims the wire.

-

Heavy-gauge wires are handled safely.

-

-

Unloading

-

Finished coils are unloaded automatically.

-

Machine resets for the next cycle

-

Cycle Time & Productivity

-

Cycle Time: 15–20 seconds for 12 coils.

-

Output Per Hour:

-

At 15 seconds/cycle → 2880 coils/hour.

-

At 20 seconds/cycle → 2160 coils/hour.

-

-

Daily Production (16 hours):

-

Between 34,560 and 46,080 coils/day.

-

This makes the machine ideal for mass production requirements.

ROI (Return on Investment)

Manual Winding (1 Operator)

-

Cycle time: 30–35 seconds per coil.

-

Hourly Output: ~103–120 coils.

-

Daily Output (16 hours): ~1,648–1,920 coils.

Automatic Winding (Deptronics 12 Spindle)

-

Cycle Time: 15–20 seconds for 12 coils.

-

Hourly Output: 2,160–2,880 coils.

-

Daily Output: 34,560–46,080 coils.

Efficiency Comparison

-

Automatic machine produces 22× more coils per day.

Example ROI Calculation

-

Average coil value = ₹2.5 per piece.

-

Manual Production: 1,800 coils/day × ₹2.5 = ₹4,500/day revenue.

-

Automatic Production: 40,000 coils/day × ₹2.5 = ₹1,00,000/day revenue.

Thus, depending on configuration and production demand, ROI can be achieved within 6–12 months.

Deptronics as Your Automation Partner

Deptronics Technologies has been a trusted partner in automation machinery manufacturing for more than two decades.

Our Strengths

-

25+ years of automation expertise.

-

Custom-built solutions tailored to client needs.

-

High-quality components (Airtac/SMC pneumatics, advanced motion controllers).

-

Nationwide service network.

After-Sales Support

-

Installation & Training – On-site setup and operator training.

-

Spare Parts Availability – Genuine spare parts supplied promptly.

-

Remote Support – Audio/video call troubleshooting.

-

On-Site Support – Quick technical visits when required.

-

Warranty – 1-year standard coverage.

-

Extended AMC – Annual Maintenance Contracts available.

Final Thought

The Deptronics Automatic Inductor Coil Winding Machine is a state-of-the-art solution for manufacturers aiming to achieve high-speed, precision-controlled, and cost-effective production of EE10–EE25 inductors.

With its 12 spindle simultaneous winding system, automatic bobbin handling, optional taping and twisting units, and advanced servo-driven control, the machine delivers unmatched productivity while minimizing manpower requirements.

Backed by robust after-sales service and 25 years of expertise, Deptronics ensures that clients receive not only a machine but also a long-term automation partner.

For electronic manufacturers, component suppliers, and power supply industries, investing in this machine is not just a purchase—it is a strategic step towards scalability, profitability, and global competitiveness.

Automatic Ferrite Inductor Coil Winding Machine

FAQ Section

-

Which inductor sizes are supported?

EE10, EE13, EE16, EE20, and EE25. -

What is the machine’s daily production capacity?

34,000–46,000 coils/day. -

How many operators are needed?

Only one operator for bobbin loading. -

Is the taping unit included?

It is optional, provided on demand. -

Can the machine handle fine-gauge wires?

Yes, with an optional twister unit. -

What about heavy copper wires?

Pneumatic nipper cutter handles them effectively. -

How many programs can be stored?

Multiple programs can be saved on HMI. -

What is the warranty period?

One year standard warranty. -

Is after-sales support available across India?

Yes, Deptronics provides pan-India service. -

Can ROI be achieved quickly?

Yes, within 6–12 months depending on production demand.

Contact Us

For machine inquiries, pricing, or customization options, contact us today!

DEPTRONICS TECHNOLOGIES

📌 Contact Person: Deepanshu Saxena

📞 WhatsApp/ Mobile: +91-8800622761

🌐 Website: https://coilwinder.in/

📧 Email: [email protected]

Reviews

There are no reviews yet.