Overview of the Machine

A 12‑spindle contactor coil winding machine is an automated production system that simultaneously winds 12 identical coils in a single cycle. Each spindle is fitted with tooling that holds the bobbin or former, guides the copper wire, and controls the turns and winding pattern. By working in parallel, the machine multiplies throughput while ensuring each coil is wound to the same electrical and mechanical specification.

Typical Production Capacity

- Simultaneous outputs per cycle: 12 coils

- Cycle time: Typically 30–40 seconds per cycle, depending on wire gauge (AWG/SWG), turns per coil, layer transitions, and winding pattern complexity.

- Theoretical throughput (example): With an average 35 seconds cycle time and continuous operation, a single 12‑spindle machine can produce approximately:

- 102 cycles per hour × 12 = 1,224 coils per hour

- Shift/day production depends on uptime and operator changeovers; realistic production after allowances (maintenance, loading/unloading, inspection) is typically 70–85% of theoretical.

Machine Composition — High Level

A standard Deptronics 12‑spindle automatic contactor coil winding machine typically includes:

- 12 winding spindles with independent tension control.

- Precision wire feeding mechanism with magnetic tensioner or servo‑driven payoffs, capstans, and programmable tension units.

- Programmable winding controller (PLC + HMI) that supports multiple winding programs, layers, and sequences.

- Automatic bobbin loading/unloading (optional) or manual loading stations.

- Punch/tap insertion and terminal bending (optional add‑ons depending on customer spec).

- Quality inspection ports, electrical test integration (LCR or DC resistance), and rejected parts conveyor.

- Safety enclosures with interlocks, emergency stops, and operator panels.

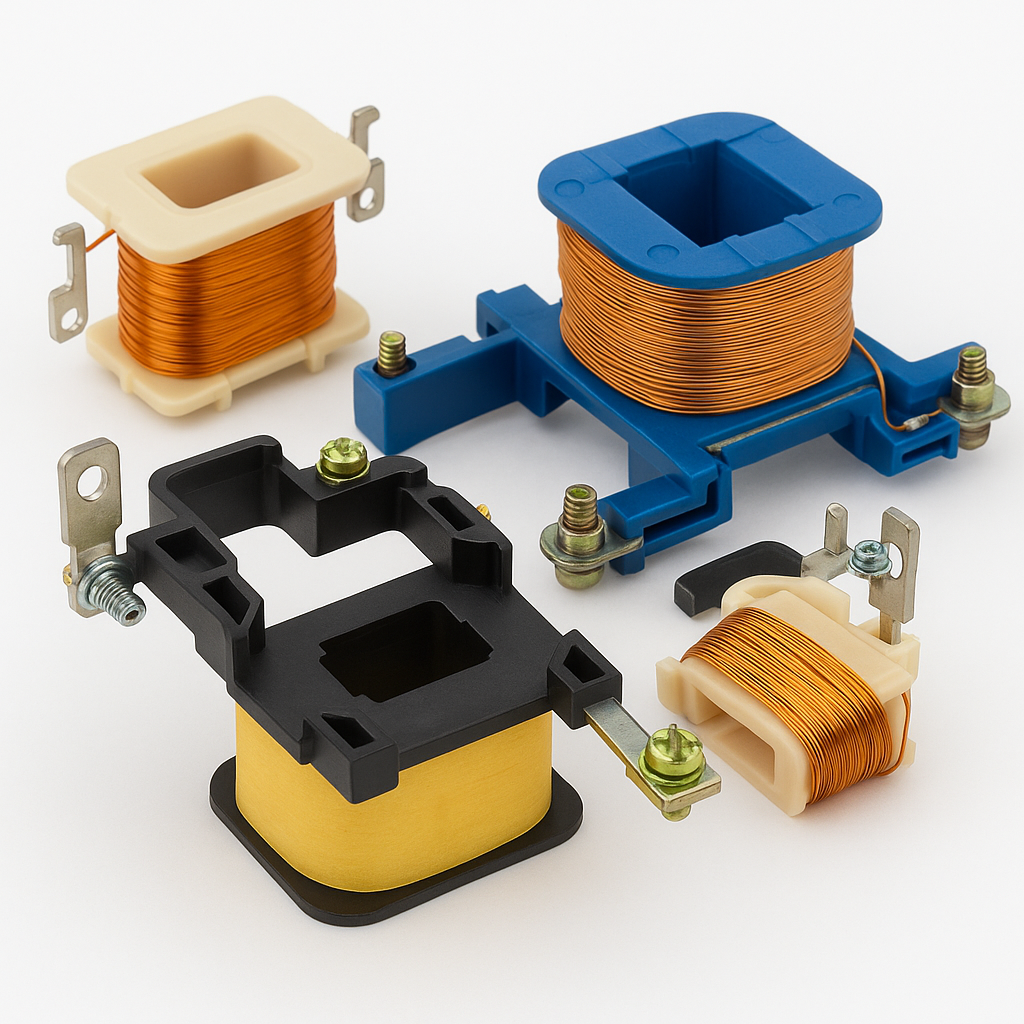

Typical Applications

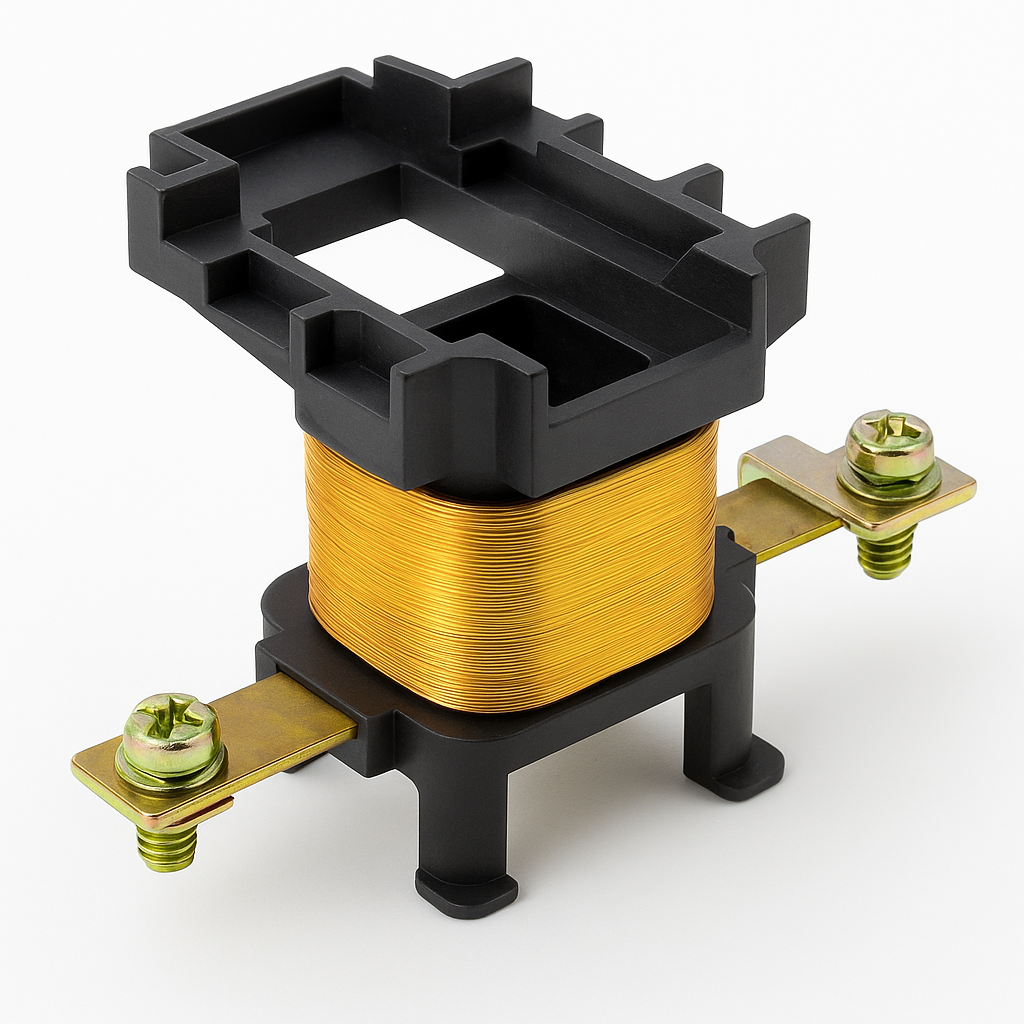

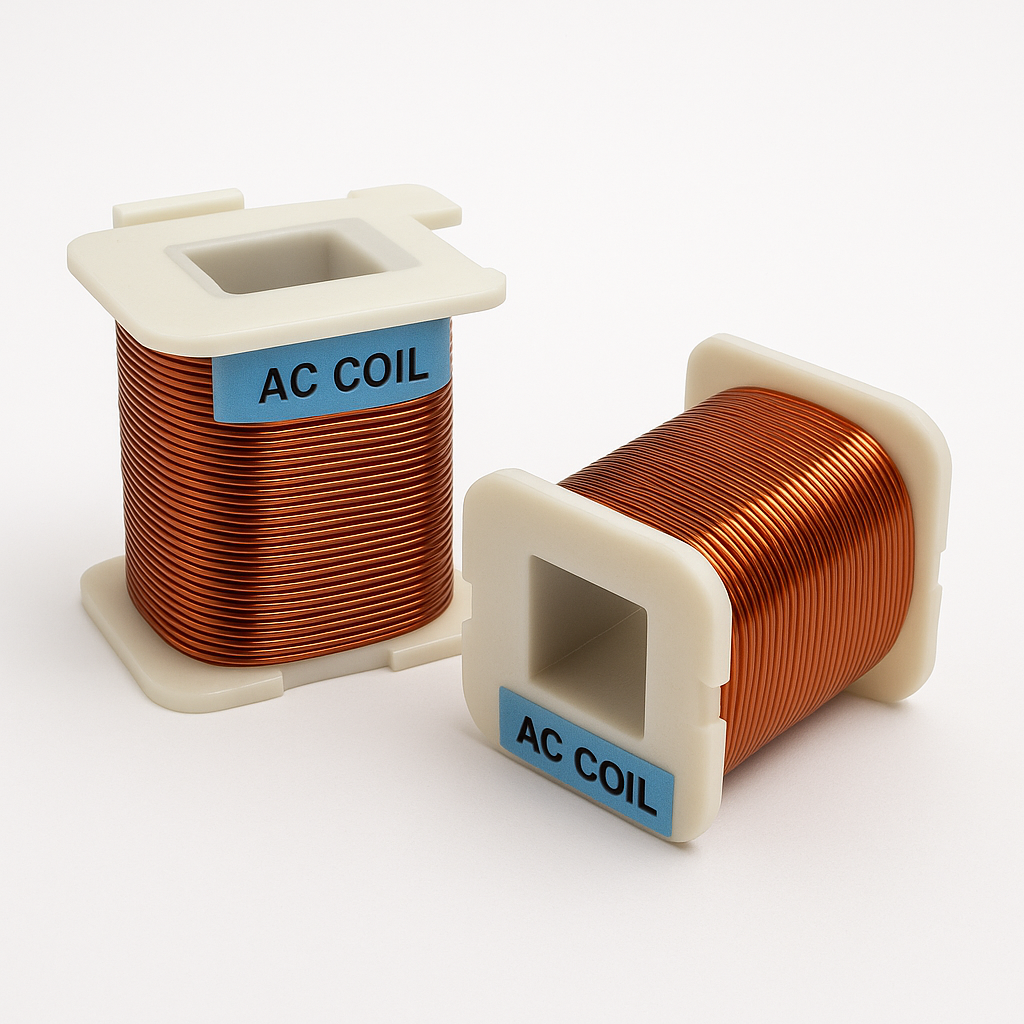

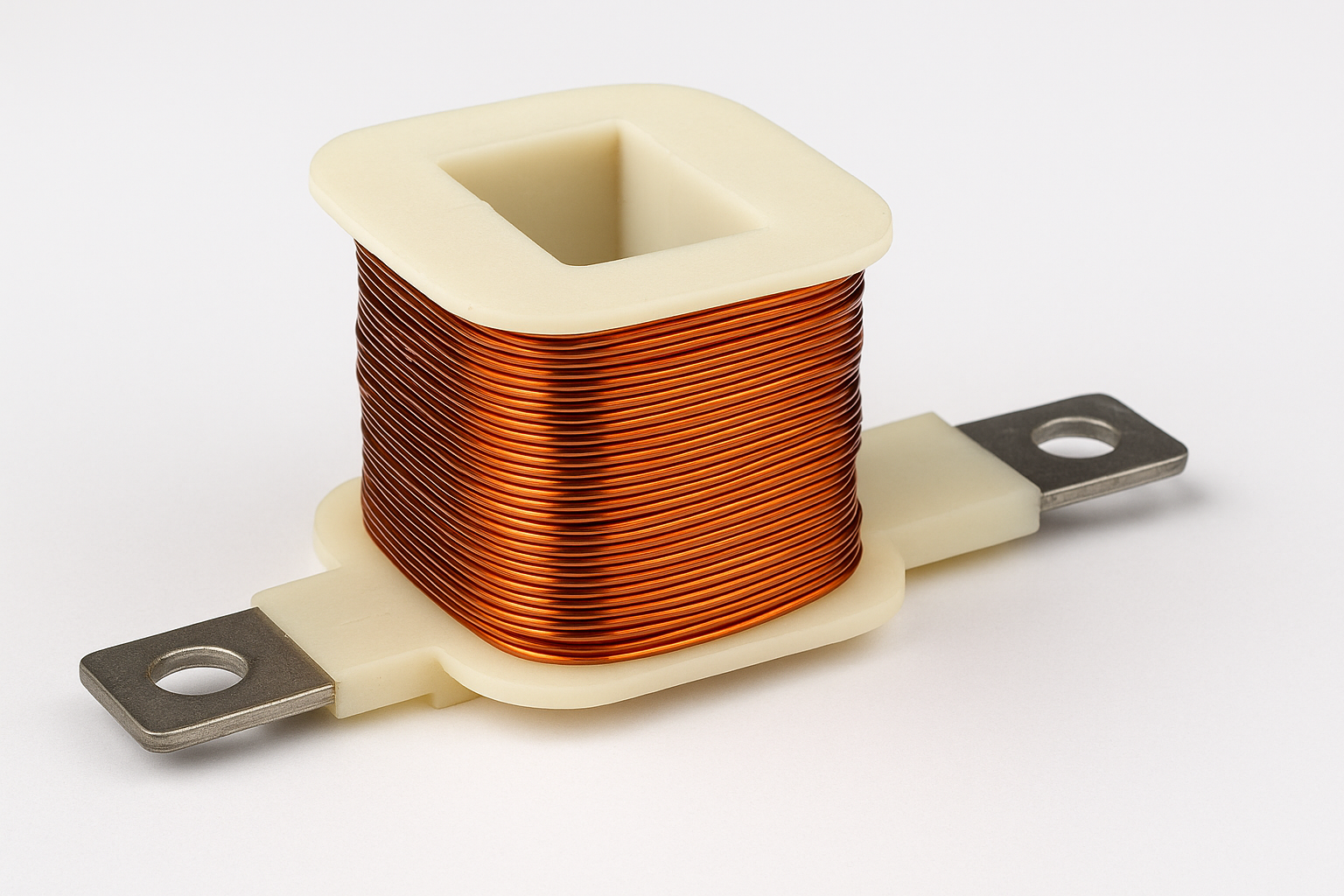

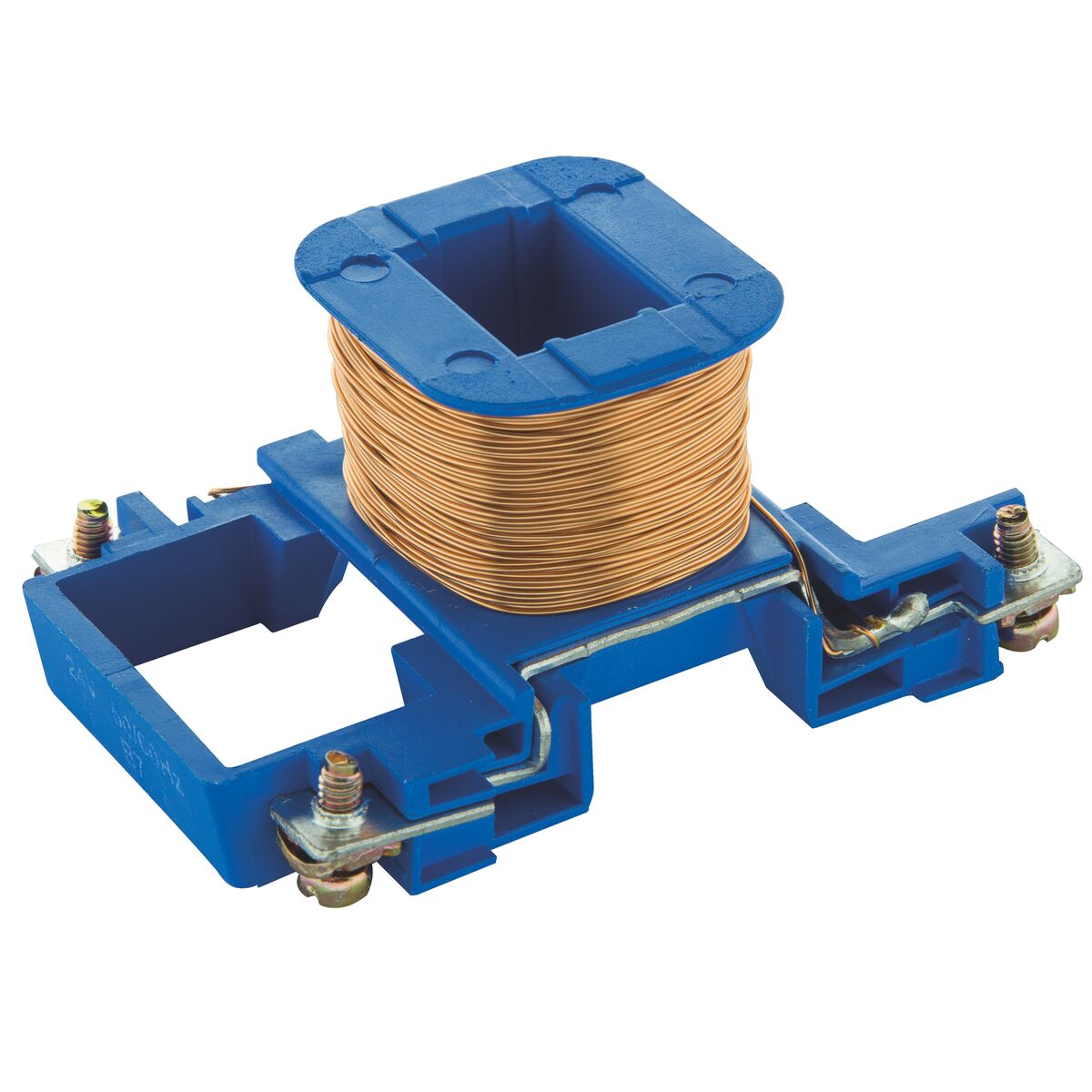

- Contactor coils for motor starters and contactors

- Relay coils and electromagnetic actuator coils

- Solenoid coils for valves and pumps (with spec change)

- Transformer/magnetic coils where similar bobbin geometry applies

Working Video of Machine (How to use & what to look for)

Working Process — Step‑by‑Step

Below is a typical step‑by‑step workflow for 12‑spindle automatic contactor coil winding machine. Depending on your configuration (manual loading vs. automatic loader, optional tap insertion, etc.), some steps are optional.

Pre‑production Setup

- Program selection: Choose the winding program from HMI. Programs store turn counts, layer transitions, direction changes, speed profile, and tension values.

- Tooling installation: Fit the 12 bobbins/formers and secure end‑stops. If custom bobbins are used, change the tooling plate accordingly.

- Wire setup: Load wire spools on servo payoffs. Thread wire through the guides, capstan (if present), and into the winding head. The HMI can run a wire detect routine.

- Tension calibration: Set tension per program. Deptronics machines provide closed‑loop tension monitoring that can be tuned for wire gauge.

- Inspection & pre‑tests: Run an initial dry cycle (no bobbins) to ensure software and hardware motions are correct.

Production Cycle (Typical)

- Start cycle: Operator presses start after loading bobbins into loading fixture.

- Index & secure: Spindles index into position and holders secure the bobbins.

- Traverse & wind: Servo traversal moves across the bobbin width while spindles rotate to lay down wire. For multi‑layer coils, the program controls direction reversal and layer start/stop positions.

- Tension control: Throughout winding, the tension control system maintains consistent tension to avoid loose or overly tight turns.

- Finish & cut: At the programmed number of turns, the machine stops the spindles, secures the wire ends, and cuts the wire automatically.

- Polyster Taping (optional): If specified, the machine can do tape on coils after finish winding operation.

- Unload & pack: Machine removes the finished batch and put into conveyor or bin.

Quality Checks During Process

- Turn count verification: PLC verifies counts via encoder feedback.

- Wire break detection: If wire breaks mid‑cycle, the machine stops and alerts the operator to fix the copper wire and resume.

- Uniformity checks (Optional): Visual or automated measurement systems can be integrated to ensure coil height and layer distribution (optional).

Technical Specifications

| Specification | Details |

|---|---|

| Number of Spindles | 12 / 16 / 20 /24 (customized) |

| Motors | High-precision servo motors |

| Wire Tensioners | Magnetic or optional servo type |

| Spindle Gap | 50.6/61.2/72 mm |

| Max Bobbin Size | 30-50 mm swing |

| Winding Direction | CW / CCW |

| Spindle Stop Accuracy | ±0.1° |

| Copper Wire Range | 0.02–0.60 mm |

| Wire Anchoring Angle | 0° / 90° (motorized also customized) |

| Power Supply | AC 220V, 50Hz |

| Power Consumption | 2.5 kW approx. |

| Air Pressure | 4–6 kg/cm² |

| Optional Devices | Twister, cutter, enamel remover |

| Optional Automation | Auto loading/unloading, taping, clipping, waste wire discharge |

This technical framework ensures that the machine is capable of handling even the most demanding relay applications.

Optional Add‑ons

- Automatic bobbin loader/unloader

- Automatic terminal insertion & forming station

- Automatic soldering / fluxing station

- In‑line testing (LCR, DC resistance, hi‑pot)

- Vision system for visual inspection & coil geometry checks

- Coil tap crimping or welding station

- Dust‑proof / sound reduction enclosure

Key Features

Below are the standout features that make Deptronics’ 12‑spindle contactor coil winding machine a compelling choice.

1. True Parallel Winding with Synchronized Control

All 12 spindles operate in parallel under a single program, synchronized through servo control to ensure identical winding between spindles.

2. High Throughput with Short Cycle Times

With cycle times in the 30–40 second range, the machine dramatically increases parts/hour compared to single‑spindle or manual winding.

3. Closed‑Loop Tension Control

Magnetic tensioner or Servo capstans and tension sensors maintain precise wire tension across all spindles to avoid loose turns, wire damage, or contorted geometry.

4. User‑Friendly HMI & Recipe Management

Operators can change programs, set turn counts, and monitor real‑time diagnostics through a clear touch screen interface. Recipes are stored and recalled easily for different coil types.

5. Modular Design and Custom Tooling

The machine is modular so tooling plates, bobbin holders, and ancillary stations (soldering, crimping, tapping) can be added or modified without a full redesign.

6. Integrated Quality Tests

Built‑in electrical testing stations (LCR, DC resistance) ensure bad parts are removed immediately, improving first pass yield and reducing rework.

7. Safety & Ergonomics

Interlocked safety doors, E‑stop buttons, and well‑placed operator stations reduce the risk of accidents and simplify operation.

8. Low Maintenance & Easy Servicing

Accessible mechanical components, predictive maintenance alerts (if connected), and clear diagnostics reduce downtime.

Advantages

Increased Productivity : By winding 12 coils at once, production output scales linearly with spindle count — a single machine can replace multiple single‑spindle setups.

Consistency & Quality : Computer‑controlled motion and tension eliminate variability from manual winding. This improves electromagnetic consistency, repeatability of inductance, and reduces field failures.

Labor Savings : Automation reduces the number of operators required per shift and diminishes the skill requirement for producing high‑quality coils.

Faster Time‑to‑Market : Program recipes stored on HMI allow quick changeovers between coil types, speeding up prototyping and small batch production with minimal downtime.

Lower Overall Cost of Ownership : Higher throughput, fewer reworks, and predictable maintenance lower the total cost per coil compared to manual or legacy machines.

Scalability :

Modular add‑ons (automatic feeding, tap insertion) allow the production line to scale with demand without replacing the core machine.

Industries That Use This Machine

Automatic contactor coil winding machines are used wherever reliable electromagnetic coils are required. Key industries include:

- Electrical distribution & switching — contactors, relays, and starters used in industrial motor control.

- Automotive & EV components — auxiliary relays, motor control coils, and solenoids.

- HVAC and refrigeration — contactor coils for compressors and fan controls.

- Renewable energy — inverter controls, protective relays, and switchgear.

- Appliances — washing machines, compressors, and heavy appliances requiring motor starters.

- Industrial automation — PLC‑controlled systems, machine actuators, and safety relays.

- Transformers & inductors where bobbin geometry matches contactor coils.

Manufacturers in these sectors benefit from high throughput and consistent coil performance.

ROI Calculation (Detailed Example)

To evaluate ROI, we will calculate a realistic production and cost scenario. ROI depends on local labor rates, electricity, raw material (copper wire cost), machine price, and production hours.

1. High-Speed Production Output

-

Machine winds 12 coils every 30–40 seconds

-

This equals roughly 1,440 coils per hour

Daily Production (10-hour shift):

1,440 × 10 = 14,400 coils per day

Compared to manual winding, this is 10–15× higher productivity.

2. Major Labour Cost Reduction

To produce 14,000+ coils manually, a factory normally needs:

-

8 to 9 workers (depending on skill and consistency)

With the automatic machine:

-

Only 1 operator is required

Monthly Labour Savings:

➡ ₹80,000 to ₹1,50,000/month

3. Dramatically Lower Rejections

-

Manual winding rejection: 3%–8%

-

Automatic winding rejection: below 1%

This reduction in scrap and rework saves:

➡ ₹20,000 to ₹40,000/month

4. Combined Monthly Savings

Labour + rejection savings =

➡ ₹1,00,000 to ₹1,50,000 per month

(Depending on shifts and workload)

5. Payback Period (ROI)

With these savings, the machine investment is recovered in:

➡ 8–12 months

In factories running two or three shifts, ROI can be even faster — often 5–7 months.

ROI Summary and Notes

- ROI is highly sensitive to utilization (uptime), selling price, and materials cost.

- Many customers reach payback within months when the machine is integrated into a continuous production plan that supplies multiple customers.

- Additional revenue streams such as value‑added operations (pre‑soldering, tap forming) further increase margins.

- Deptronics can help tune the machine for optimal cycle time for your specific coil geometry and wire gauge, increasing throughput.

Installation & After‑Sales Support

A successful machine deployment extends beyond delivery. Deptronics provides structured installation, training, and support to ensure you reach full production quickly.

Pre‑Delivery Activities :

Before dispatching the machine, Deptronics ensures full transparency and smooth preparation for installation. Our pre-delivery process includes:

1. Sharing Machine Photos & Videos : We send clear pictures and running videos of the machine to the customer for approval before dispatch.

2. Live Video Call Demonstration : Customers can join a live video call to see the machine running in real production mode and verify all functions.

3. Optional Factory Visit (China) : If required, customers may visit our partner factory in China for physical inspection and testing of the machine before shipment.

4. Machine Dimensions Provided in Advance : We share complete machine dimensions and layout drawings, so the customer can prepare the workplace and ensure enough space for installation and operator movement.

5. Installation Requirements Checklist : We provide a simple list of what is required at the customer’s site for smooth installation, such as:

- Dust-free working environment or enclosed cabin

- Stable air pressure supply (6 bar)

- UPS-based or stable power source

- Proper earthing

- Adequate lighting and access for maintenance

Installation & Commissioning

- On‑site installation: Machine delivered and assembled at customer site.

- Electrical & pneumatic hookups: Verified by Deptronics engineers.

- Commissioning run: Production runs performed to demonstrate cycle times and yield.

- Acceptance test: Customer signs off after validated production results.

Training

- Operator training: Hands‑on training for up to 2–4 operators covering program selection, tooling changeover, and basic troubleshooting.

- Maintenance training: Training for in‑house maintenance staff on scheduled servicing, lubrication points, and parts replacement.

After‑Sales Support

- Standard warranty: 12 months from commissioning (parts & labor terms listed in the quotation).

- Spare parts supply: Deptronics supplies critical spare parts and recommended spare kits for fast replacement.

- Remote support: Diagnostics can be supported remotely via video calls whenever customer required.

- Annual maintenance contracts (AMC): Available to keep machines at peak performance, including scheduled visits, calibration checks, and software updates.

- Upgrades: Software or hardware upgrades can be provided when new features or performance enhancements are available.

Spare Parts & Consumables

- Wear items: Cutting blades, capstan pads, guides, felts, cutter, pneumatic cylinder and sensors.

- Critical spares: Servo motors, encoders, PLC modules, and optical sensors.

- Recommended spare kit: Deptronics recommends a 3–6 month spare kit depending on production volume.

Why Choose Deptronics as Your Technology Partner

Deptronics Technologies is positioned as a specialist in coil winding and production line automation for Indian manufacturers. When choosing a technology partner, several factors set Deptronics apart:

Domain Expertise : With years of experience supplying coil winding equipment and production lines, Deptronics understands electromagnetic product requirements across transformer, contactor, relay, and solenoid markets.

Customization Capability : Deptronics customizes tooling, software, and integration points to match customer bobbin geometries and production workflows. This reduces changeover times and speeds time‑to‑production.

Local Presence & Support : Based in India, Deptronics provides local commissioning, spare parts, and service resources — eliminating long lead times for support that international vendors may have.

Channel Partner of OEM Manufacturer : Deptronics is the channel partner of so reputed machine manufcaturer company of china to provide engineered solutions that combine international design with local service.

Training & Documentation : Deptronics delivers thorough operator and maintenance training, checklists, and documentation so your team can manage the machine independently.

Proven ROI & Case Studies : Deptronics machines have delivered high throughput and fast payback for multiple clients. Customers report reduced manual reworks, improved coil uniformity, and simplified production planning.

End‑to‑End Solutions : Beyond a single machine, Deptronics can supply downstream processes (soldering, testing, packing) and help design a full production line for contactor coil manufacturing.

Final Thoughts

Investing in a Deptronics 12‑spindle automatic contactor coil winding machine transforms coil manufacturing from manual, inconsistent processes into a predictable, high‑volume, and quality‑driven operation. With parallel winding, servo control, and modular add‑ons, you can scale production while keeping costs under control.

When evaluating a purchase, consider not just the machine price but the production model: how many hours per day will the machine run, the selling price of finished coils, and the expected yield. With reasonable utilization and market demand, the machine often pays back within months and becomes a long‑term asset for consistent revenue and market expansion.

Deptronics Technologies combines localized support, domain knowledge, and production automation expertise to ensure your machine meets specifications and continues to perform.

Contact Us

For machine inquiries, pricing, or customization options, contact us today!

DEPTRONICS TECHNOLOGIES

📌 Contact Person: Deepanshu Saxena

📞 WhatsApp/ Mobile: +91-8800622761

🌐 Website: https://coilwinder.in/

📧 Email: [email protected]

For mass production of relay coils, check our “Automatic Production Line for Mass Manufacturing of Relay Coils”

Sidhartha Shukla –

They have very deep knowledge of machines, and also they trained our people very well during installation.