Overview of the 20-Spindle Winding Machine Line

The 20-spindle automatic winding line is a next-generation solution engineered for ultra-high output and reliability.

It integrates every essential stage of inductor or transformer production — including auto bobbin feeding, loading, copper wire winding, taping (optional), flux dipping, solder dipping, and unloading — into one seamless automation flow.

Each spindle is individually controlled for synchronized operation, ensuring all 20 coils are wound simultaneously with consistent precision.

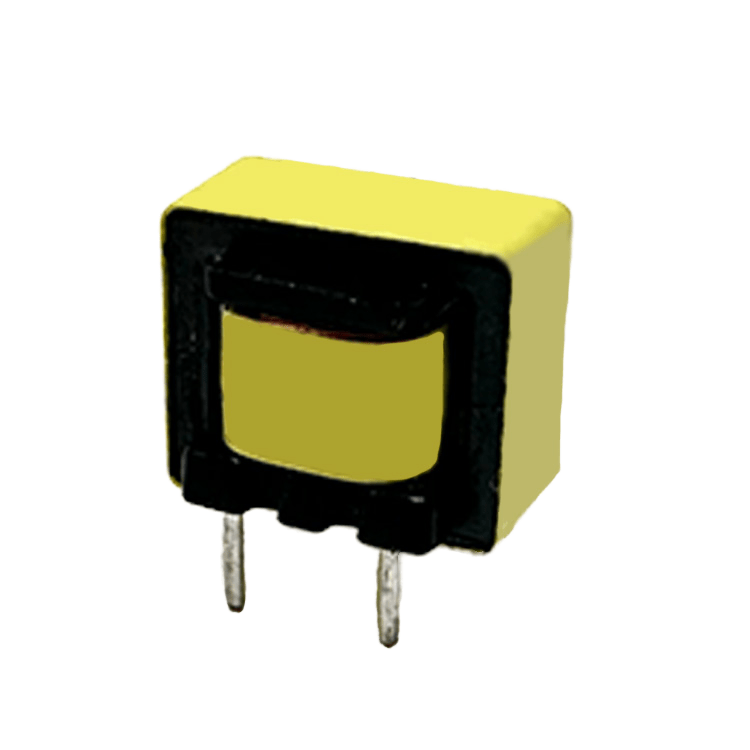

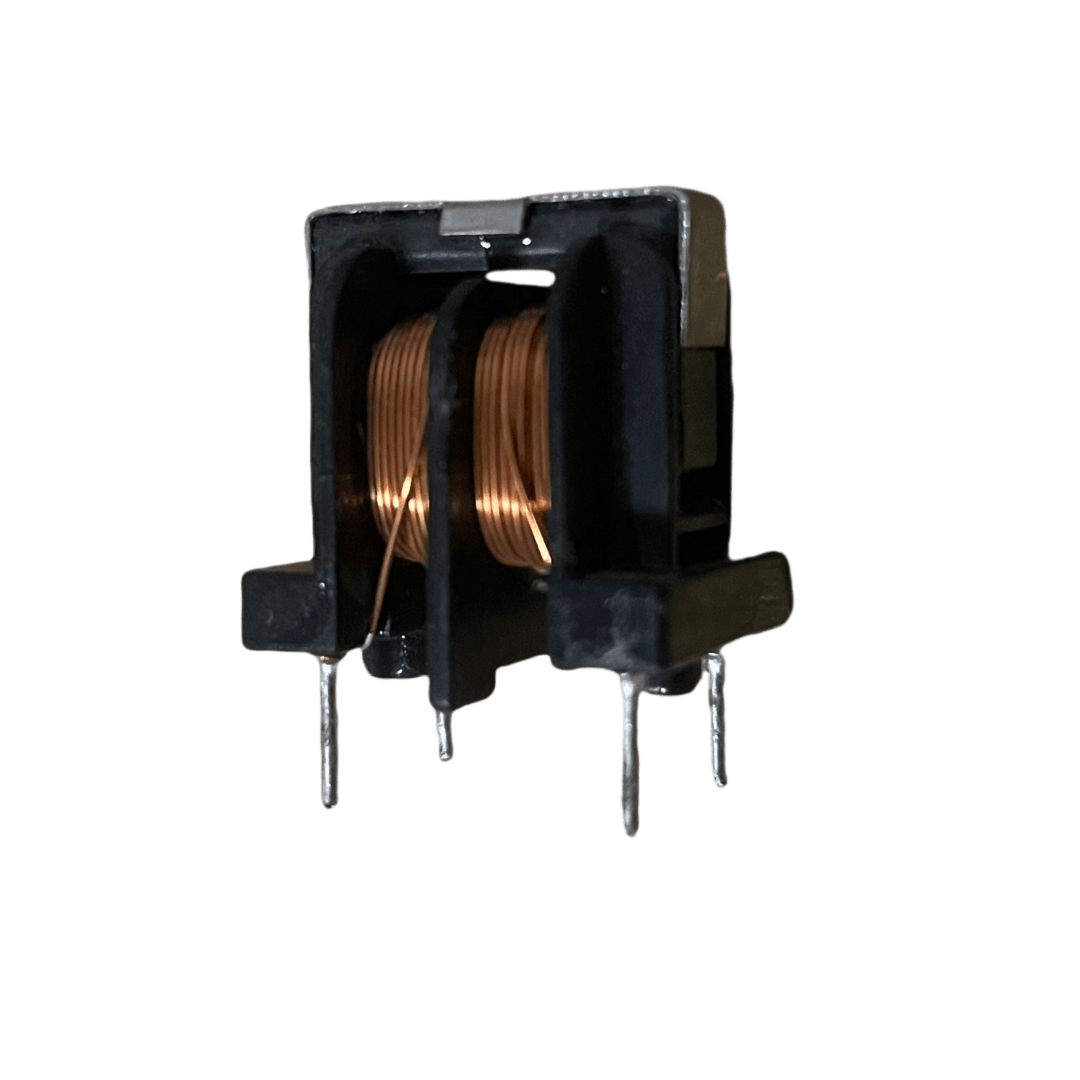

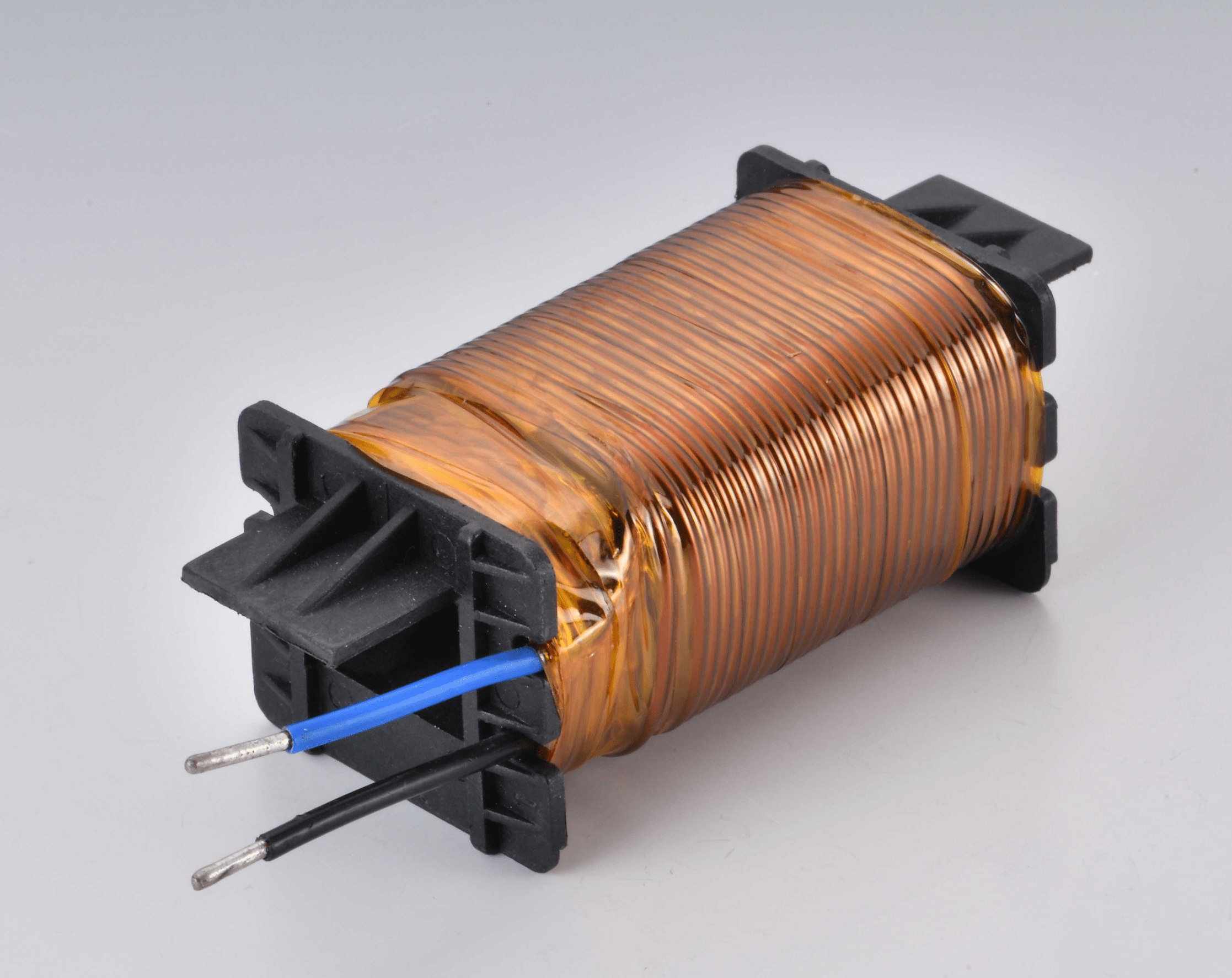

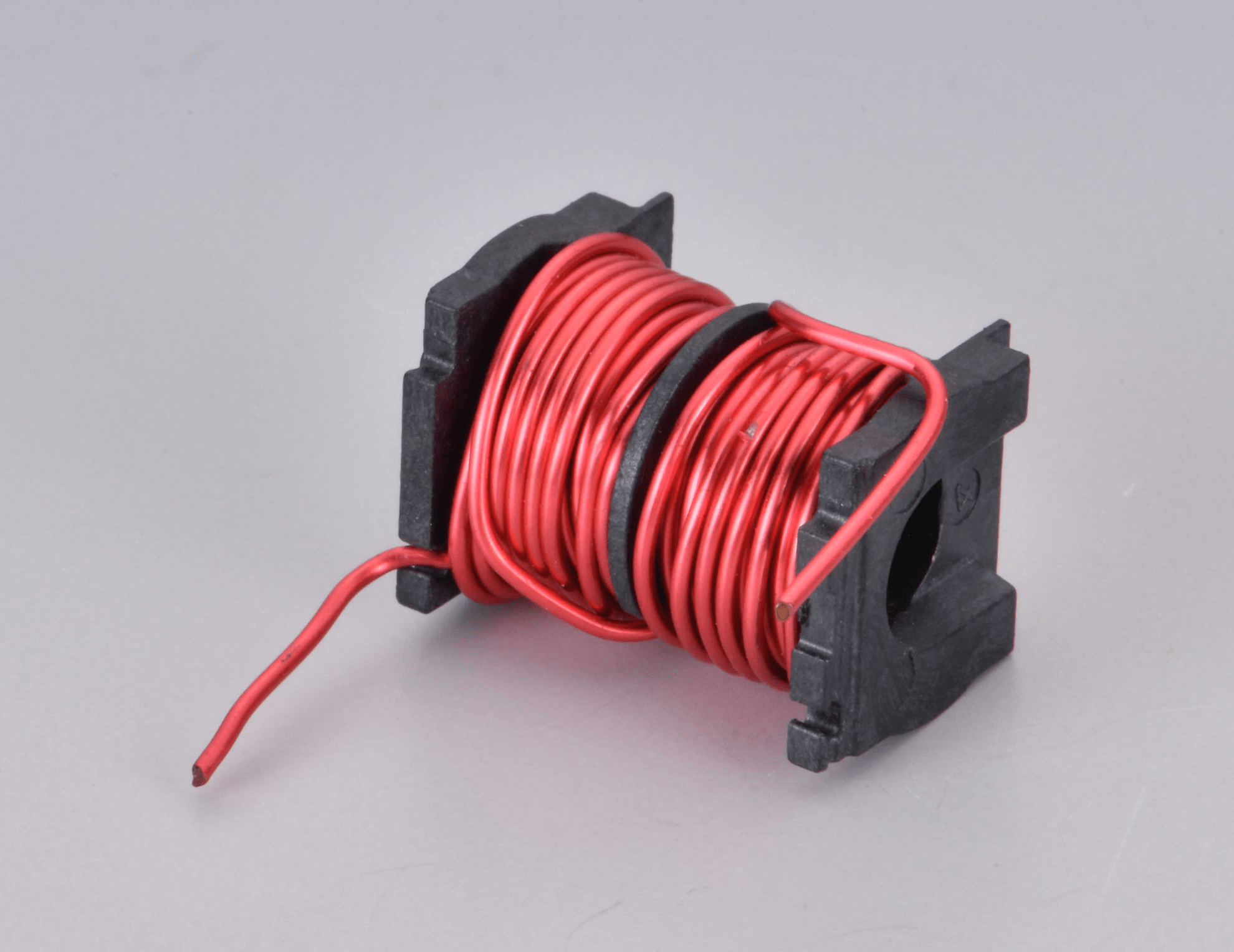

This machine is ideal for manufacturers handling large volumes of SMPS transformers, ferrite inductors, EE/EFD/PQ cores, and similar products where efficiency and repeatability are key to business success.

Key Highlights

20 Spindle Simultaneous Winding — High-speed multi-spindle system for mass coil production.

Automatic Bobbin Feeding & Loading — Vibrator bowl with auto orientation, no manual handling required.

Auto Unloading to Soldering Station — Robotic transfer for clean and efficient operation.

Auto Flux & Solder Dip — Uniform solder quality across all coil terminals.

Optional Taping Unit — Add taping process post-winding for insulation if required.

Integrated Control System — PLC + HMI-based interface for easy parameter setup and monitoring.

High Accuracy & Repeatability — Ensures identical output across all spindles.

Compact, Modular Design — Occupies minimal floor space for factory efficiency.

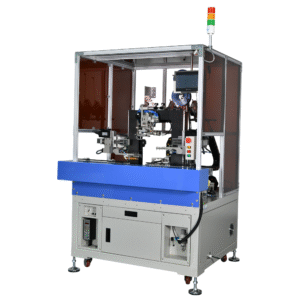

Machine Structure & Design

The 20-Spindle Automatic Winding Line is built with robust mechanical construction, ensuring durability and stability during long production cycles. The base frame is made from high-quality steel for vibration-free operation. Each spindle assembly uses servo motors for independent control of winding speed and pitch.

Key components include:

- Vibrator bowl feeder for automatic bobbin feeding

- Pick & place robotic loader

- Main 20-spindle winding machine

- Auto unloading system

- Dual soldering station (flux + solder)

- Optional taping and testing units

The layout can be customized based on client requirements, ensuring seamless integration into existing factory lines.

Technical Specifications

| Parameter | Specification |

|---|---|

| Number of Spindles | 20 |

| Wire Diameter | 0.05 mm to 0.35 mm (customizable) |

| Bobbin Size Compatibility | EE10 – EE25 / PQ20 – PQ32 / UU10.5 and similar |

| Winding Speed | Up to 2000 RPM per spindle |

| Winding Type | Single / Bifilar / Multi-layer programmable |

| Control System | PLC with Touchscreen HMI |

| Drive System | Precision Servo Motors |

| Bobbin Feeding | Automatic via Vibrator Bowl |

| Loading & Unloading | Pneumatic / Robotic |

| Soldering | Automatic Dual Bath (Flux + Solder) |

| Air Supply | 0.4–0.6 MPa |

| Power Supply | AC 230V / 50Hz |

| Dimension | Custom as per line configuration |

| Optional Add-ons | Auto taping, core insertion, auto testing, vision inspection |

Machine Working Process

Step 1: Automatic Bobbin Feeding

The process starts with an automatic vibrator bowl feeder that continuously supplies bobbins to the system. Each bobbin is aligned and oriented correctly before entering the loading section.

Step 2: Auto Bobbin Loading

Using pneumatic or robotic pick-and-place mechanisms, each bobbin is loaded into the winding fixture precisely. The machine ensures exact positioning to maintain accuracy during high-speed winding.

Step 3: High-Speed 20-Spindle Winding

All 20 spindles operate simultaneously, winding copper wire according to the programmed number of turns and pattern.

Each spindle is servo-controlled, allowing independent speed adjustment, pitch control, and tension monitoring.

Step 4: Optional Auto Taping

If the product requires insulation taping after winding, the optional auto taping module can be added. This ensures each coil is wrapped with consistent tape tension and overlap.

Step 5: Auto Unload & Transfer

After winding, the machine automatically unloads finished coils from the spindle fixture and transfers them to the next stage (soldering station).

Step 6: Auto Flux Dip & Auto Solder Dip

The coils pass through an automated dual-dipping system — first in flux, then in molten solder.

This ensures clean, durable, and reliable solder joints with precise dipping depth and timing control.

Step 7: Optional Core Assembly & Testing

Post-soldering, additional automation modules can perform ferrite core insertion, taping, and electrical testing (LCR measurement). These add-ons transform the machine into a complete inductor production line.

Step 8: Final Unloading

The finished coils are automatically placed in collection trays, ready for packing or further assembly.

Working Machine Videos :

Advantages & ROI (Return on Investment)

A. Productivity Advantages

- 20 coils per cycle instead of 1 — 20x faster output

- Fully automatic line — No operator dependency

- Continuous operation with minimum downtime

- Stable and uniform winding quality

B. Cost Advantages

- Reduced labor cost by up to 80%

- Consistent quality reduces rework and rejection rates

- Faster production = quick ROI (usually within 8–12 months)

C. Technical Advantages

- High-speed servo control system

- PLC-based programmable operation

- Adaptable to multiple bobbin sizes

- Easy integration with future automation stages

Industry Applications

This 20-spindle machine line is suitable for:

- SMPS Transformers

- Ferrite Inductors

- Power Chokes

- Adapters and Chargers

- LED Drivers

- Communication Transformers

- Miniature High-Frequency Transformers

Any industry requiring mass, consistent, and high-quality winding output can benefit from this system.

After-Sales Service & Technical Support

Deptronics Technologies provides complete support across India — ensuring customers enjoy smooth and worry-free machine operation.

Our services include:

- Installation and Commissioning

- On-site Training for Operators & Engineers

- Remote Technical Assistance

- Preventive Maintenance Support

- Warranty & Spare Parts Availability

We believe in long-term partnerships, and our experienced team ensures that every customer achieves maximum uptime and productivity from their automation investment.

Why Choose Deptronics Technologies

- Strong expertise in coil winding, soldering, and production line automation.

- Proven installations in leading transformer and inductor factories in India

- Quick local response and after-sales service.

- Tailor-made solutions for every client’s product and production requirement.

With Deptronics Technologies, you don’t just buy a machine — you gain a complete automation partner dedicated to your success.

Contact Us

The Automatic 20-Spindle Inductor Bobbin Coil Winding Machine is the ultimate solution for companies aiming for mass coil production with precision and efficiency.

By integrating auto feeding, high-speed winding, auto soldering, and optional core assembly, it replaces multiple manual operations with a single, smart, fully automated line.

As electronics manufacturing continues to evolve, automation is no longer a luxury — it’s a necessity.

With Deptronics Technologies, you can stay ahead of the curve with machines that deliver speed, stability, and superior performance.

Whether you are manufacturing inductors, transformers, or ferrite coils, this production line is your path to consistent quality, reduced cost, and higher profitability.

For machine inquiries, pricing, or customization options, contact Deptronics Technologies today!

DEPTRONICS TECHNOLOGIES

📌 Contact Person: Deepanshu Saxena

📞 WhatsApp/ Mobile: +91-8800622761

🌐 Website: https://coilwinder.in/

📧 Email: [email protected]

Reviews

There are no reviews yet.