General features:

1. Coil Winding Section:

- Winding Speed: 500–12000 RPM (revolutions per minute), adjustable depending on coil size and material.

- Wire Diameter: Supports a range from 0.1 mm to 2.0 mm, depending on the relay design.

- Coil Turns: Programmable from 50 to 4000+ turns per coil, customizable based on product specifications.

- Coil Inner Diameter: Typically 4 mm to 50 mm, adjustable for different relay designs.

- Coil Outer Diameter: Ranges from 10 mm to 70 mm, customizable for varied designs.

- Wire Tension Control: Automatic wire tensioning system with a range of 10-500 grams, ensuring uniform winding.

- Wire Spool Capacity: Typically supports spools weighing up to 10-20 kg.

- Coil Forming: Automatic coil alignment and formation with adjustable forming parameters.

2. Soldering Section:

- Soldering Type:

- Dip Soldering: For bulk soldering of terminals.

- Selective Soldering: For precise soldering of specific components, such as terminals on leads.

- Laser Soldering: High precision soldering for delicate or complex designs.

- Soldering Temperature: Adjustable from 220°C to 550°C, depending on the soldering method and material requirements.

- Soldering Time Control: Precise control over soldering duration to ensure optimal joint quality.

- Soldering Speed: Up to 10-20 units per minute, based on component size and complexity.

- Flux Management: Automatic flux application and cleaning system for high-quality solder joints.

3. Automation & Control:

- PLC (Programmable Logic Controller): Central control unit for managing winding, soldering, and overall machine functions.

- Human-Machine Interface (HMI): Touchscreen interface for easy operation and programming, offering user-friendly control of settings.

- Adjustable Parameters: Users can modify winding turns, soldering temperature, and other machine settings through the interface.

- Sensor Integration: Advanced sensors for position detection, wire tension control, and quality assurance.

- Automatic Fault Detection: Real-time monitoring and fault diagnosis, with alerts to prevent production downtime.

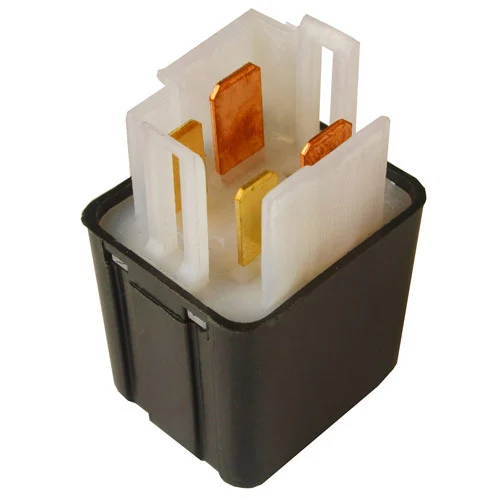

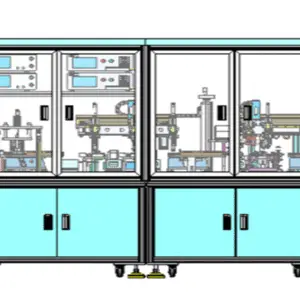

Vehicle Self Starter Relay Automatic Production Line Coil Winding Soldering Machine

4. Production Capacity:

- Output Rate: Typically 500 to 5000 units per day (depending on the complexity of the relay and automation level).

- Cycle Time: Approximately 1 to 3 minutes per unit, depending on design and machine speed settings.

- Production Flexibility: Can handle different relay designs and sizes with easy changeover procedures.

5. Power and Utilities:

- Power Supply: 230V/50Hz, 1-phase (can vary based on location and machine design).

- Power Consumption: Typically 5–15 kW, depending on the machine’s size and functionality.

- Air Supply: 0.4-0.6 MPa (compressed air required for various functions such as automation and soldering processes).

- Cooling System: Integrated cooling system for soldering components, maintaining consistent performance.

6. Safety Features:

- Emergency Stop: Emergency stop buttons at multiple points around the machine for immediate shutdown in case of issues.

- Safety Guards: Enclosed working area with safety interlocks to prevent accidents during operation.

- Overload Protection: Built-in overload protection to prevent motor and electrical damage.

7. Dimensions & Weight:

- Machine Size: 2000 mm x 1000 mm x 1800 mm (approximate, varies by model).

- Weight: Typically ranges from 1000 kg to 4000 kg, depending on the design and configuration.

8. Additional Features:

- Automatic Component Feeding: For terminals and wire components to reduce manual labor.

- Product Quality Control: Automatic testing for electrical parameters like resistance and inductance.

- Cleaning System: Automatic cleaning system for removing flux residue from solder joints.

- Data Logging: Machine logs production data for quality tracking and process optimization.

| Feature | Description |

|---|---|

| Revolutionary Automation | Experience cutting-edge automation designed to streamline the production of high-performance starter relays. |

| Precision Coil Winding | Achieve flawless coil windings with programmable turns, tension, and speed for optimal performance. |

| Advanced Soldering Technology | Utilize selective, dip, or laser soldering for perfect electrical connections and reliable joint integrity. |

| High-Speed Production | Boost efficiency with a rapid production rate of up to 2000 units per day, without compromising quality. |

| User-Friendly Control | Easy-to-use HMI with intuitive controls, enabling quick setup and seamless operation throughout production. |

| Unmatched Quality Control | Automatic testing, visual inspection, and data logging ensure every relay meets stringent quality standards. |

| Energy Efficient | Designed with energy-saving features to reduce power consumption while maintaining high output levels. |

| Safety First | Equipped with multiple safety features, including emergency stops and protective guards, for safe operation. |

| Flexible & Customizable | Adapt to various relay designs with fast changeovers and customizable parameters for different products. |

| Future-Proof Manufacturing | Integrates with modern automation systems, ensuring scalability and future growth for your production line. |

More details, please contact freely :

DEPTRONICS TECHNOLOGIES

Contact : Deepanshu Saxena

Mobile : +91-8800622761

WhatsApp : https://wa.me/918800622761

Email : [email protected]

Reviews

There are no reviews yet.