Key features of an SMPS transformer coil winding machine :

- Automatic Winding: The machine can automatically wind copper wire around a bobbin, ensuring uniformity in the number of turns and winding patterns.

- Precision Control: The machine allows for precise control over the winding parameters such as tension, speed, and layer count. This is critical for achieving the desired electrical characteristics of the transformer in manual winding process.

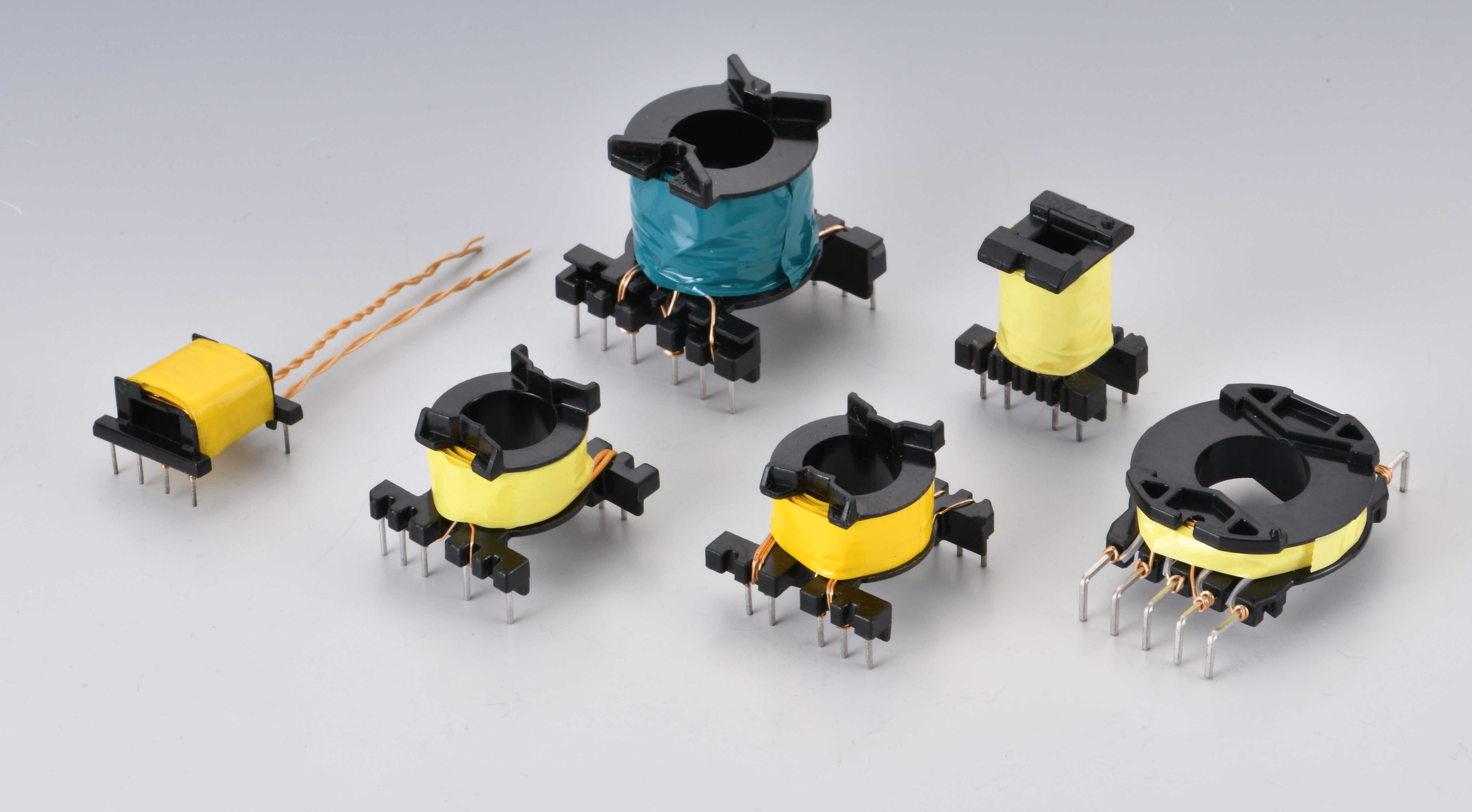

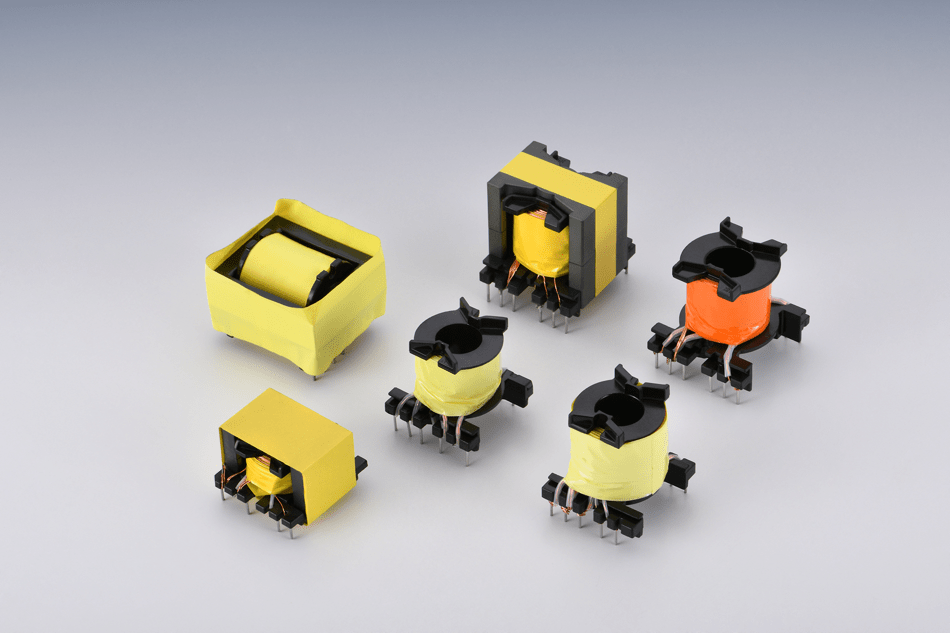

- Coil Winding Patterns: It can accommodate different winding patterns such as bifilar or trifilar windings along with insulation sleeve tube & margin tapes, which are commonly used in SMPS transformers.

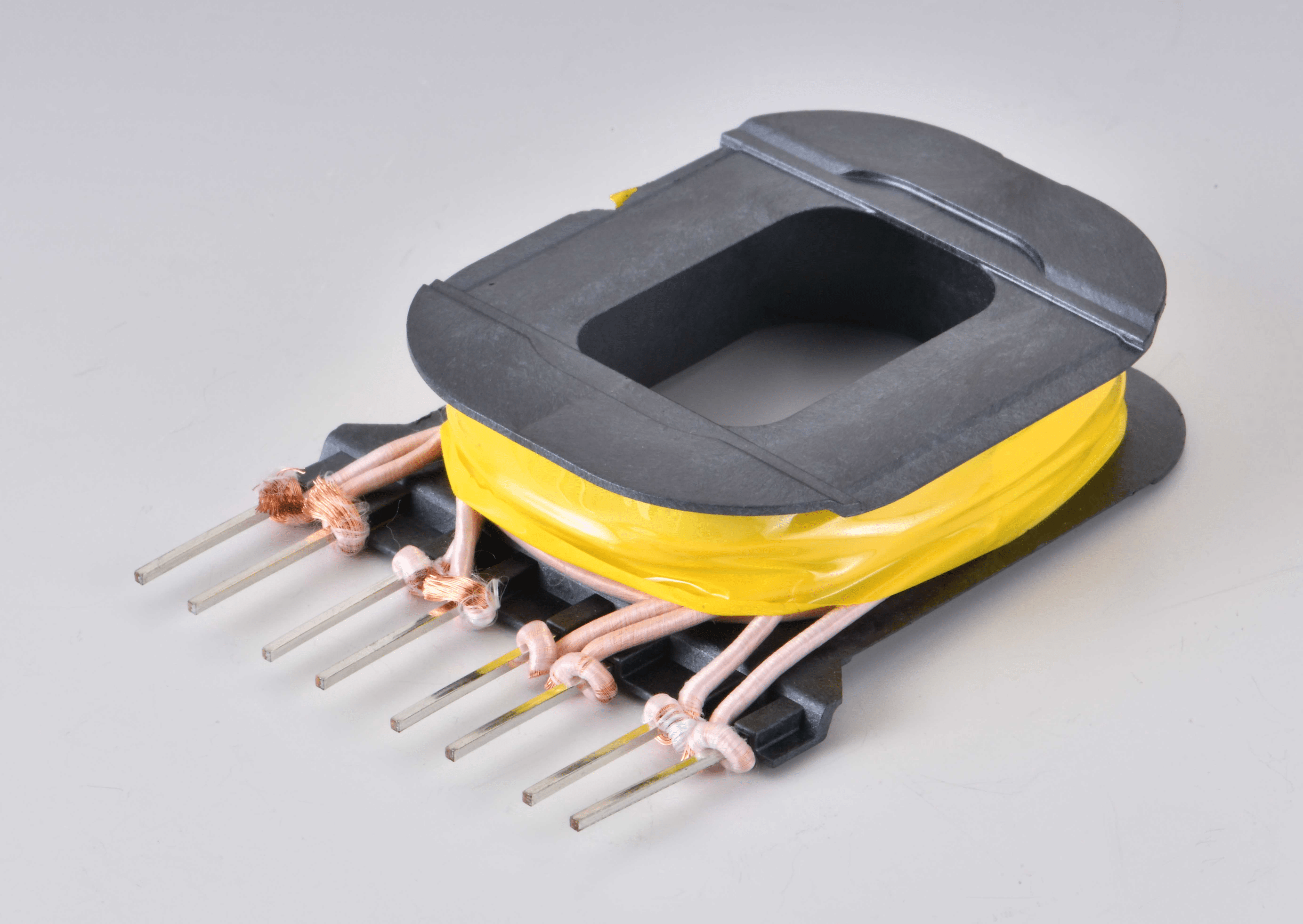

- Insulation Sleeve & Margin Tape : These machines are very suitable for winding applications where insulation sleeve & margin tapes required with winding process, as most high voltage smps transformers required sleeve insertion for safety and better performance.

- High Efficiency: SMPS transformers need to handle high-frequency switching, and the winding machine ensures that the transformer is wound in a way that minimizes losses and optimizes performance.

- Multi-stage Winding: In some cases, these machines can handle multi-stage winding processes, which involve winding multiple coils for primary and secondary windings on the same bobbin.

- Customization: Machines may be customizable to meet the specific needs of different SMPS transformer designs, including different bobbin sizes, wire gauges, and winding configurations.

Working Videos :

Applications:

- SMPS Transformers: Winding machines are primarily used in the production of transformers for switched-mode power supplies in various electronic equipment such as power adapters, computers, and mobile phones.

- High-Frequency Transformers: These machines are also used for winding transformers used in high-frequency applications, such as in RF (radio frequency) transformers.

Functions of the Machine:

- Single Arm Design:

- The “single-arm” refers to the winding machine having a single set of winding spindles or arms, typically used for winding one coil at a time. This setup is simple and efficient for high frequency, smaller transformer designs like EE, EFD, ETD, PQ model transformer coil winding.

- This design reduces complexity and space requirements while ensuring precise winding operations.

- 3-Wire Configuration:

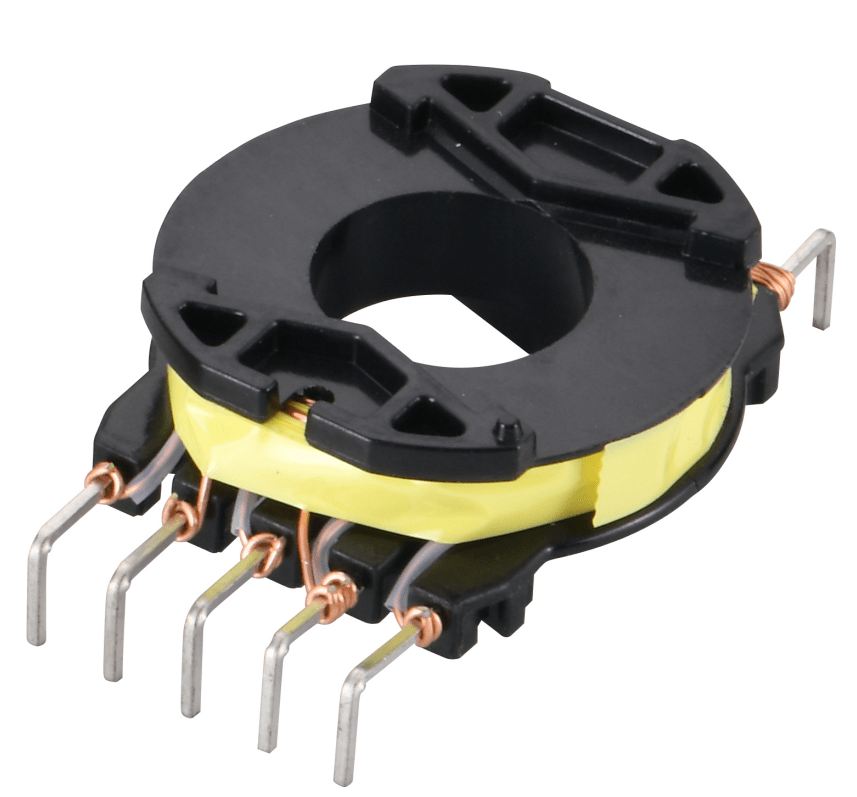

- 3-wire winding typically refers to the machine’s ability to wind three separate conductors simultaneously. This is common for transformers requiring multiple outputs or windings.

- It can be used to wind a primary coil and two secondary windings on a single transformer, all in a single winding process.

- 3-Sleeve Configuration:

- The “3-sleeve” designation refers to the use of three separate sleeves or sections to wind the coils. This could mean that the transformer has three separate winding zones, with each zone wrapped in a separate sleeve or insulation material.

- This design helps in optimizing the performance of the transformer by ensuring that each coil or winding is properly insulated and organized, reducing cross-talk and interference.

Advantages:

- Efficiency: The machine is designed to improve winding efficiency by winding multiple wires and coils simultaneously, reducing the overall winding time.

- Precision: It offers high precision and consistency in the winding process, crucial for achieving the required electrical characteristics of SMPS transformers.

- Space Saving: By winding multiple coils with one machine, it minimizes the need for additional winding machines, saving space in the production area.

- Automated Process: The winding machine typically features automation features such as tension control, wire feeding, and layering, which ensures uniformity in the coils and reduces manual errors.

More details, please contact freely :

DEPTRONICS TECHNOLOGIES

Contact : Deepanshu Saxena

Mobile : +91-8800622761

WhatsApp : https://wa.me/918800622761

Email : [email protected]

Bharat Thakur –

Best quality machines I have ever seen 👍