What Is an Inductor Coil Winding Machine?

An Automatic Ferrite Inductor Coil Winding Machine is a high-speed production system that winds copper wire onto ferrite bobbins with precision and consistency. Unlike manual or semi-automatic machines, this model handles:

- Bobbin loading

- Precise winding

- Wire tension control

- Wire cutting

- Optional taping

- Optional twisting

- Automatic unloading

all within a single automatic cycle.

The purpose of this machine is to increase output, maintain uniformity, reduce rejection rates, and simplify the production process for electronics manufacturers.

Machine Design & Construction

Automatic Inductor Coil Winding Machine is built on a strong mechanical frame with a modular layout. It includes components such as:

- 12 servo-driven spindles

- Automatic bobbin loading system

- Servo-controlled X/Y wire guide movement

- Precision wire tension assembly

- Optional Pneumatic nipper cutters

- Optional taping unit

- Optional twisting unit

- HMI touch panel

- Advanced motion controller

- Industrial-grade pneumatics

The machine structure is made using a rigid steel body to avoid vibration and achieve stable operation even during high-speed winding.

Working Video

Key Features

12/16/20/24 -Spindle High-Productivity Winding System

The central feature of this machine is its 12 winding spindles, allowing 12 inductors to be produced simultaneously. Each spindle is controlled with programmable servo motors for:

- Accurate winding turns

- Smooth rotation

- Controlled acceleration/deceleration

- Repeatable output

The spindles maintain uniform speed, ensuring tight tolerance even in high-frequency inductors.

Automatic Bobbin Loading

Instead of manually fixing bobbins one-by-one, the operator simply places blank bobbins in a loading tray.

The machine’s loading mechanism automatically:

- Picks bobbins from the tray

- Positions them correctly

- Places them onto the winding spindles

This reduces operator workload and increases speed.

Servo-Controlled Wire Guide

The wire guide moves along programmed distances for:

- Layer arrangement

- Cross-layer positioning

- Multiple passes

- Step winding

- Final lead positioning

Servo movement ensures:

- No enamel damage

- No misalignment

- Exact turn distribution

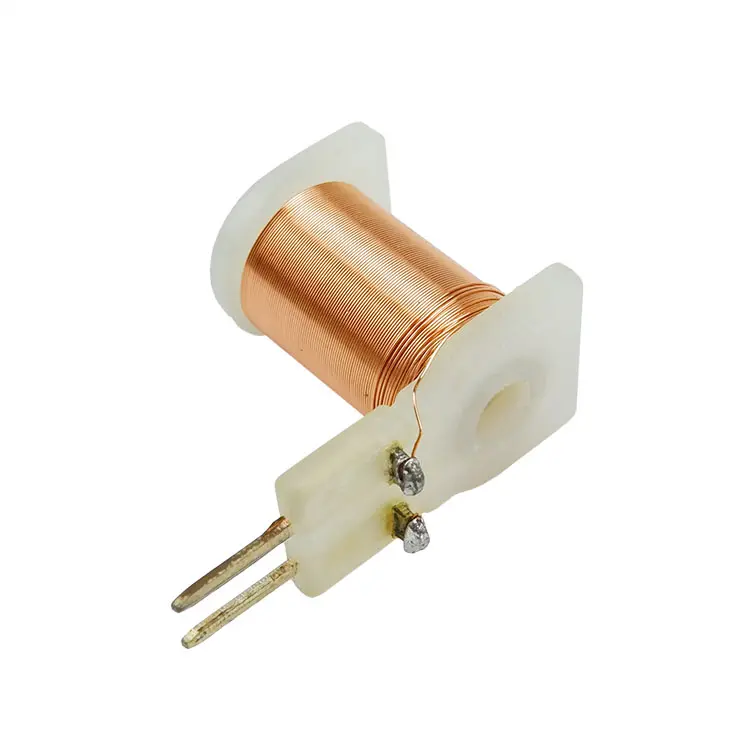

Intelligent Wire Tension System

Wire tension directly affects inductance value and resistance.

This machine uses:

- Magnetic tension control

- Spring-loaded tension arms

- Constant-torque settings

This ensures uniform wire tension across all 12 coils.

Optional Pneumatic Nipper Scissors

The machine uses high-speed pneumatic cutters for:

- Start wire cutting

- End wire cutting

- Heavy gauge wire cutting for vertical bobbins

The cutting mechanism is synchronized with the winding process to ensure clean and accurate wire trimming.

Optional Taping Unit

If insulation tape is needed around the inductor, an optional taping unit can be attached. This provides:

- Uniform taping

- Controlled tape pressure

- Perfect finishing

Useful for EE & UU series coils that require insulation for SMPS applications.

Optional Copper wire Twister Unit

Twisting prevents fine wire breakage and enhances flexibility.

This optional unit is useful for:

- Very fine wires (0.05–0.1 mm)

- High-frequency coils

- Sensitive bobbins that require multiple layers

Smart Touch HMI-Based Programming

The operator can program:

- Winding turns

- Speed

- Wire guide travel (X,Y,Z,S axis movements)

- Tension levels

- Start and end points

- Layer count

- Dwell time

- Cutting sequence

Multiple winding programs can be stored for different inductor models.

Automatic Unloading

After winding, the machine automatically ejects finished coils into the unloading tray.

The operator does not need to manually remove each bobbin from spindle mandrel tools.

Safety and Interlocks

The machine includes:

- Overload protection

- Wire break detection

- Emergency stop

- Pneumatic interlocks

- Door sensors (optional)

Working Principle – Step-by-Step Operation

Bobbin Loading : Operator places a batch of blank bobbins into the loading tray.

Automatic Bobbin Transfer : Machine automatically transfers bobbins from the tray and mounts them onto spindles.

Winding Preparation : Wire guide moves to the starting position.

Tensioner engages.

Program activates.

Winding Cycle Begins

All 12 spindles rotate simultaneously.

The machine controls:

- Winding turns

- Wire tension

- Speed

- Layer distribution

- X/Y/Z/S/A axis guide movement

Optional Twisting : If enabled, the twisting unit activates to prepare wire for high-frequency inductors.

Optional Taping : Coil receives insulation taping after winding.

Wire Cutting : Pneumatic cutters trim the copper wire with precision.

Automatic Unloading : Finished coils drop into the unloading tray.

Ready for Next Cycle : The machine resets automatically and begins the next set.

Cycle Time & Production Capacity

The cycle time depends on:

- Wire gauge

- Winding turns

- Bobbin size

- Optional taping/twisting

Standard Cycle Time

-

15 seconds per cycle (fine wires)

-

20 seconds per cycle (heavy wires)

Output: Per Hour

-

2,160 – 2,880 coils/hour

Output: Per 8-Hour Shift

-

17,280 – 23,040 coils

Output: Per 16-Hour Production

-

34,560 – 46,080 coils

This high productivity makes the machine ideal for:

- SMPS factories

- LED driver manufacturers

- Charger/adapter manufacturers

- Telecom and networking device manufacturers

- OEM production lines

Advantages of Using This Machine

High Accuracy : Servos and encoders ensure exact turn count and layer alignment.

Uniform Quality : Each coil is identical, reducing rejection rates.

Low Dependence on Labor : Only one operator is needed for loading bobbins.

Cost-Effective : Reduces cost per coil due to:

- High speed

- Low manpower

- Minimum rejections

Multi-Model Support : Store programs for EE13, EE16, EE20, EE25, drum coil etc.

Long Machine Life : Built with industrial-grade components.

Easy to Operate : Simple HMI interface with password protection.

Scalable Production : Can run continuously 24×7 for high-volume requirements.

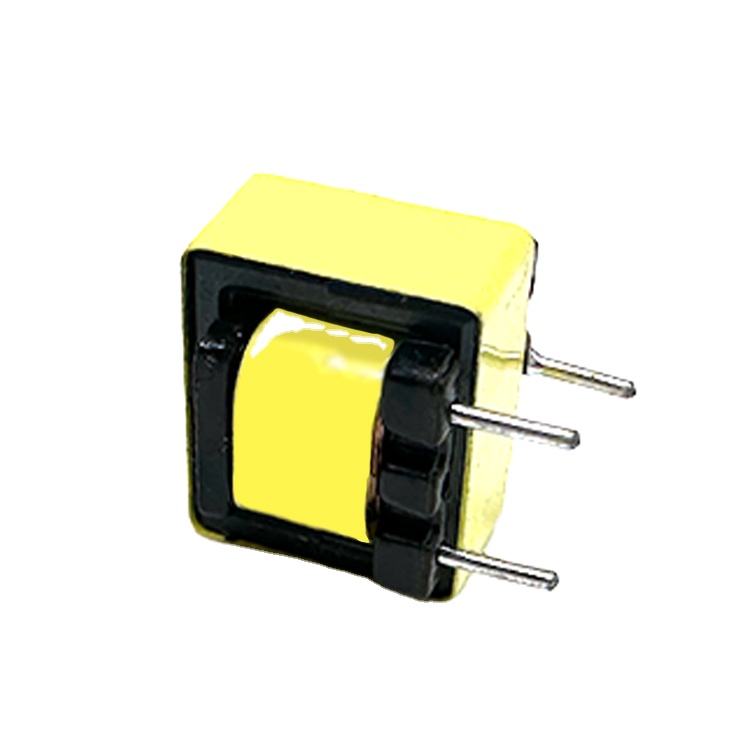

Technical Specifications

| Parameter | Specification |

|---|---|

| Machine Type | Automatic Inductor Coil Winding |

| Supported Bobbins | EE10–EE25, EFD, Drum Coil, UU9.8 EMI, Sensor coil or custom |

| Number of Spindles | 12/16/20/24 spindles |

| Cycle Time | 15–20 seconds |

| Control System | 5-axis servo motion |

| Interface | Touch-screen HMI |

| Programs | Multi-program support |

| Wire Type | 0.06 ~ 0.6 mm |

| Tension System | Magnetic or Servo |

| Pneumatics | Airtac/SMC |

| Cutting System | Pull Cut or Blades |

| Optional Units | Taping, Twister, Pneumatic scissors |

| Structure | Heavy-duty steel |

| Power | AC 220V / 50Hz |

| Warranty | 1 Year |

| Installation | Pan-India |

| Training | Provided on customer site |

Installation & After-Sales Support

Deptronics Technologies provides:

- On-site installation

- Operator training

- Telephone and video call support

- Spare parts availability

- Annual maintenance contracts (optional)

- Quick response service team

We ensure that every customer receives complete assistance from installation to full-scale production.

Machine’s Application Areas

This machine is widely used in:

- SMPS power supplies

- LED drivers

- Telecom and networking devices

- Mobile chargers

- Industrial automation controllers

- Consumer electronics

- Power adapters

- EV charger modules

Any industry that uses ferrite inductors can benefit from this machine.

Why Manufacturers Prefer Deptronics’ Machine

Strong Mechanical Design : Ensures stability during high-speed operation.

Reliable Electronics : Servo motors, controllers, and pneumatics are from reputed brands.

Smooth Operation : HMI interface allows easy setup.

Flexible Customization : Machines can be customized based on bobbin type and winding pattern.

High Return on Investment : Due to high output and low manpower.

Final Thoughts

The Automatic Inductor Coil Winding Machine from Deptronics Technologies is a reliable, high-speed solution for manufacturers who want to scale their production while maintaining precision and consistency.

With its 12-spindle system, servo-driven winding heads, automatic loading/unloading, optional taping/twisting, and robust construction, it is engineered to meet the demands of modern electronics manufacturing.

This machine is ideal for companies looking for:

- High daily output

- Improved quality

- Reduced manpower

- Consistent coil geometry

- Long-term performance

Deptronics ensures unmatched quality, service, and support for every installation.

If your business is ready to take the next step toward inductor coil production excellence, contact DepTronics Technologies today and transform your manufacturing line into a world-class automated setup.

DEPTRONICS TECHNOLOGIES

Contact : Deepanshu Saxena

WhatsApp/Mobile : +91-8800622761

Email : [email protected]

Reviews

There are no reviews yet.