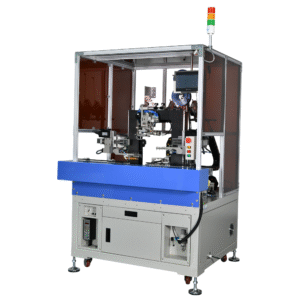

Machine Overview: Immobilizer Coil Automatic Winding

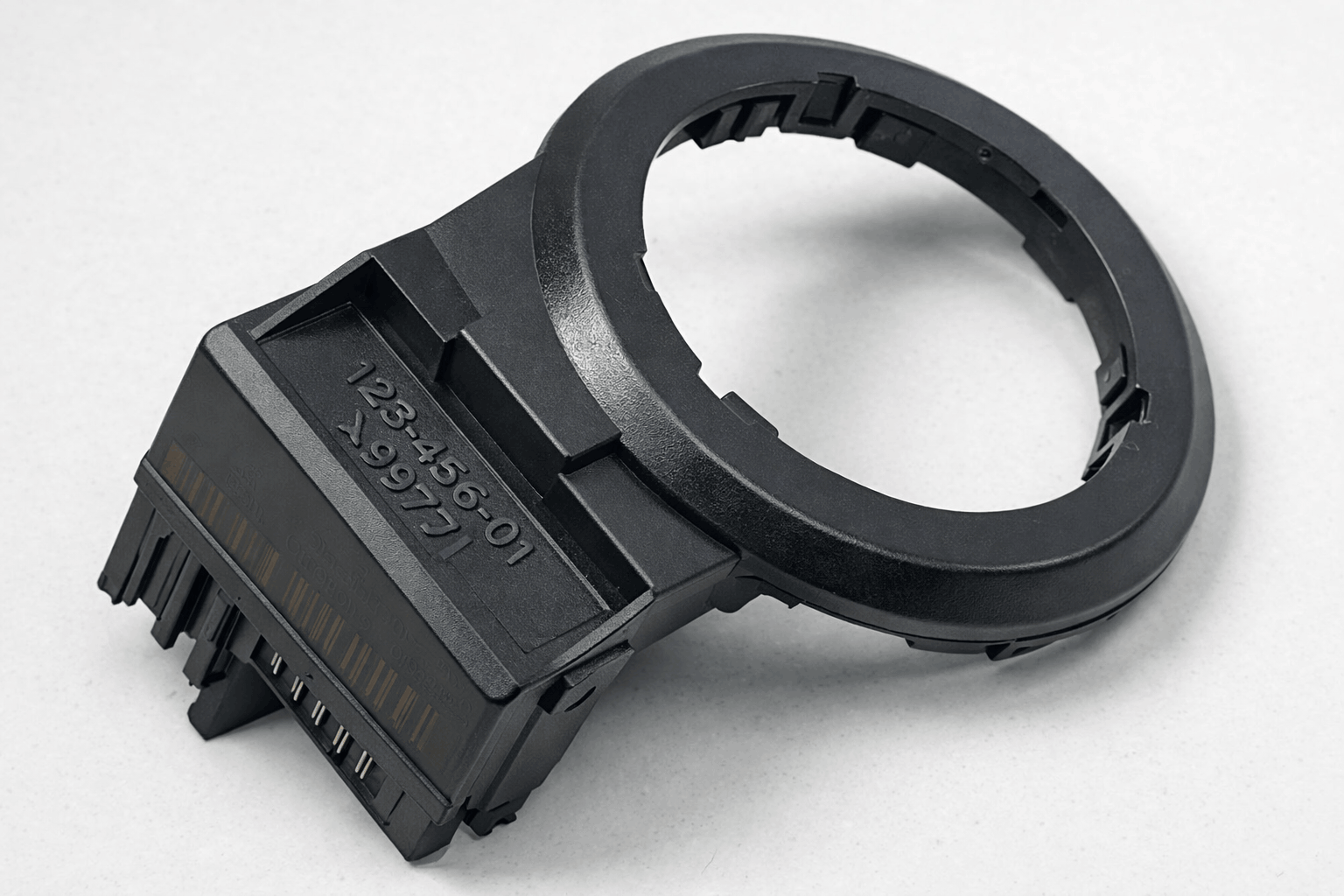

The 12 spindle immobilizer coil winding machine is a fully servo-controlled system designed for fine copper wire winding on immobilizer and ignition coil bobbins.

Core Capabilities:

- Simultaneous winding on 12 spindles

- Ultra-fine wire handling with closed-loop tension control

- Programmable winding turns, layers, and pitch

- Automatic wire cutting and clamping

- Recipe-based program storage

Detailed Working Principle

Step 1: Bobbin Loading

Bobbins are manually or automatically loaded onto the 12 spindles depending on the production line configuration.

Step 2: Wire Feeding & Tension Control

Each spindle is equipped with independent tensioners to maintain uniform copper wire tension throughout the winding cycle.

Step 3: Precision Winding

Servo motors ensure accurate turns, pitch, and layering as per the programmed recipe. All 12 coils are wound simultaneously.

Step 4: Wire Termination

After completion of winding, the machine performs automatic wire clamping and cutting to ensure consistent lead length.

Step 5: Unloading

Finished coils are removed manually or transferred automatically to the next process such as soldering, taping, or testing.

Machine Construction & Mechanical Design

Heavy-Duty Machine Frame

The machine is built on a vibration-free, rigid industrial frame to ensure stability during high-speed winding. Structural rigidity is critical to maintain winding accuracy over long production shifts.

Individual Spindle Drive System

Each of the 12 spindles is driven through precision servo motors or synchronized drive mechanisms. This ensures:

- Identical RPM across spindles

- Controlled acceleration and deceleration

- No wire stretching or slack formation

Advanced Wire Handling System

Immobilizer and ignition coils typically use fine enamel copper wire, where even micro-level tension variation can affect inductance values.

Closed-Loop Wire Tension Control

The machine uses advanced tensioners to maintain consistent wire tension throughout the winding process. This results in:

- Perfect layer formation

- No enamel damage

- Stable electrical characteristics

Automatic Wire Break Detection

Sensors continuously monitor wire continuity. In case of wire breakage, the machine stops automatically, preventing defective coils.

Technical Specifications of Immobilizer Coil Winding Machine

| Specification | Details |

|---|---|

| Number of Spindles | 12 / 16 / 20 (customized) |

| Motors | High-precision servo motors |

| Wire Tensioners | Magnetic or optional servo type |

| Spindle Gap | 50.6/61.2/72 mm |

| Max Bobbin Size | 30-50 mm swing |

| Winding Direction | CW / CCW |

| Spindle Stop Accuracy | ±0.1° |

| Copper Wire Range | 0.02–0.60 mm |

| Wire Anchoring Angle | 0° / 90° (motorized also customized) |

| Power Supply | AC 220V, 50Hz |

| Power Consumption | 2.5 kW approx. |

| Air Pressure | 4–6 kg/cm² |

| Optional Devices | Twister, cutter, enamel remover |

| Optional Automation | Auto loading/unloading, taping, clipping, waste wire discharge |

This technical framework ensures that the machine is capable of handling even the most demanding ignition applications.

Winding Accuracy & Programmability

Servo-Controlled Winding Logic

The heart of the machine is a PLC-based control system with servo drives. This allows precise control over:

- Number of turns

- Layer count

- Pitch and traverse movement

- Start and end positioning

Recipe-Based Operation

Multiple coil models can be stored as recipes. Operators can switch between products with minimal downtime, making the machine ideal for manufacturers handling multiple SKUs.

Integration With Complete Ignition Coil Production Line

The 12 spindle winding machine can be seamlessly integrated with:

- Automatic soldering machines

- Flux dipping systems

- Resistance & inductance testing stations

- Final assembly and potting lines

Comparison: Manual vs Semi-Automatic vs 12 Spindle Automatic Machine

| Parameter | Manual | Semi-Automatic | 12 Spindle Automatic |

|---|---|---|---|

| Output | Low | Medium | Very High |

| Consistency | Poor | Moderate | Excellent |

| Labor Dependency | High | Medium | Low |

| Automotive Suitability | No | Limited | Yes |

ROI & Business Benefits

Investing in a 12 spindle immobilizer coil automatic winding machine offers:

- Faster payback due to high output

- Reduced labor and training costs

- Improved consistency and customer confidence

- Scalability for future demand

Real-World Manufacturing Use Cases

Case 1: Two-Wheeler Immobilizer Coil Manufacturing

Two-wheeler OEMs require extremely high volumes with stable quality. A single 12 spindle winding machine can support multiple vehicle models by switching recipes, enabling flexible production planning.

Case 2: Passenger Car Ignition Coil Supplier

Tier-1 suppliers supplying ignition modules benefit from the machine’s repeatability, ensuring zero customer complaints related to signal mismatch or starting issues.

Case 3: Job-Work Manufacturer Scaling Operations

For job manufacturers, upgrading from semi-automatic to a 12 spindle automatic machine transforms business capability—higher output, better margins, and long-term contracts.

Installation & After-Sales Support

Deptronics Technologies provides:

- On-site installation

- Operator training

- Telephone and video call support

- Spare parts availability

- Annual maintenance contracts (optional)

- Quick response service team

We ensure that every customer receives complete assistance from installation to full-scale production.

Why Deptronics Technologies as a Trusted Partner for Automation

Investing in an automatic relay coil winding machine is a long-term strategic decision. Beyond machine specifications and output capacity, what truly defines success is dependable technical support, fast service response, and long-term production reliability. This is where DepTronics Technologies clearly stands apart in the Indian market.

DepTronics has established itself as a reliable automation partner for industries seeking advanced coil winding and production line solutions. The company’s strength lies not only in supplying high-performance machines, but also in ensuring uninterrupted production throughout the machine’s lifecycle.

Key Reasons Industries Prefer DepTronics Technologies

Pan-India Service Presence

DepTronics provides installation, commissioning, operator training, and technical support across all major manufacturing regions in India, ensuring customers receive timely assistance wherever they operate.

Ready Availability of Spare Parts

To avoid costly production stoppages, DepTronics maintains local inventory of critical spare components, allowing faster replacements and reduced machine downtime.

Specialized Technical Team

A dedicated team of experienced engineers supports customers during machine installation, process optimization, troubleshooting, and advanced operational training.

Application-Specific Machine Programming

Each relay coil application is unique. DepTronics offers customized machine programming to match customer-specific coil parameters, production targets, and quality requirements.

Choosing DepTronics Technologies means more than acquiring a machine—it means partnering with a company committed to long-term performance, production stability, and industrial growth, supported by both local service strength and international manufacturing standards.

Contact Us

For machine inquiries, pricing, or customization options, contact us today!

DEPTRONICS TECHNOLOGIES

📌 Contact Person: Deepanshu Saxena

📞 WhatsApp/ Mobile: +91-8800622761

🌐 Website: https://coilwinder.in/

📧 Email: [email protected]

Ravichandran Karthik –

stable machines, we are using from last 5 years, performance-wise very stable and consistant, technical team is also very supportive