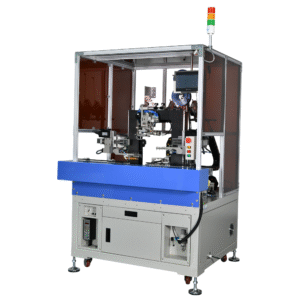

Overview: 12-Spindle Contactor Winding Machine

The 12-spindle configuration means the machine can wind 12 coils simultaneously in a single production cycle. Each spindle replicates the same programmed turns, pitch, speed, and tension settings. The result is absolute consistency across all coils.

Core Highlights

- 12 contactor coils produced per cycle

- Ideal for high-volume manufacturers

- Fully programmable winding parameters

- Servo or stepper-driven motion control

- Magnetic tensioners for maximum stability

- Optional servo tensioners for premium control

- Optional taping and twisting attachments

- Auto-loading and auto-unloading system

- Supports fine-gauge to mid-gauge copper wires

The machine is highly robust, built for continuous 24×7 operation with minimal maintenance.

Working Video

Step-by-Step Working Process

Below is the complete cycle that explains how the machine works:

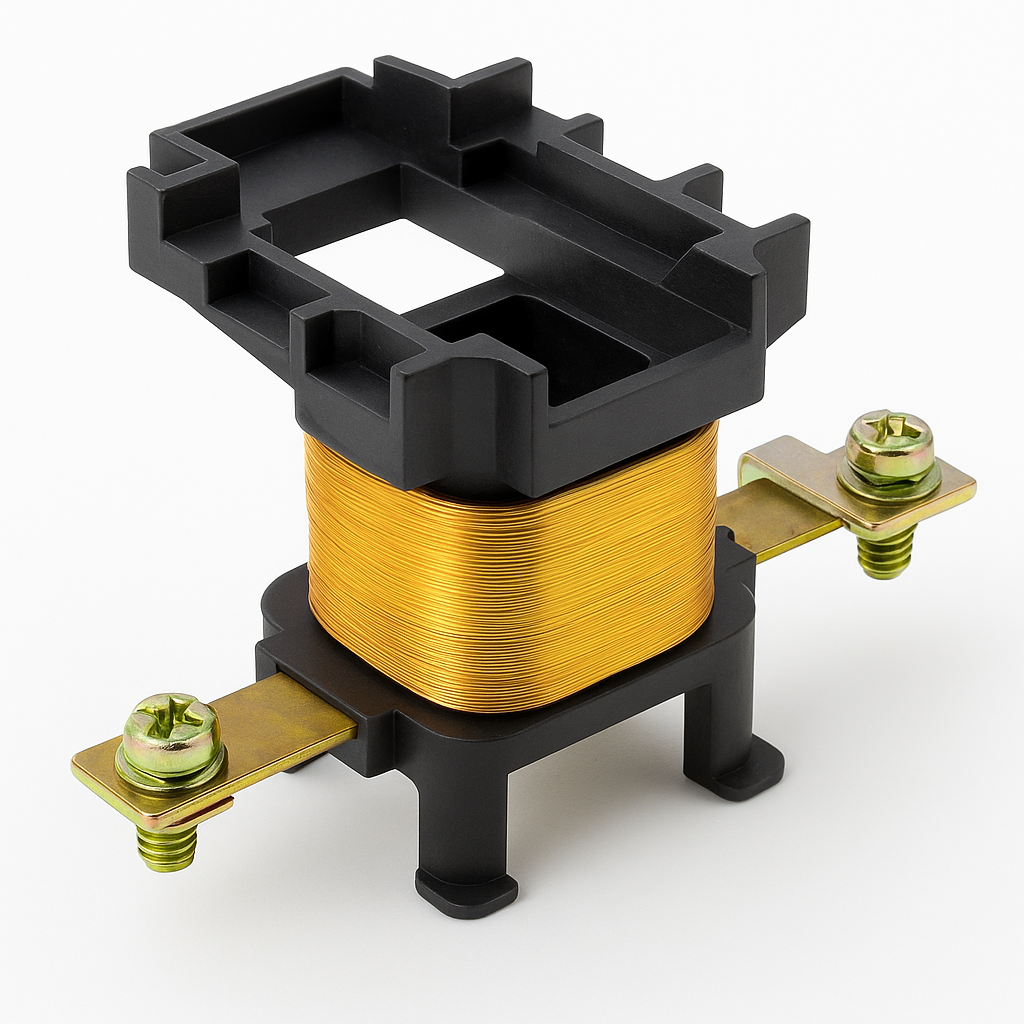

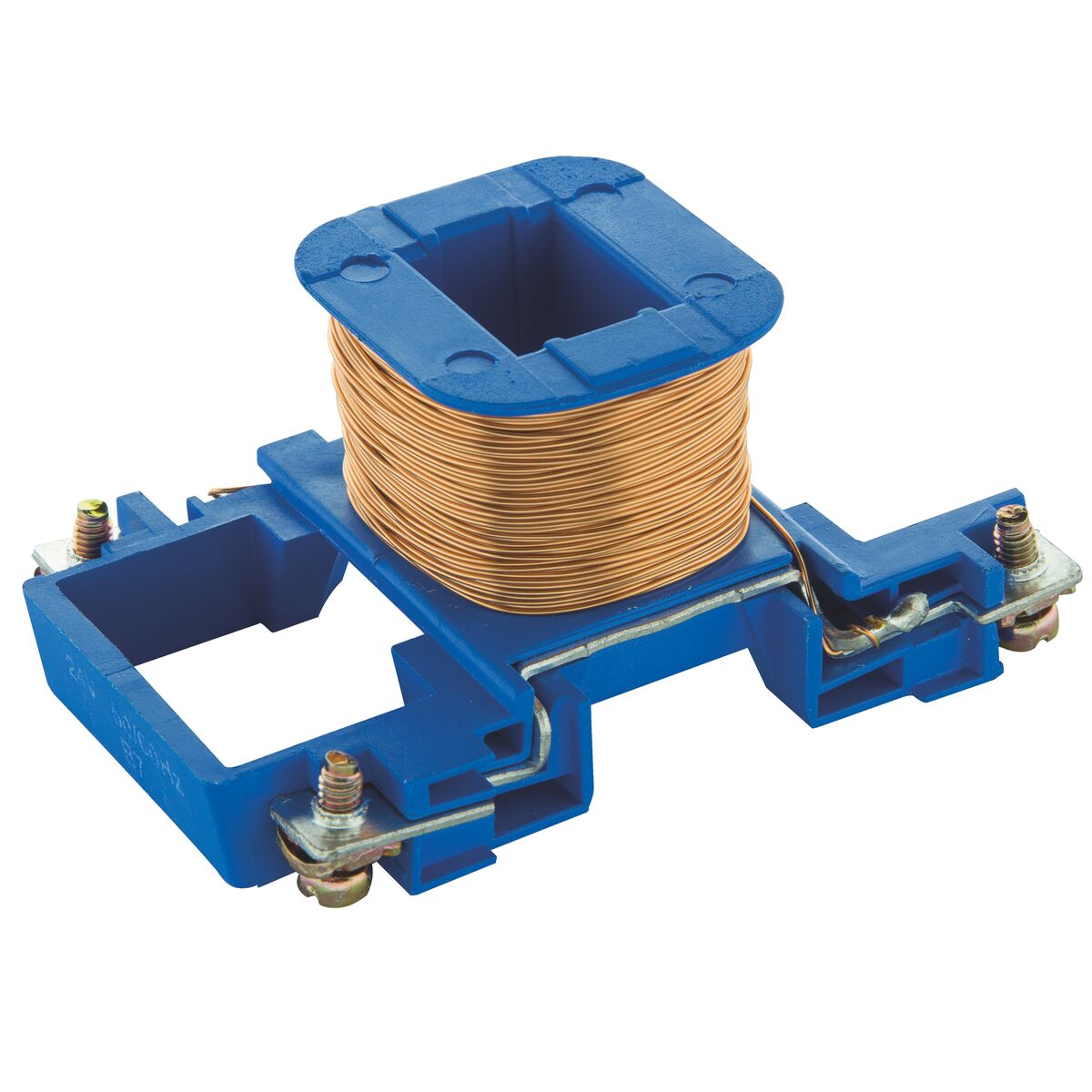

Step 1: Operator Loads Blank Bobbins

The operator collects blank plastic contactor bobbins and arranges them into the loading fixture.

This is the only manual step in the entire cycle, making the process extremely labor-saving.

Step 2: Automatic Loading to Mandrels

Once the cycle starts:

- A pneumatic or robotic mechanism picks up bobbins from the loading nest

- Places them accurately onto the 12 mandrels

- Ensures proper clamping for high-speed winding

This automation eliminates alignment issues and reduces human error.

Step 3: Winding Process Begins

The machine now starts executing the programmed winding parameters:

- RPM control

- Layer-by-layer precision

- Traverse movement

- Wire guiding

- Tension feedback

Each spindle winds its assigned coil simultaneously.

The winding time typically ranges from 20 to 30 seconds, depending on wire gauge and number of turns.

Step 4: Finishing & Wire Cutting

The system automatically performs:

- End-turn completion

- Wire cutting

- Lead arrangement

- Optional tinning (depending on configuration)

Step 5: Automatic Unloading

After winding:

- Pneumatic arms remove the finished coils

- Deposits them into output trays

- Prepares mandrels for the next batch

This enables continuous mass production without stopping.

Key Features of the Machine

Below are the essential features that make this machine the top choice in India’s coil manufacturing industry.

12-Spindle High-Volume Winding System

- All 12 mandrels operate together

- Perfect for bulk orders

- Reduces cycle time drastically

- Each spindle is synchronized for maximum accuracy

- Each spindle is synchronized for maximum accuracy

Magnetic Tensioners (Optional: Servo Tensioners)

Magnetic tensioners provide:

- Stable tension

- Smooth wire feeding

- Minimal breakage

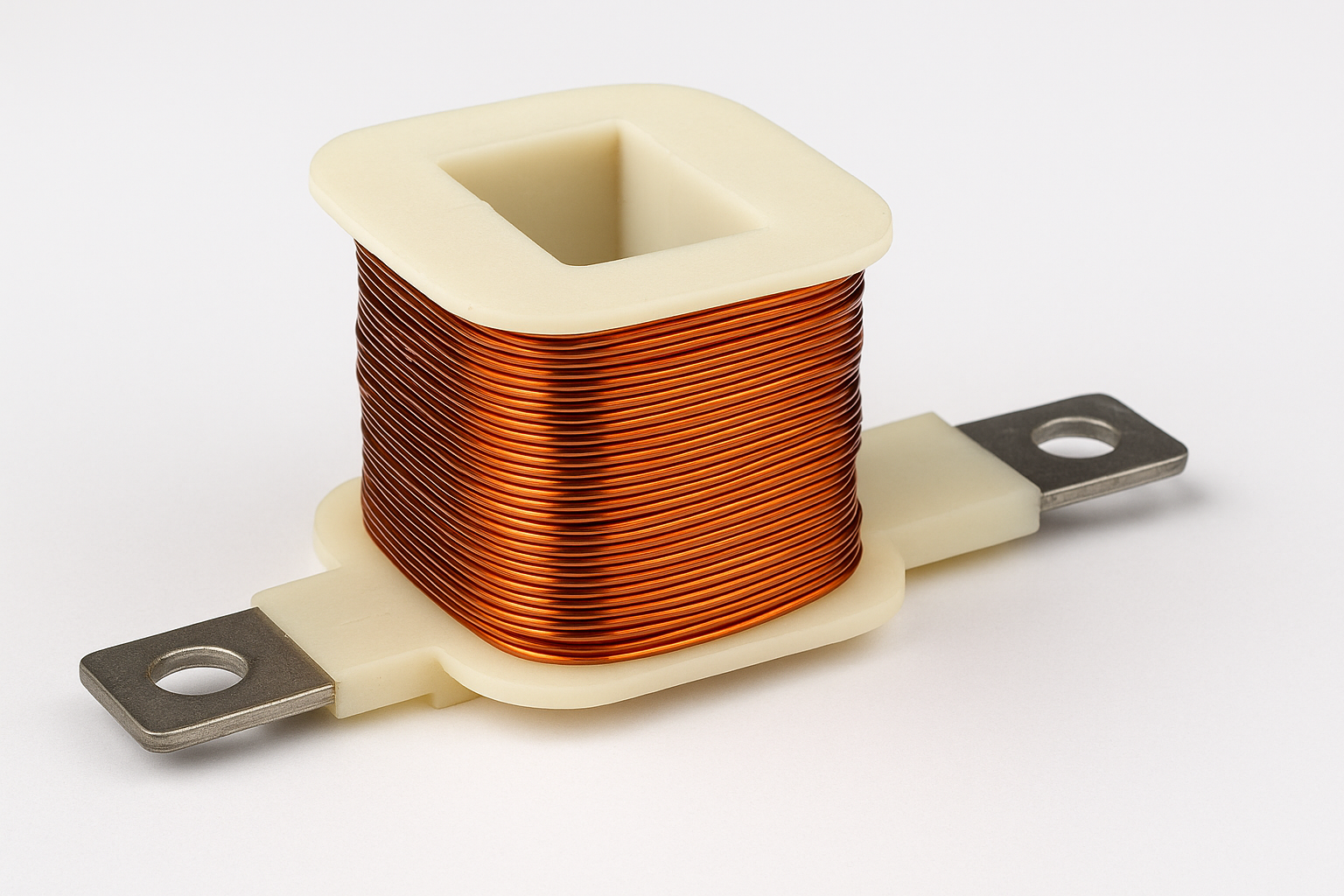

Users requiring extreme precision (especially for fine gauge wires 0.05–0.14 mm) can upgrade to servo tensioners, which offer:

- Real-time tension control

- Digital programming

- Constant tension irrespective of spool diameter

Optional Taping Attachment

This attachment automatically tapes the wound coil after winding.

Benefits:

- Increases speed

- Reduces manual taping work

- Improves coil finishing quality

Optional Copper Wire Twisting Unit

Useful when using multiple fine-gauge wires (e.g., parallel wires).

The twisting unit ensures:

- No crossover

- Smooth feeding

- Higher winding reliability

- Avoids insulation damage

Advanced Control System

- Touchscreen HMI

- Multiple programs storage

- Parameter locking

- Error alarms

- Easy user interface

Even new operators can run the machine with minimal training.

High Durability & Industrial Build Quality

- Heavy-duty frame

- Precision machined mandrels

- Designed for long production shifts

- Imported motors and controllers

Advantages of the Contactor Coil Winding Machine

1. Very High Production Output

Winding 12 coils at a time massively increases daily output.

A single machine can easily produce 12,000–18,000 coils per day depending on shift length and winding parameters.

2. Extreme Accuracy

- Identical winding across all coils

- Perfect tension control

- No human variation

- Reduced rejection rates

Accuracy is critical for contactor coil performance and heating control.

3. Huge Labour Saving

A process that normally needs 8–10 workers can now be run with just one operator.

This leads to major annual savings in:

- Wages

- Training

- Absenteeism

- Manual errors

4. Stable Quality for Export-Grade Requirements

Manufacturers exporting electrical products need zero-defect coils.

Automatic winding ensures stable, repeatable quality.

5. Easy to Maintain

The machine is simple to service, with:

- Minimal consumables

- Accessible mechanical parts

- On-screen diagnostic messages

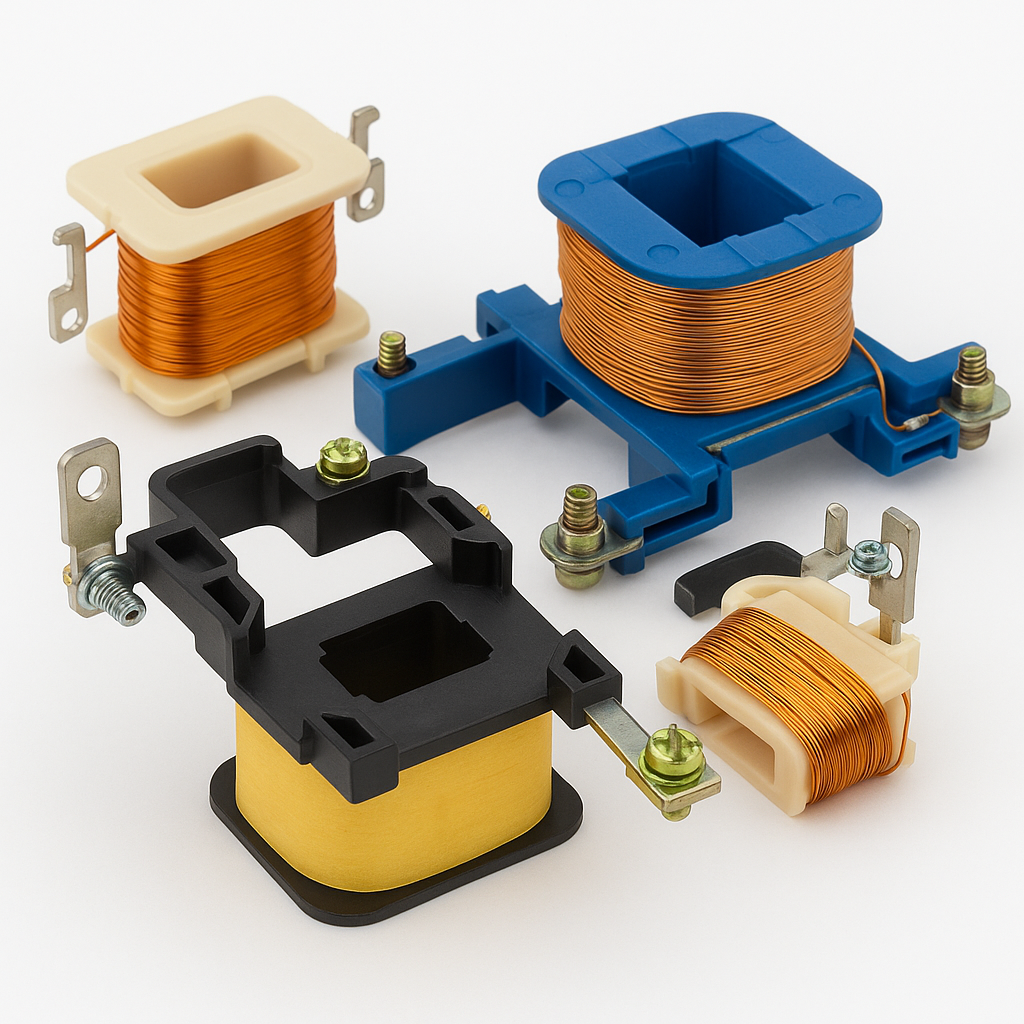

6. Supports Multiple Bobbin Sizes

Ideal for different models of contactor coils used in:

- LT panels

- Electrical relays

- Switchgear

- HVAC contactors

Technical Specifications of Contactor Coil Winding Machine

| Specification | Details |

|---|---|

| Number of Spindles | 12 / 16 / 20 (customized) |

| Motors | High-precision servo motors |

| Wire Tensioners | Magnetic or optional servo type |

| Spindle Gap | 50.6/61.2/72 mm |

| Max Bobbin Size | 30-50 mm swing |

| Winding Direction | CW / CCW |

| Spindle Stop Accuracy | ±0.1° |

| Copper Wire Range | 0.02–0.60 mm |

| Wire Anchoring Angle | 0° / 90° (motorized also customized) |

| Power Supply | AC 220V, 50Hz |

| Power Consumption | 2.5 kW approx. |

| Air Pressure | 4–6 kg/cm² |

| Optional Devices | Twister, cutter, enamel remover |

| Optional Automation | Auto loading/unloading, taping, clipping, waste wire discharge |

This technical framework ensures that the machine is capable of handling even the most demanding contactor applications.

Who Uses This Machine? (Target Industries)

The machine is perfectly suited for:

- Contactor manufacturers

- Relay manufacturers

- Electrical panel OEMs

- Switchgear companies

- EMS contract manufacturers

- Coil manufacturing jobwork units

- Companies planning factory automation

Any industry producing 5,000+ coils per day will benefit immensely from this technology.

ROI (Return on Investment) Calculation

Let’s calculate the ROI for a typical manufacturer.

1. Cycle Time

Average cycle time = 25–30 seconds

Meaning: 12 coils every 25–30 seconds

Approx. output per hour:

12 coils × 120 cycles ≈ 1,440 coils/hour

Output per 10-hour shift:

1,440 × 10 = 14,400 coils/day

2. Labour Savings

Manual process: Requires 8–9 workers

Automatic machine: Only 1 operator required

Savings:

Approx. ₹80,000–₹150,000 per month depending on city and labour category.

3. Rejection Reduction

Manual rejection: 3–8%

Automatic rejection: <1%

Savings: Another ₹20,000–₹40,000/month

4. Payback Period

Total estimated savings = ₹100,000 to ₹1,50,000 per month

Machine ROI = 8–12 months

(Sometimes even faster based on production volume)

Final Thoughts

The Automatic 12-Spindle Contactor Coil Winding Machine is one of the most powerful investments any electrical component manufacturer can make. It increases production capacity, enhances coil precision, reduces labour dependency, and stabilizes long-term growth.

With optional features like taping, twisting, and servo tensioning, the machine becomes highly customizable for every factory requirement.

If you are planning to scale your production, reduce costs, and improve quality, this machine is undoubtedly the best choice for 2025 and beyond.

Contact Us

For machine inquiries, pricing, or customization options, contact us today!

DEPTRONICS TECHNOLOGIES

📌 Contact Person: Deepanshu Saxena

📞 WhatsApp/ Mobile: +91-8800622761

🌐 Website: https://coilwinder.in/

📧 Email: [email protected]

For mass production of relay coils, check our “Automatic Production Line for Mass Manufacturing of Relay Coils”

We provide end-to-end support, from machine selection to installation guidance and after-sales service—helping your factory achieve world-class automation standards.

Reviews

There are no reviews yet.