Why the Industry Is Moving Toward Automatic Winding Machines

Higher Design Complexity

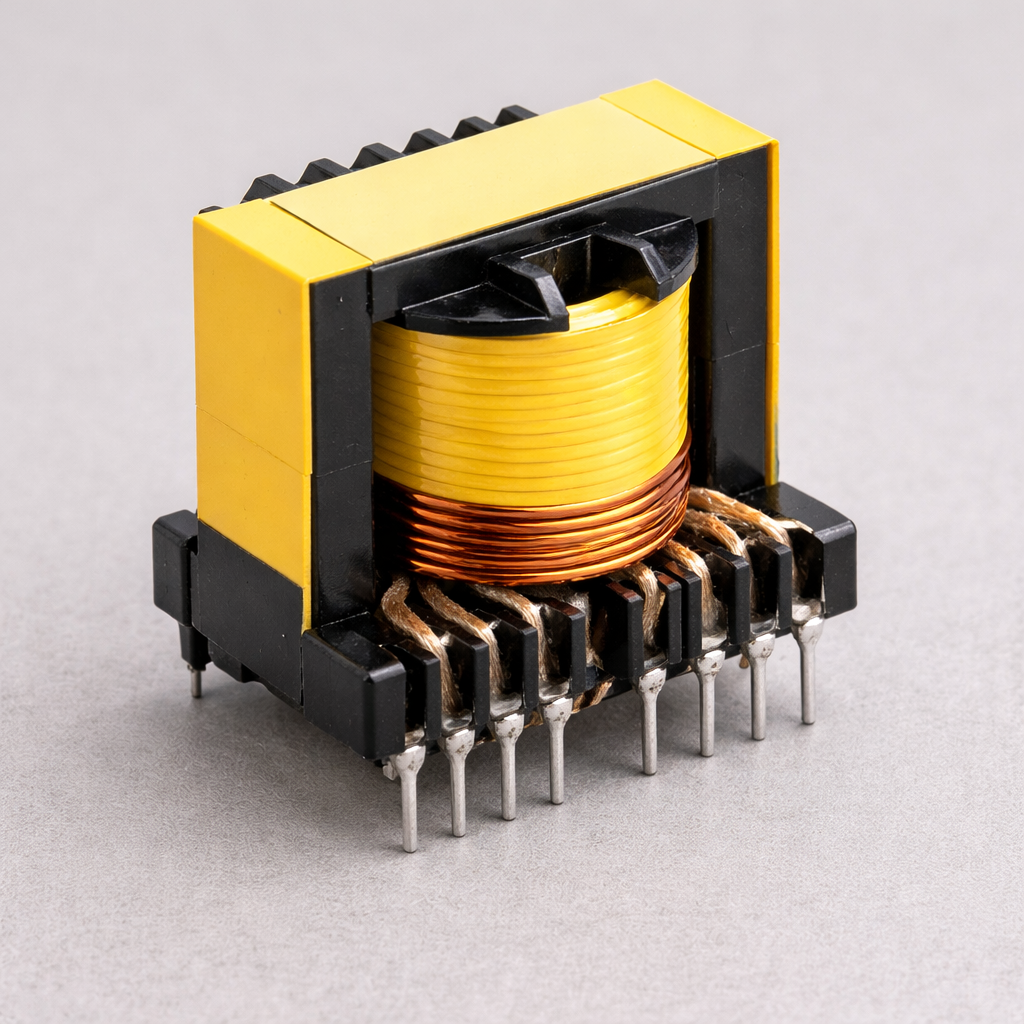

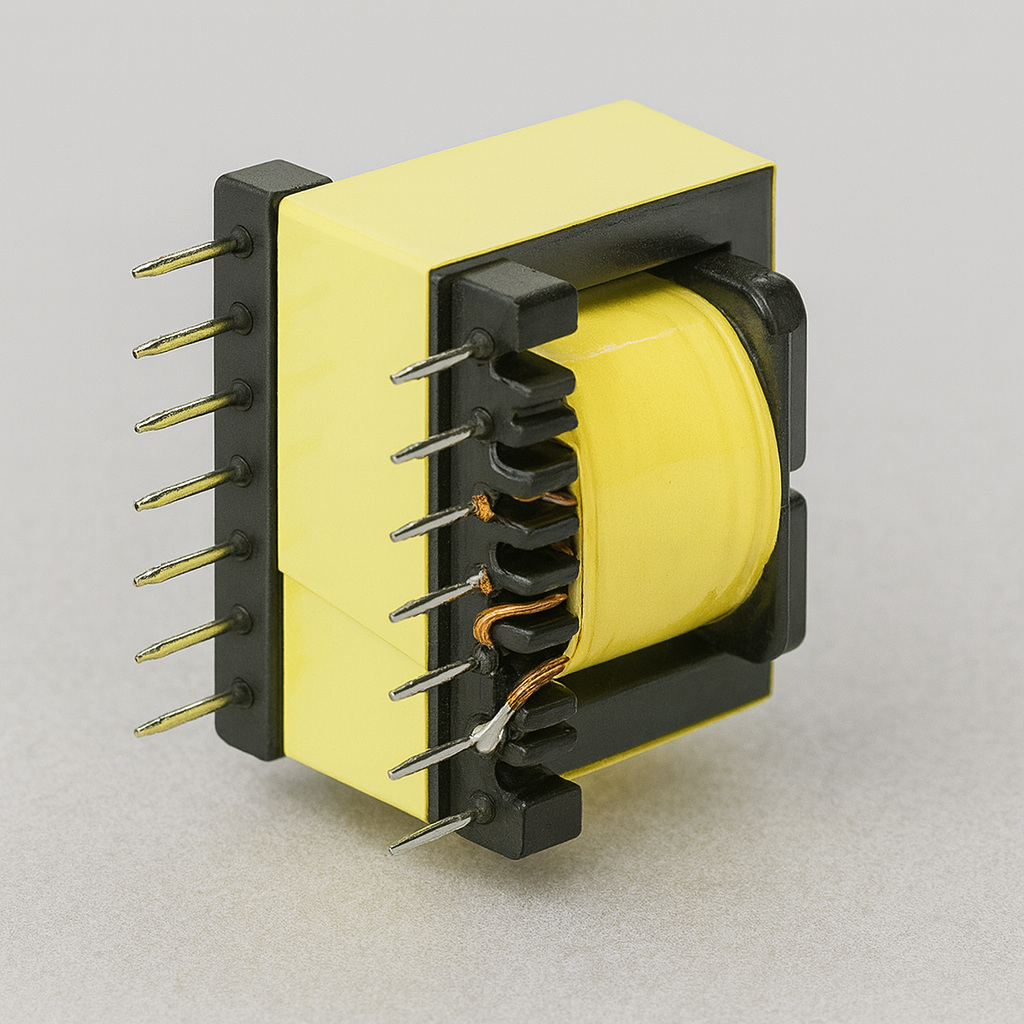

Modern SMPS transformers use multi-layer windings, parallel wires, and multiple insulation stages that demand high precision.

Consistent Quality Requirement

Automatic machines ensure repeatable winding quality, stable electrical parameters, and uniform insulation across batches.

Reduced Labor Dependency

Automation minimizes reliance on skilled winding operators and eliminates human fatigue and variation.

Higher Production Output

Automatic winding delivers faster cycle times and higher daily production compared to manual methods.

Lower Rejection & Rework

Digital process control significantly reduces winding defects and scrap rates.

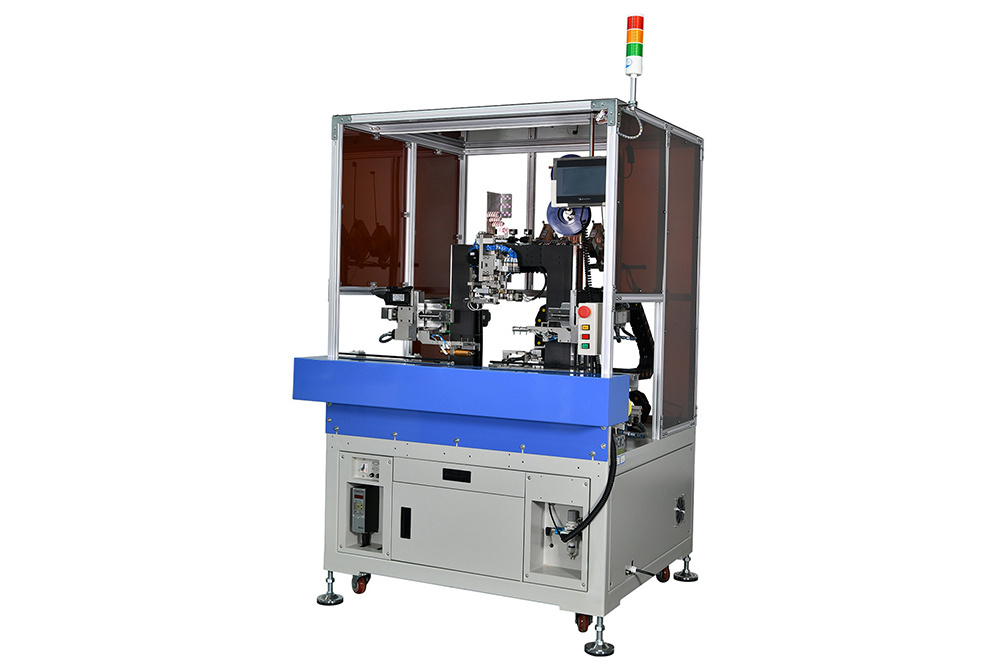

Overview of the Automatic SMPS Winding Solution

The Double ARM | Automatic SMPS Transformer Winding Machine is a fully automatic system designed to perform complex transformer winding operations in a single continuous cycle.

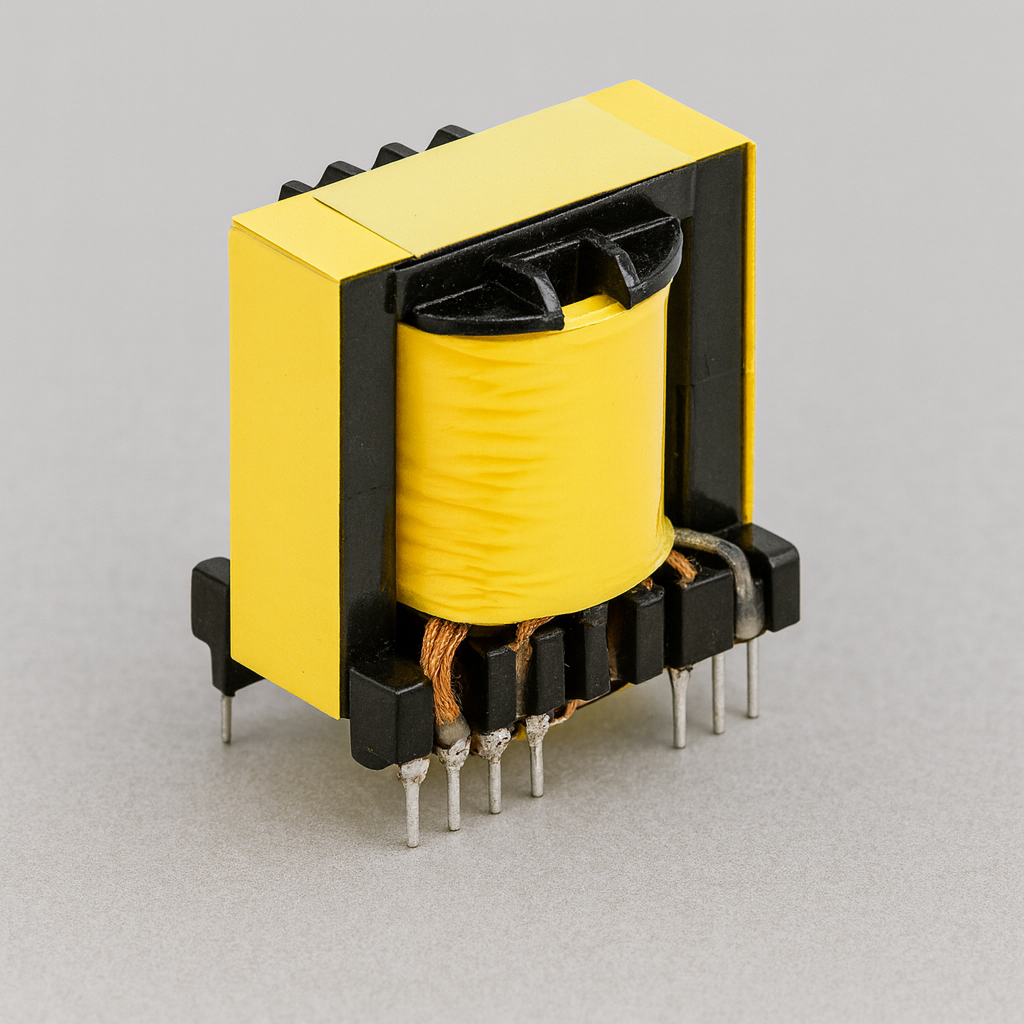

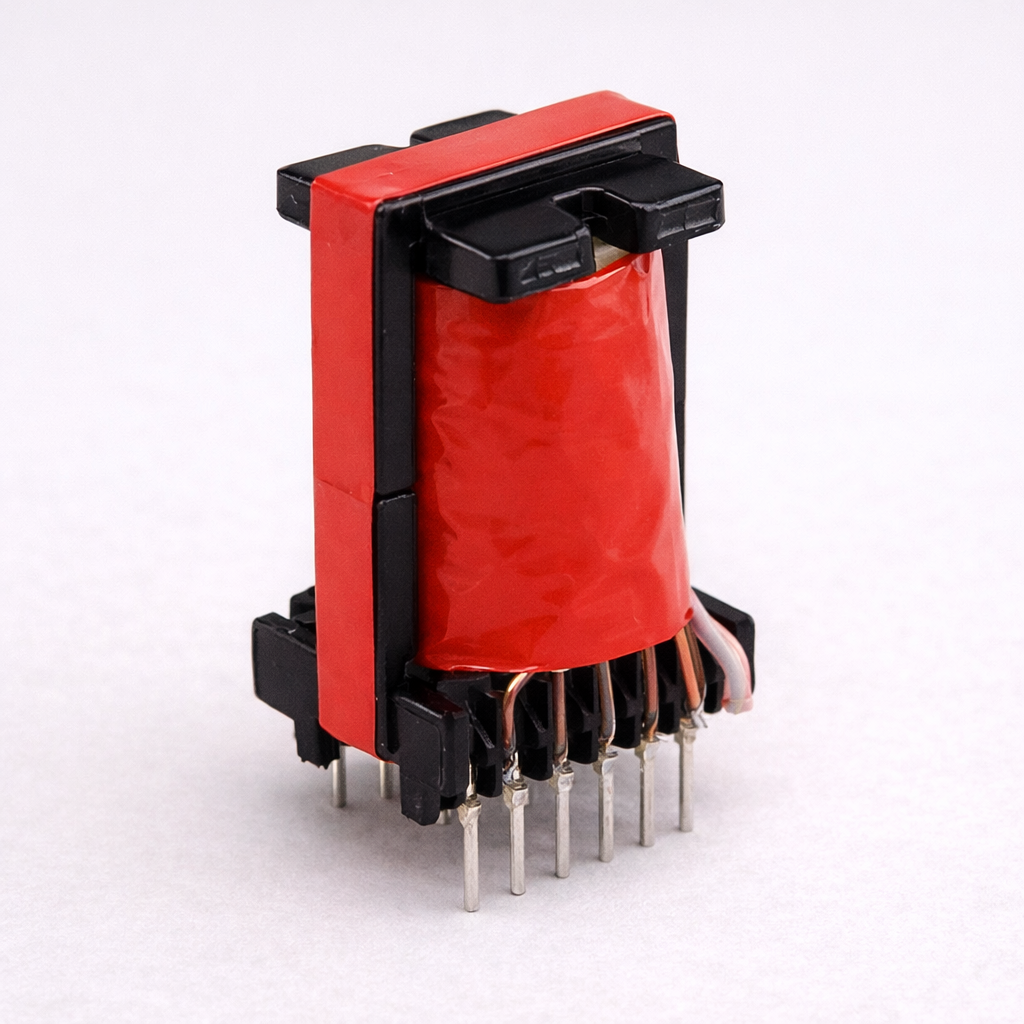

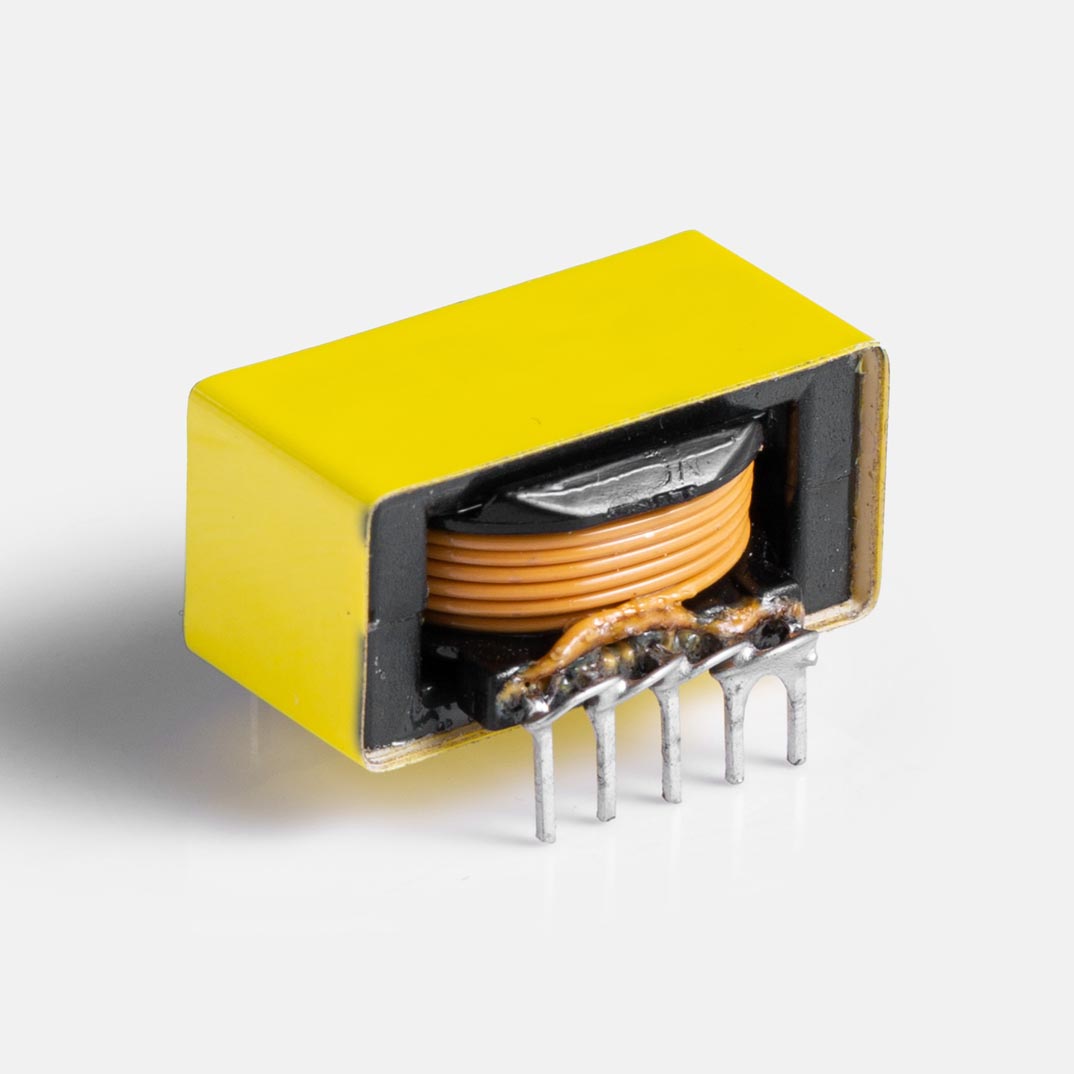

Supported Transformer Types

- EE / EER series

- EFD series

- ETD series

- PQ series

- RM / ER series

- Custom ferrite bobbins

These formats are widely used in SMPS power supplies, LED drivers, telecom power modules, EV chargers, and industrial electronics.

Machine’ Operation Video

Typical Transformer Winding Cycle

-

Automatic Bobbin Loading

Empty bobbin is loaded manually or via optional auto-loader. -

First Winding Operation

Selected wire and sleeve are automatically inserted, winding is completed, and insulation tape is applied. -

Second Winding Operation

A different wire and sleeve combination is selected automatically, followed by winding and taping. -

Third & Fourth Windings (If Required)

Additional windings are completed as per the programmed recipe. -

Automatic Unloading

Finished transformer bobbin is unloaded to tray or conveyor for next process.

Step-by-Step Operational Breakdown

1. Bobbin Loading

- Manual loading or optional automatic loader

- High-precision fixture ensures stable alignment

- Supports single or multi-bobbin configurations

2. Program Selection

- Operator selects transformer model via touchscreen HMI

- Programs are pre-configured based on winding data

- No mechanical changeover required

3. Dual ARM Synchronized Winding

Both ARMs work simultaneously to complete:

- Primary winding

- Secondary winding

- Feedback winding

- Auxiliary winding

Supported winding types:

- Layer winding

- Section winding

- Interleaved winding

- Bifilar / Trifilar winding

- Tap winding

4. Multi-Axis Servo Control

- Up to 14-axis servo coordination

- Precise control of tension, traverse, and alignment

- High-torque motors maintain speed even with thick or bunch wires

5. Integrated Automation Modules

- Automatic wire cutting & holding

- Automatic sleeve insertion

- Automatic taping between windings

- Automatic unloading to tray or conveyor

Technical Specifications (Typical Configuration)

| Feature | Specification |

|---|---|

| Winding Arms | 2 (Independent & Synchronized Double ARM) |

| Axis Control | 14-Axis Servo Control System |

| Max Bobbin Size | Up to PQ40 (custom supported) |

| Wire Diameter Range | 0.03 mm – 1.2 mm |

| Wire Types | Enameled Copper, Litz, Bifilar, Trifilar, Bunch |

| Parallel Wire Capability | 2–4 wires simultaneously |

| Sleeve Handling | Up to 3 sleeve sizes per cycle |

| Tension Control | Digital programmable (individual per wire) |

| Winding Speed | Up to 12,000 RPM |

| Control Interface | 7” / 10” Industrial Touchscreen HMI |

| Program Storage | 50+ recipes (expandable) |

| Power Supply | 230V / 50Hz / Single Phase |

| Pneumatic Supply | 5–6 bar clean, dry air |

| Safety | Emergency stop, guarding & interlocks |

Industries & Applications

This machine is ideal for:

- SMPS power supply manufacturers

- LED driver manufacturers

- Telecom power system suppliers

- Industrial automation OEMs

- Medical electronics manufacturers

- EV charger & renewable energy system producers

Production Capacity & Scalability

- Shorter cycle time per transformer

- Easy scalability by adding parallel machines

- Seamless integration into conveyor-based production lines

A future-ready solution for growing production demands.

Why Choose Deptronics Technologies

Deptronics Technologies delivers complete automation solutions, not just machines.

Our Strengths

- Deep expertise in SMPS & ferrite transformer automation

- Strong partnerships with advanced global manufacturers

- Transparent project execution

- Reliable installation & after-sales support in India

- Long-term focus on customer success

Installation, Training & Support

We provide:

- Pre-dispatch inspection support

- Installation coordination

- Operator & maintenance training

- Preventive maintenance guidance

- Ongoing technical & spare support

Final Thoughts

The SMPS Transformer Winding Machine – Double ARM is a strategic investment for manufacturers aiming for precision, productivity, and scalability. As SMPS designs continue to evolve, advanced winding automation is no longer optional — it is essential.

With the right machine and the right automation partner, manufacturers can achieve consistent quality, faster growth, and global competitiveness.

Frequently Asked Questions (FAQs)

Q1. Can the machine handle multiple transformer models?

Yes, through recipe-based programming.

Q2. Is customization possible?

Yes, machine configuration can be customized to transformer design.

Q3. What insulation sleeves are supported?

PTFE, polyester, and custom sleeves.

Q4. Can it integrate into a full production line?

Yes, it integrates with soldering, taping, testing, and conveyor systems.

Contact Us

For machine inquiries, pricing, or customization options, contact us today!

DEPTRONICS TECHNOLOGIES

📌 Contact Person: Deepanshu Saxena

📞 WhatsApp/ Mobile: +91-8800622761

🌐 Website: https://coilwinder.in/

📧 Email: [email protected]

Reviews

There are no reviews yet.