Why Automation is Necessary in Relay Coil Manufacturing Today

The relay coil industry is no longer limited to small-scale assembly lines. With the need for millions of coils every month by automotive OEMs, industrial panel manufacturers, and electronic control device makers, automation is not a luxury — it’s a strategic requirement.

Key Drivers for Automation:

- Manpower Dependency: Traditional methods rely heavily on skilled labor, which is inconsistent and expensive.

- Precision Challenges: Manual or semi-automatic winding lacks uniformity in tension, coil turns, and insulation.

- Quality Rejections: Non-standard bobbins, uneven winding, and soldering variations cause high rejection rates.

- High Volume Demand: Large batch production with short lead times is not feasible manually.

- Testing Integration: In-line testing like resistance or inductance measurement is hard to integrate in manual setups.

What Automation Brings:

- Consistent cycle times (20–25 seconds/piece)

- Zero human fatigue or quality variations

- Integrated soldering, taping, testing, and binning

- Real-time monitoring and production logging

- Quick changeover options for different bobbin types

Overview: Relay Coil Production Machine Line Stations

Let’s walk through each automation station in the machine line and understand its function:

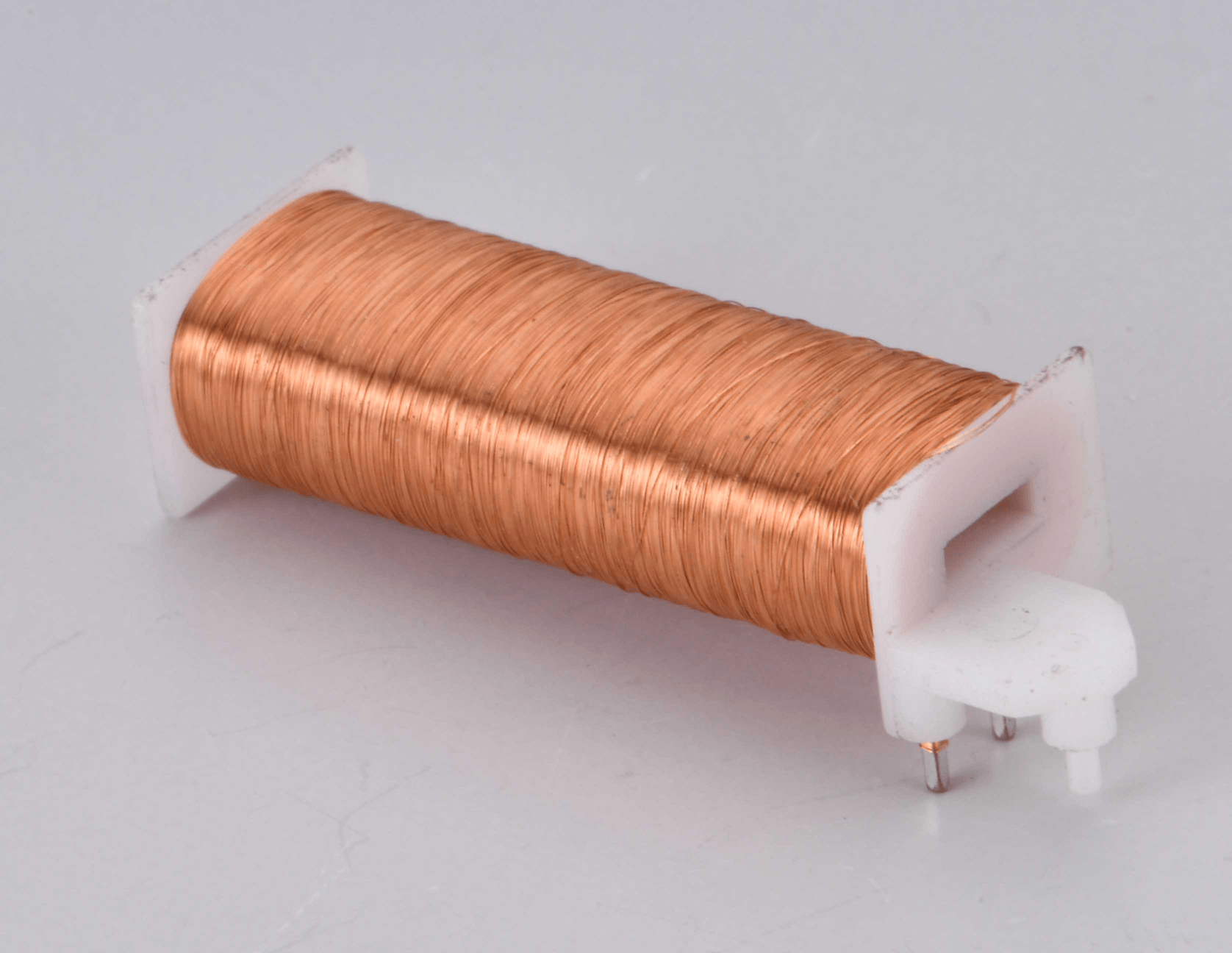

Station 1: Automatic Bobbin Loading via vibrator bowl

- Vibrator bowl-based feeding system

- Picks and orients relay bobbins accurately

- Loads onto indexing conveyor or fixture for next station

This station ensures high-speed, continuous feeding of bobbins through a vibrator bowl. Vibrator bowls are customized according to bobbin dimensions to prevent jamming or misfeeds. Bobbins are aligned and presented consistently to the loading unit, reducing manual intervention.

Station 2: Auto Terminal Pin Insertion into bobbin

Once bobbins are loaded, the system inserts terminal pins with micron-level precision. Pin alignment and insertion force are controlled via pneumatic or servo-actuated systems, depending on client preference.

Highlights:

- Custom jig for each bobbin model

- Pin presence detection system

- Servo or pneumatic punch options

- High precision insertion with camera-guided optional CCD vision check to detect missing or bend pins

Station 3: Auto Loading to Coil Winding Machine

The system auto-loads bobbins to the winding platform using a robotic arm or pick-and-place mechanism. The machine accommodates multiple bobbins at a time for simultaneous winding.

- Transfers prepared bobbins to a multi-spindle winding head

- Reduces cycle time dramatically

- Ensures consistent loading position

- Integrates seamlessly with the winding station

- Precise chuck clamping with auto alignment

- Smooth transition to winding stage

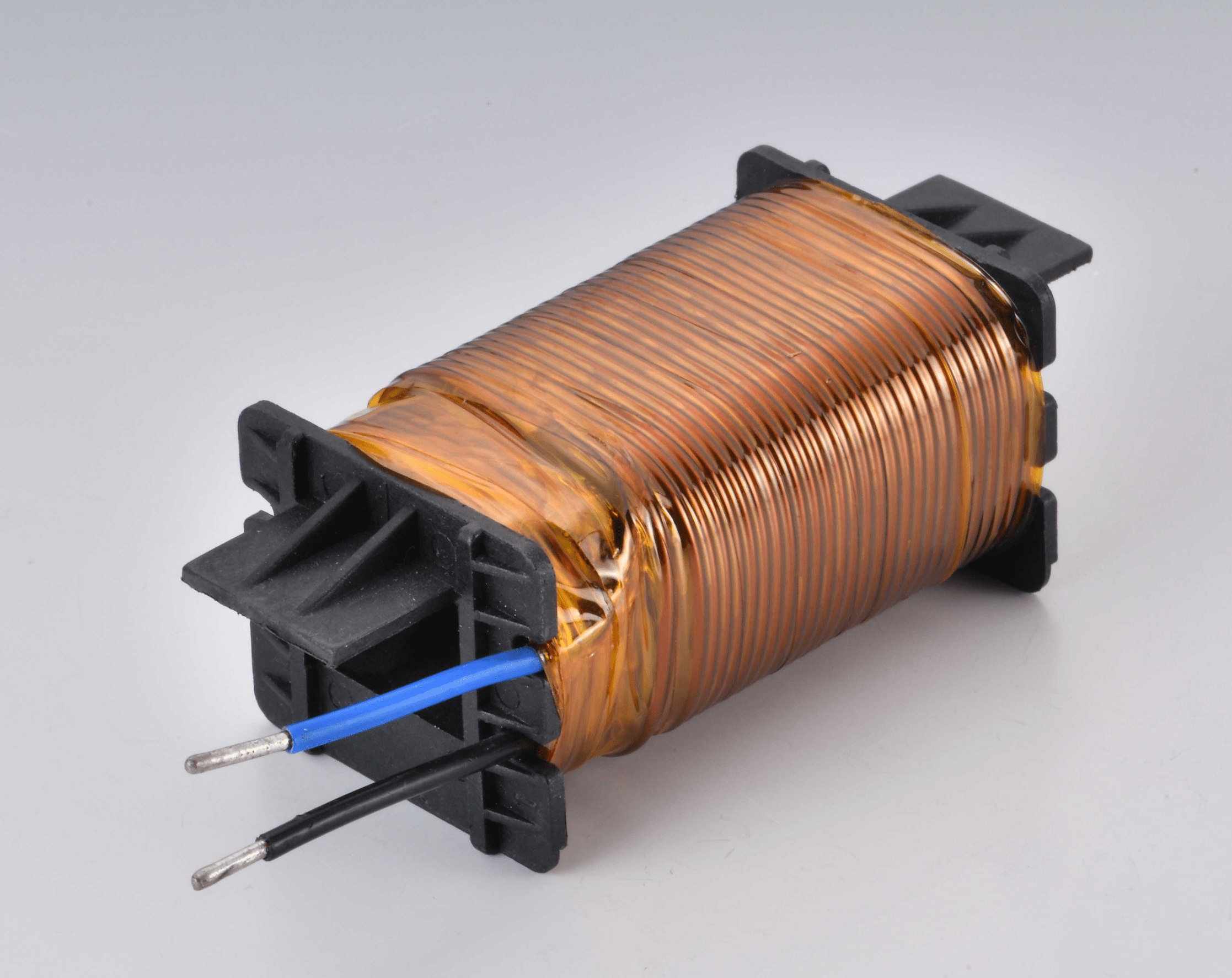

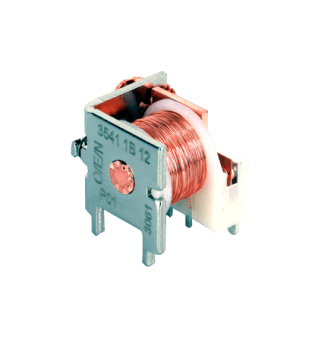

Station 4: Automatic Relay Bobbin Winding (12 Spindles)

This is the core process. Each spindle is equipped with a motorized drive that supports high-speed winding. Features include polyester tape wrapping, optional copper wire twisting for ultra-thin wires, and magnetic or servo tension control.

- 12/16/20/24 bobbins wound simultaneously (different machine models)

- Cycle Time: 20–25 seconds (depends on winding turns & bobbin complexity)

- Wire diameter: 0.04mm to 0.40mm (thin gauge winding also supported)

- Optional wire twisting unit (twister) for fine wires

- Servo or magnetic tensioners for tension control

- Programmable winding turns

- Optional polyester taping unit integrated inline

Station 5: Auto Unload from Winding and Load to Soldering station

Completed wound bobbins are unloaded and immediately transferred to the soldering unit. This system minimizes idle time between stations.

- Process: Wound bobbins are unloaded and placed accurately into the next station.

- Mechanism: Robotic pick-and-place system

- Integration: Synchronization with winding and soldering stations ensures zero downtime.

Station 6: Dip Soldering or Spot Welding (As per Client Requirement)

As per customer requirements, there are options can provided :

A). Dip Soldering:

- Auto flux dip, solder dip

- High-precision temperature control

- Temperature and dwell time programmable

B). Spot Welding:

- Contactless bonding

- Precision fusion technique for high-reliability coils

- Enhanced for automotive or defense-grade relays

Station 7: Auto Testing – via Resistance or LCR Meter

The system verifies the electrical performance of each relay coil using an integrated tester:

- Resistance or inductance measurement through LCR meter

- Pass/Fail logic with threshold setting

- Integrated database logging of values (optional)

Testing Options:

- Resistance check

- LCR (Inductance/Capacitance/Resistance)

- Auto OK/NG classification

Station 8: Automatic Sorting to Tray / Conveyor / Bin

Based on client’s plant layout and workflow, components are auto-unloaded to trays, conveyors, or customized bins.

- Flexibility Includes:

- Stackable trays

- Anti-static bins

- Inline transfer conveyors

- Based on test result, good coils go to tray or conveyor

- NG coils rejected automatically into separate bin

Station 9: Optional Riveting or Assembly Process

If clients need the final assembly to include terminal riveting, Deptronics offers a mechanical or servo-driven riveting station.

- Pneumatic riveting tool to secure core or cover

- Optional customization based on relay design

Station 10: CCD Visual Inspection (Optional)

A high-resolution CCD camera system is installed for visual defect inspection like:

- Vision inspection system

- Checks pin positions, winding quality, or tape overlap

- Loose wire

- Misaligned solder points

- Enables real-time image-based quality checks.

Station 11: Good / NG Piece Separation

Based on results from the test and CCD station, the line automatically segregates defective and good units.

Safety Systems:

- Reject bin for NG parts

- Pneumatic pusher or robotic diverter

- Reduces risk of human error in sorting

Station 12: Final Unloading to Packing / Tray / Box

The final qualified relay coils are automatically unloaded to the final packaging tray or bulk tray.

Client Options:

- Pick and place to final packaging tray or box

- Barcode labeling for finished parts

- Stack counting and batching supported

- Anti-static trays or boxes optionally integrated

Video Demonstration of the Machine :

Key Features of the Relay Coil Production Line :

- Fully Automatic Line: Eliminates manual steps for bobbin handling, pin insertion, winding, soldering, and unloading.

- 12-Spindle Winding System: Simultaneous production for higher output.

- Robotic Handling: Intelligent arms for loading/unloading, reducing human error.

- Modular Architecture: Easy upgrades or replacements.

- Smart Testing & CCD Inspection: Fault detection with precision.

- Compact Footprint: Space-saving layout suitable for Indian factories.

- Custom Trays & Bins: For easy downstream integration.

- Interoperable with MES: Industry 4.0 ready, supports smart factories.

Technical Specifications

| Feature | Description |

| Bobbin Size Range | Custom as per client’s design |

| Winding Heads | 12/16/20/24 Spindles |

| Wire Type | Copper (UEW, PEW), 0.04–0.40mm |

| Tension Control | Magnetic/Servo (optional) |

| Pin Insertion | Pneumatic/Servo with jig |

| Soldering | Dip soldering / Spot welding (optional) |

| Test System | Resistance or LCR |

| Vision System | Optional CCD for defect inspection |

| Output Capacity | Up to 10,000 pcs/day |

| Power Requirement | Single Phase, 230V, 50Hz |

| Air Requirement | 0.4–0.6 MPa |

| Control Panel | PLC-based with HMI Touchscreen |

Benefits to Clients

- Cost Savings: Reduced labor and minimal rework lead to direct savings.

- Faster Production: Shrinks cycle time and increases output.

- Consistent Quality: Precision machines lower defect rates.

- Scalability: Easily upgradeable to 24-spindle or integrate with packaging.

- Reputation Boost: Reliable delivery improves your market credibility.

ROI & Production Cost Analysis

The return on investment for this automated line is typically within 10–14 months, based on a two-shift operation.

Example Projection:

- Manual Labor Cost: ₹1.5 lakh/month

- Defect/Rework Losses: ₹30,000/month

- Automated Line Output: 3x more than manual process

ROI Factors:

- Lower labor dependence

- Lower maintenance cost

- Zero idle time between stations

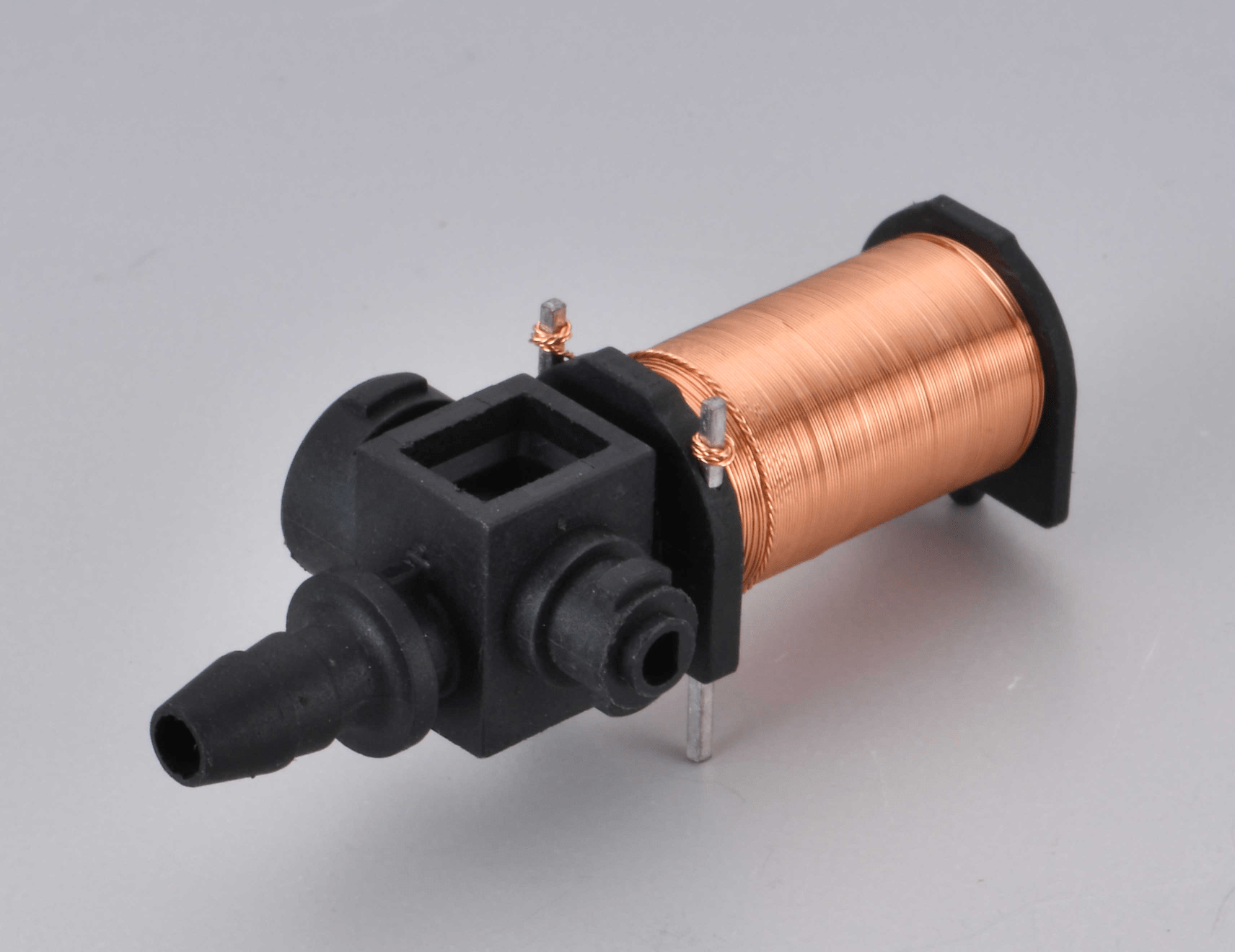

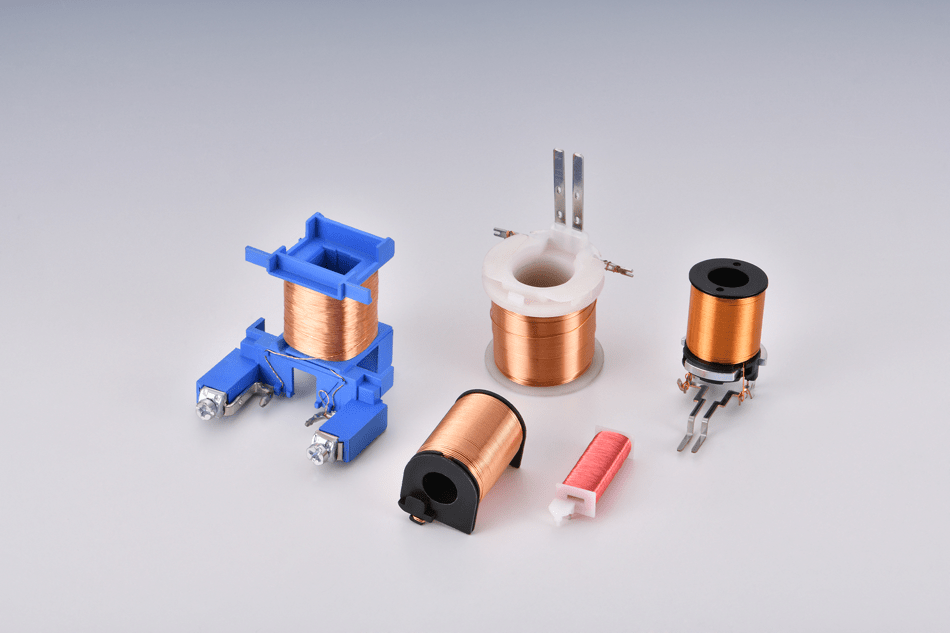

Industry Applications

Relay coils manufactured using this line are used in:

- Automotive Relays

- Power Relays

- PCB Relays

- Signal & Communication Relays

- Smart Home Systems

- Industrial Automation Panels

Why Choose Deptronics Technologies?

Deptronics Technologies stands out in India as the most trusted brand for fully automatic coil winding, soldering, and assembly machines.

We Offer:

- Complete installation & commissioning

- On-site training for operators

- Responsible after-sales service

- Spare parts availability

- AMC (Annual Maintenance Contracts)

- Online support through WhatsApp, video, and audio call

- Customization options for each client requirement

Whether you are just beginning automation or expanding your factory’s output — Deptronics ensures full technical partnership.

Automatic Machine Production Line for Relay Coil Manufacturing in India

Final Words

Relay coil production is shifting towards automation rapidly. The manufacturers who adopt advanced machine lines like the one offered by Deptronics Technologies will be the ones who lead the market in speed, quality, and consistency.

If your business requires high-volume relay coil production with maximum yield, minimum labor, and long-term savings — investing in this 12-station relay coil production line is the smartest move.

Let Deptronics be your technology partner, not just a machine vendor.

Frequently Asked Questions (FAQs)

Q1. Can this machine be customized for different bobbins?

Yes. Each machine is designed according to your bobbin size, terminal layout, and winding specification. Interchangeable tooling and mandrels are optional.

Q2. What wire size range is supported?

Typically from 0.04mm to 0.40mm, depending on relay design.

Q3. Is after-sales support available pan India?

Yes. Deptronics provides service engineers across India with online and physical support.

Q4. What are the options for testing?

Resistance test and LCR measurement can be integrated into the machine.

Q5. Is taping or twisting required in all relays?

Not always. But if required, optional polyester tape wrapper and copper twister modules are available.

For product inquiries, pricing, or customization options, contact Deptronics Technologies today!

📞 Contact Us: DEPTRONICS TECHNOLOGIES

📌 Contact Person: Deepanshu Saxena

📞 WhatsApp/ Mobile: +91-8800622761

🌐 Website: https://coilwinder.in/

📧 Email: [email protected]

For mass production of solenoid coils, check our “Solenoid Coil Automatic Production Line for Mass Manufacturing”

Fully Autopilot Machine Line for Solenoid Valve Coil Manufacturing

Santosh Mishra –

we already have this automation line for relay coil in delhi, they are very professional and machine quality is also satisfactory, suitable for bulk production.