Machine Overview

The Fully Automatic Common Mode Choke Coil Production Line is a turnkey solution designed to manufacture choke coils at scale. Built for UU10.5 and UU9.8 bobbin sizes, it integrates multiple machines into one streamlined production line where every step, from raw material feeding to final quality testing, is automated.

Key Highlights:

- Auto bobbin feeding and orientation through vibrator bowl

- High-speed 12 spindle winding machine for parallel production

- In-line taping, soldering, and flux dipping for precision connections

- Automated core feeding, assembly, and grinding

- Auto metal clip feeding and assembly

- Built-in auto testing and laser marking for traceability

- Smart unloading into trays, ready for packing

By eliminating human handling in sensitive processes like winding, soldering, and core assembly, the machine ensures uniformity in coil performance and reduces rejection rates.

This line is designed for high-volume manufacturers who require consistent production quality while keeping costs under control.

Step-by-Step Working Process

To understand the true value of this line, let’s break down the process flow:

1. Auto Bobbin Feeding through Vibrator Bowl

The line begins with an automatic vibrator bowl feeder. Bobbins are randomly poured into the bowl and are aligned in the correct orientation. This removes the need for operators to manually place bobbins on spindles, ensuring uninterrupted and continuous production.

2. Auto Bobbin Loading to 12 Spindle Winding Machine

The aligned bobbins are loaded directly onto the 12 spindle winding machine. This unique design enables 12 bobbins to be wound simultaneously in one cycle, drastically increasing productivity compared to single-spindle or semi-automatic setups.

3. Automatic Winding & Taping (12 pcs in one cycle)

The machine performs precision-controlled copper wire winding according to pre-programmed specifications. Wire tension, turns count, and layering are monitored by a closed-loop system, eliminating human error.

Immediately after winding, taping is applied automatically to secure the coil windings. This ensures insulation reliability and saves time compared to manual taping operations.

4. Unload from Winding Machine and Load to Soldering Station

Once winding and taping are complete, the machine automatically unloads the bobbins and transfers them to the soldering station without human intervention.

5. Flux Dipping & Dip Soldering

At this stage, lead wires are dipped in flux and soldered automatically in a controlled environment. Automated soldering ensures:

- Correct solder volume

- Uniform joint strength

- Zero cold solder issues

This process guarantees strong, reliable electrical connections for every coil.

6. Auto Load to Core Assembly Machine

After soldering, coils are transferred to the core assembly station.

7. Auto Core Feeding through Vibrator Bowls

Just like bobbins, cores are also fed through vibrator bowls. The machine automatically orients and positions the cores for accurate assembly.

8. Core Assembly

The machine inserts the ferrite cores into the wound bobbins with high precision. Proper core alignment is crucial for maintaining consistent inductance values across all coils.

9. Core Grinding

After assembly, the cores undergo grinding to achieve flatness and remove excess burrs. This ensures proper surface contact and improves magnetic efficiency.

10. Metal Clip Auto Feeding

To secure the core assembly, metal clips are automatically fed into the workstation.

11. Auto Metal Clip Assembly

The machine presses the clips onto the cores, ensuring secure fastening without damaging the components.

12. Auto Testing

Each finished choke coil is subjected to automatic electrical testing using an in-built LCR meter. Parameters like inductance, resistance, and leakage are verified to meet customer specifications. Any defective piece is automatically rejected.

13. Laser Marking

For traceability, the machine performs laser marking on each approved coil. Manufacturers can include batch codes, dates, or logos for quality control.

14. Final Unloading into Tray

Finally, the tested and marked coils are unloaded into trays in an organized manner, ready for packaging or direct assembly into client products.

This end-to-end automation ensures seamless production flow without manual dependency.

Video Demonstration :

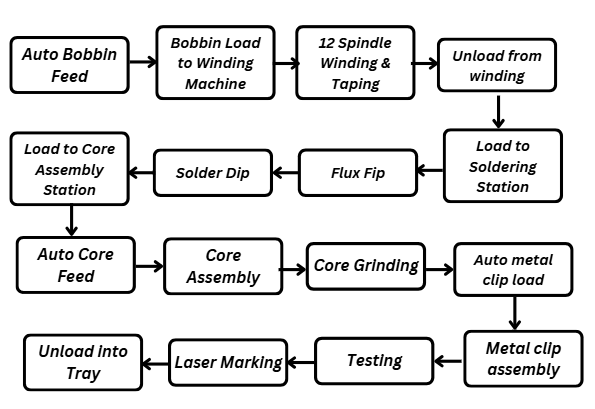

Flow Chart of complete machine operation

ROI & Productivity Analysis

One of the biggest questions for manufacturers is always Return on Investment (ROI). Let’s break it down:

-

Cycle Time: 35–40 seconds per set of 12 coils

-

Production per Hour: ~1,080 to 1,200 coils

-

Production per 8-Hour Shift: ~8,500 to 9,500 coils

-

Production per Month (25 days): ~2,12,000 coils

ROI Benefits:

-

Manpower reduction: Replaces multiple operators across winding, soldering, and assembly stages

-

Consistency: Near-zero rejection rate compared to manual processes

-

Energy efficient: Optimized power usage compared to semi-auto setups

-

Payback period: Typically within 12–18 months depending on production volume

Who Should Use This Machine Line?

This production line is ideal for:

-

Mass Production Manufacturers who need high volumes daily

-

Electronics & Power Supply Companies producing adapters, chargers, inverters

-

Automotive Electronics Industry, especially EV component manufacturers

-

OEMs & EMS Companies requiring bulk choke coil production

-

Component Manufacturers catering to global markets

If your company aims to scale production while maintaining world-class quality, this machine line is the right investment.

Client Benefits

When you invest in this fully automatic line, you gain:

-

High productivity (12 coils per cycle)

-

Consistent quality output

-

Reduced manpower dependency

-

Faster delivery to your customers

-

Competitive edge in domestic & export markets

-

In-line testing & traceability reduces risk of faulty shipments

Deptronics as Your Automation Partner

At Deptronics Technologies, we don’t just supply machines – we provide complete automation solutions.

-

Trusted OEM Partnership: We are official partners of our principal Diggers (China), a global leader in coil winding automation.

-

Local Support in India: Installation, commissioning, and operator training at your factory.

-

Spare Parts Availability: Quick access to consumables and critical components.

-

After-Sales Service: Dedicated Indian team for troubleshooting and support.

Why Choose Deptronics Technologies?

-

Experience: Trusted by leading manufacturers in India

-

Innovation: Access to the latest global technology in winding and automation

-

Reliability: Strong after-sales service and long-term customer relationships

-

Transparency: Clear communication, no hidden costs

-

Customer-Centric Approach: Tailored solutions to match your exact production needs

With Deptronics, you get global technology with local support.

Fully Automatic Common Mode Choke Coil Production Machine Line | UU10.5 UU9.8 India Manufacturer

Key Takeaways

The future of common mode choke coil manufacturing in India is automation. Manual or semi-automatic production can no longer match the rising demand for precision, speed, and quality.

The Fully Automatic Common Mode Choke Coil Production Machine Line for UU10.5 and UU9.8 models ensures your business is ready for the future. With cycle times of just 35–40 seconds, in-line testing, and auto-marking, it not only improves your production capacity but also enhances your brand reputation with consistent quality.

By partnering with Deptronics Technologies, you gain more than a machine – you gain a dedicated automation partner committed to your growth.

👉 If you are ready to upgrade your production line and take your manufacturing business to the next level, contact Deptronics Technologies today.

For machine inquiries, pricing, or customization options, contact Deptronics Technologies today!

DEPTRONICS TECHNOLOGIES

📌 Contact Person: Deepanshu Saxena

📞 WhatsApp/ Mobile: +91-8800622761

🌐 Website: https://coilwinder.in/

📧 Email: [email protected]

Automatic Machine Production Line for Relay Coil Manufacturing in India

Reviews

There are no reviews yet.