Why the Industry Is Moving Toward Automatic Winding Machines

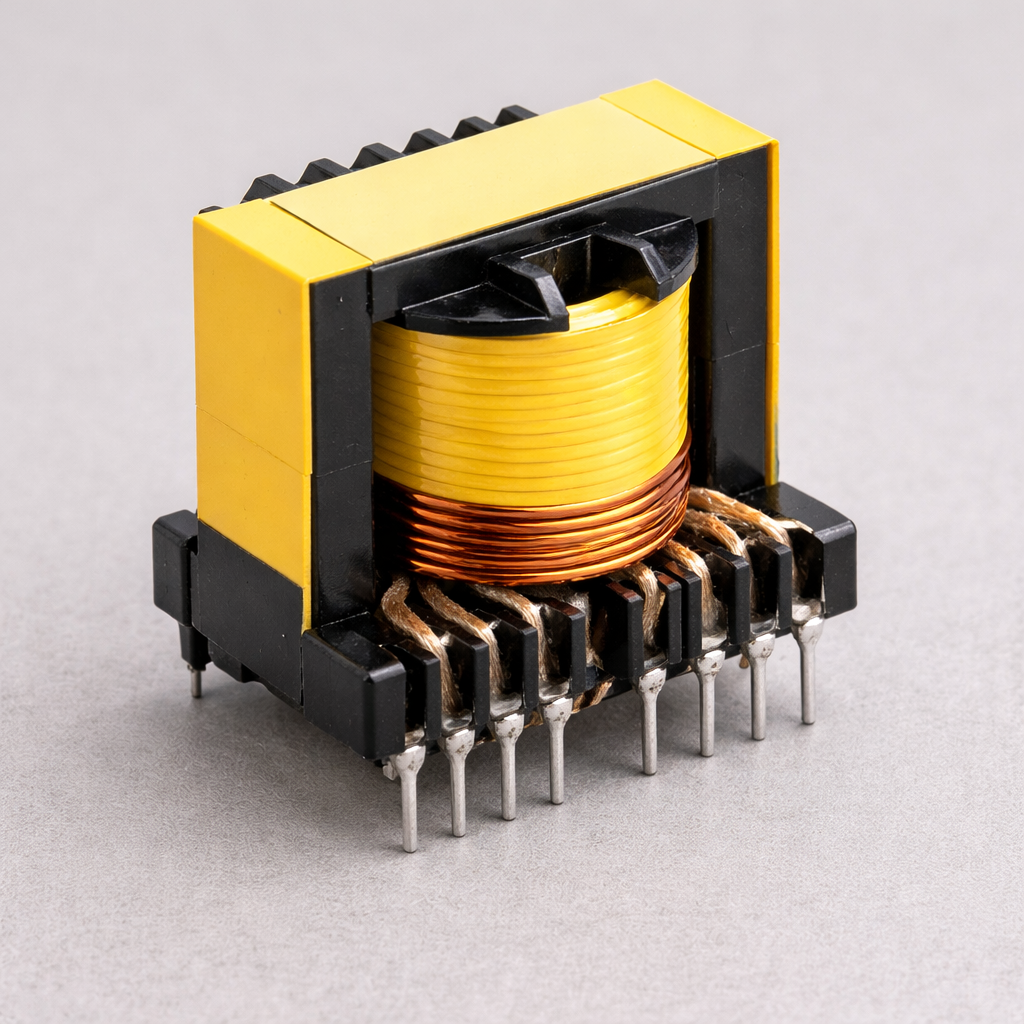

Rising Complexity of SMPS Transformers

Modern SMPS transformers involve:

- Multiple windings (primary, secondary, auxiliary)

- Parallel wires to reduce skin effect and copper losses

- Multiple insulation sleeves to meet safety creepage and clearance norms

- Tight dimensional tolerances for compact power supply designs

Such complexity makes manual winding highly inconsistent and risky.

Demand for Consistency and Compliance

OEMs supplying to automotive, medical, telecom, and export markets must comply with:

- Hi‑pot and insulation resistance standards

- Thermal endurance requirements

- Repeatable electrical performance across large batches

Automatic winding machines eliminate operator variability and ensure consistent results.

Cost and Productivity Pressures

With rising labor costs and skilled manpower shortages, automation offers:

- Higher output per shift

- Lower dependency on highly skilled operators

- Reduced rejection and rework costs

Overview of the Automatic Winding Solution for Ferrite SMPS Transformers

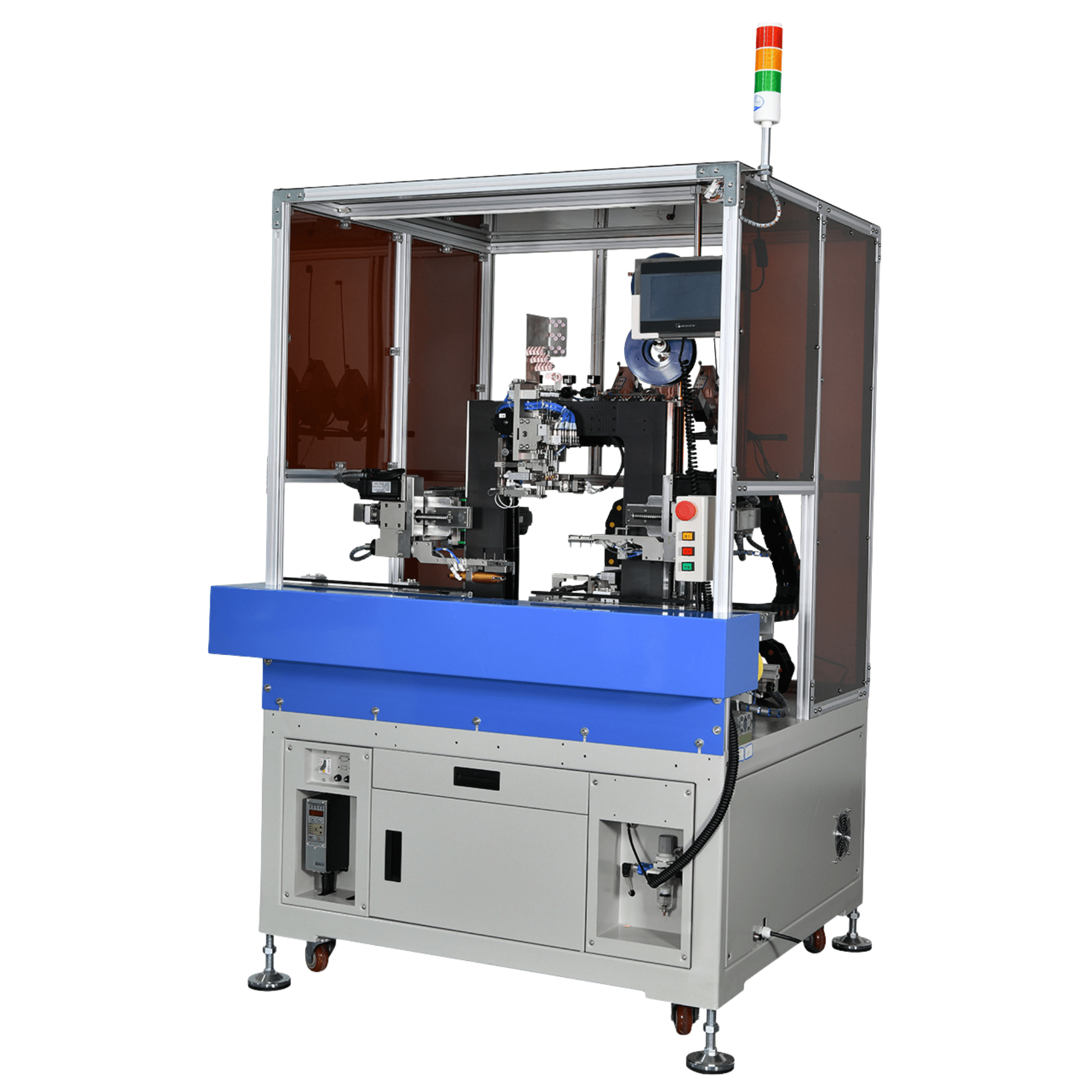

The Double ARM | 3 Wire 3 Sleeve SMPS Transformer Winding Machine is a fully automatic system engineered to perform complex transformer winding operations in a single, continuous cycle.

Key highlights include:

- Double‑arm synchronized winding mechanism

- Simultaneous winding of up to three parallel wires

- Automatic insertion of up to three insulation sleeves

- Recipe‑based control for different transformer models

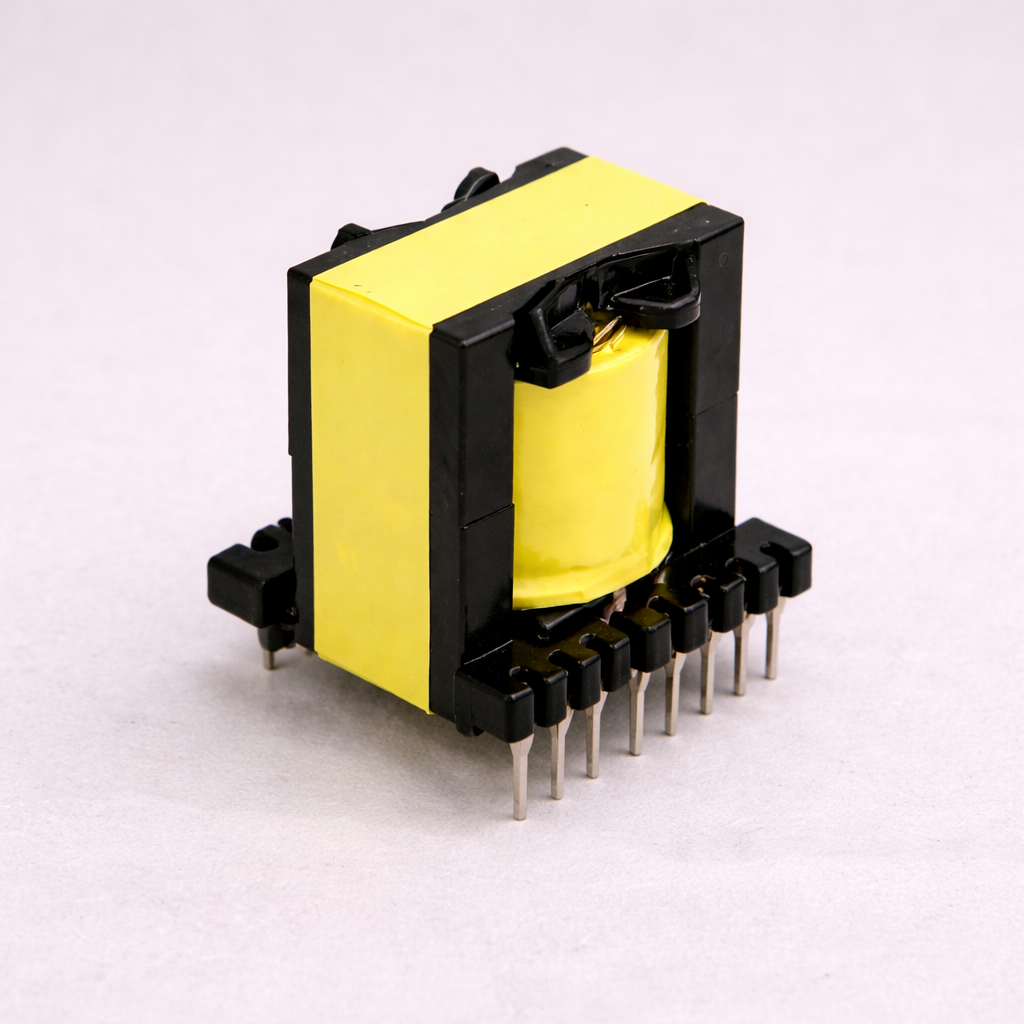

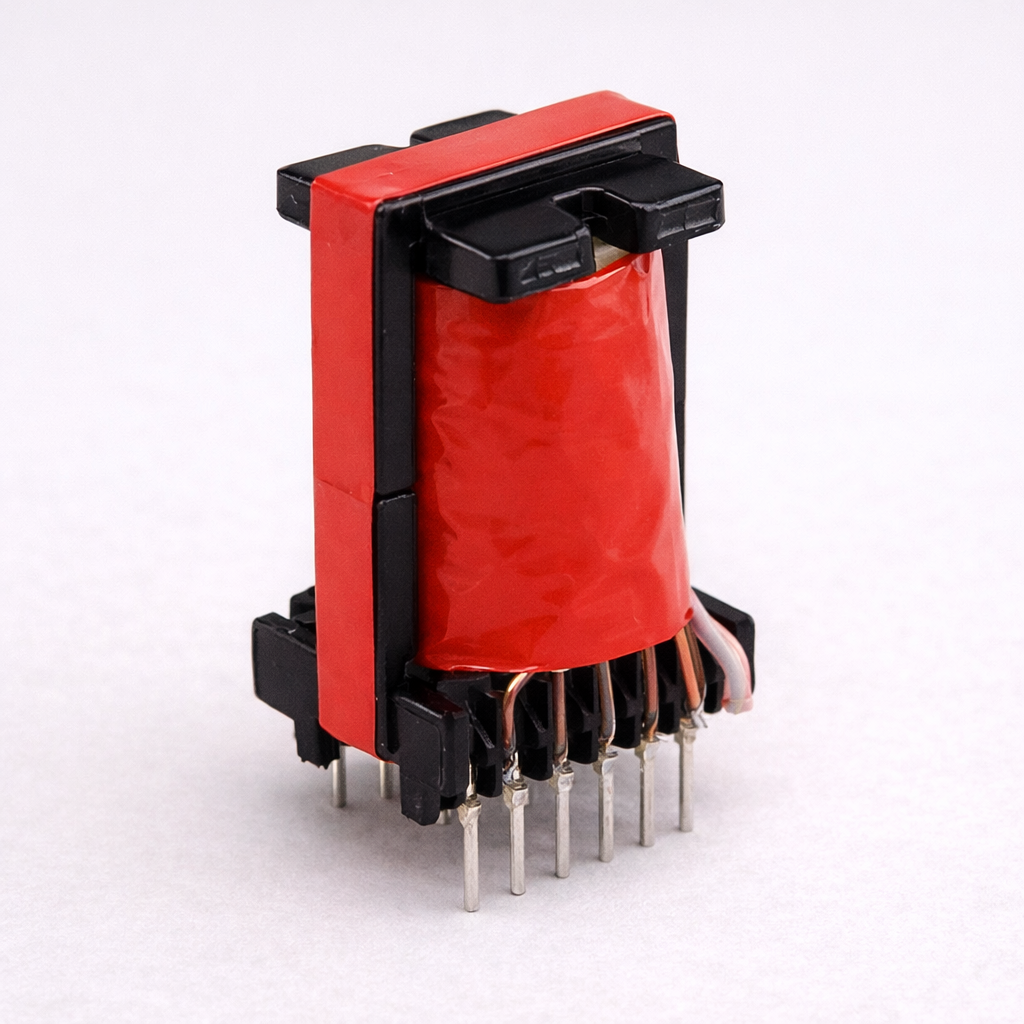

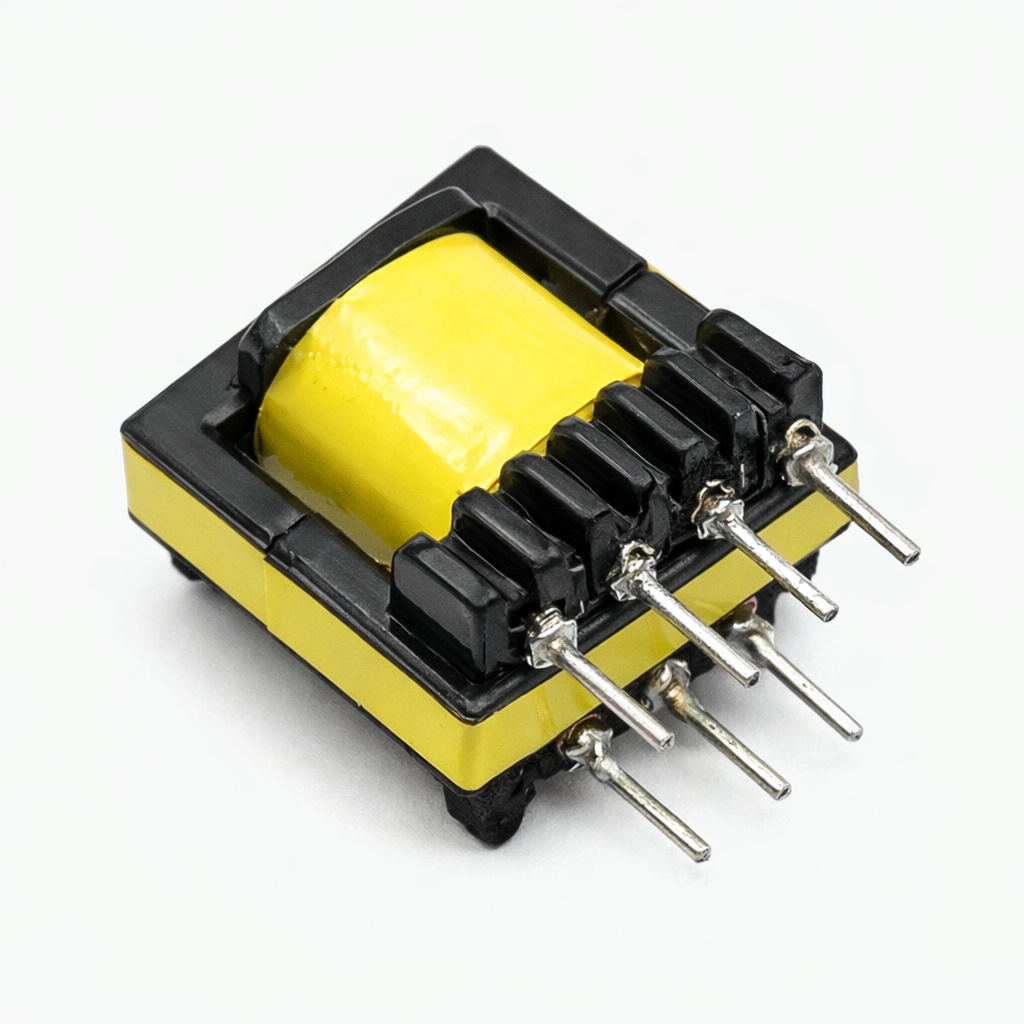

The machine is suitable for ferrite core transformers such as EE, EER, EFD, ETD, PQ, RM, and ER series, commonly used in SMPS applications.

Machine Working Video: Practical Understanding

Machine Operation: How the Double ARM System Works

At the core of this machine’s performance is its dual synchronized robotic arm system. Both arms work in parallel to execute complex winding sequences with exceptional speed and precision.

Typical Transformer Winding Cycle

- Automatic Bobbin Loading

The empty bobbin is automatically loaded into the winding fixture. - First Winding Operation

Required wire(s) are picked, the programmed sleeve is inserted, winding is completed, and tape is applied. - Second Winding Operation

A different wire and sleeve combination is selected automatically, followed by winding and taping. - Third & Fourth Windings (If Required)

The same automated process is repeated as per the winding program. - Automatic Unloading

The finished transformer bobbin is ejected or transferred to the next station via tray or conveyor.

The system can handle up to four wires and three sleeve sizes, making it ideal for transformers with complex internal structures.

Step-by-Step Operational Breakdown

1. Bobbin Loading

- Manual loading or optional auto-loader

- Fixture supports single or multi-bobbin configurations

2. Program Selection

- Operator selects the required transformer model via HMI

- Programs are pre-configured based on winding data

3. Simultaneous Dual ARM Winding

Both ARMs operate synchronously to complete:

- Primary winding

- Secondary winding

- Feedback winding

- Auxiliary winding

Supported winding types include:

- Layer winding

- Bifilar / Trifilar winding

- Interleaved winding

- Section winding

- Tap winding

4. Multi-Axis Servo Control

- Up to 14-axis servo coordination

- Perfect control over tension, traverse, and alignment

- High-torque motors maintain speed even with thick or bunch wires

5. Integrated Automation Modules

- Automatic wire cutting & holding

- Sleeving unit for insulation insertion

- Taping unit for layer insulation

- Automatic unloading to tray or conveyor

Technical Specifications (Typical Configuration)

| Feature | Specification |

|---|---|

| Winding Arms | 2 (Independent & Synchronized Double ARM) |

| Axis Control | 14-Axis Servo Control System |

| Max Bobbin Size | Up to PQ40 (custom bobbins supported) |

| Wire Diameter Range | 0.03 mm – 1.2 mm |

| Wire Types Supported | Enameled Copper, Litz Wire, Bifilar, Trifilar, Bunch Winding |

| Parallel Wire Capability | 2–4 wires simultaneously |

| Sleeve Handling | Up to 3 different sleeve sizes per cycle |

| Tension Control | Programmable Digital Tensioners (Individual per wire) |

| Winding Speed | Up to 12,000 RPM (application dependent) |

| Control Interface | 7” or 10” Industrial Touchscreen HMI |

| Program Storage | 50+ winding programs (expandable) |

| Communication | USB, Ethernet, Optional Wi‑Fi |

| Power Supply | 230V / 50Hz / Single Phase |

| Pneumatic Supply | 5–6 bar clean, dry air |

| Safety System | Emergency Stop, Full Guarding & Interlocks |

Core Machine Features

Double Robotic ARM Architecture

The machine is equipped with two high-precision robotic winding arms driven by a 14-axis servo motion system. Both arms operate simultaneously, ensuring fast cycle times while maintaining perfect synchronization and accuracy.

Multi-Wire Handling Capability

Supports 2 to 4 wires at a time, including:

- Parallel winding

- Bifilar / Trifilar winding

- Bunch winding for high-current SMPS transformers

Multi-Sleeve Automatic Insertion

The integrated sleeve insertion unit automatically handles up to three different sleeve sizes during a single winding cycle, eliminating manual insulation handling and ensuring consistent dielectric strength.

Programmable Touchscreen Interface

An intuitive HMI allows operators to:

- Store and recall multiple winding programs

- Adjust winding parameters

- Monitor alarms and production status

Automatic Taping System

Tape is applied automatically after each winding stage, ensuring reliable layer insulation and preparation for core assembly.

Auto Load & Auto Unload

Automated bobbin loading and unloading significantly reduce manual handling, improve safety, and increase overall production speed.

Precision & Consistency

Servo-controlled arms maintain exact wire tension, traverse accuracy, and layer alignment, delivering repeatable results across long production runs.

Machine Architecture & Workflow Design

Double ARM Mechanical Architecture

The double‑arm structure allows two winding arms to operate in a coordinated manner, resulting in:

- Faster cycle times

- Better wire lay consistency

- Balanced mechanical stress

3 Wire Parallel Winding System

Each wire feeder is equipped with:

- Independent tensioners

- Wire break detection

- Precision guides

This ensures equal current sharing and uniform winding density—critical for high‑frequency SMPS transformers.

3 Sleeve Automatic Insulation System

The machine supports automatic handling of:

- PTFE sleeves

- Polyester sleeves

- Customized insulation tubes

Sleeve length, position, and sequence are fully programmable, eliminating human error.

Key Technical Features That Define Performance

High‑Resolution Servo Control

Ensures precise turn count, smooth acceleration, and exact positioning even at high speeds.

Intelligent Recipe Management

Multiple transformer models can be stored and recalled instantly, enabling fast changeover with minimal downtime.

Advanced Tension Monitoring

Individual wire tension control prevents wire stretching, breakage, and uneven layering.

Integrated Safety & Error Detection

- Wire break sensors

- Sleeve presence detection

- Emergency stop and safety interlocks

Industries and Manufacturers Who Can Use This Machine

This machine is ideal for:

- SMPS power supply manufacturers

- LED driver manufacturers

- Telecom power system suppliers

- Industrial automation equipment OEMs

- Medical electronics manufacturers

- EV charger and renewable energy system producers

It suits both medium‑scale manufacturers upgrading automation and large OEMs targeting mass production.

Advantages of Using an Automatic SMPS Transformer Winding Machine

- Superior winding consistency

- High insulation reliability

- Reduced rejection and rework

- Lower labor dependency

- Better compliance with international standards

- Professional, repeatable production quality

Production Capacity and Scalability

The Double ARM configuration allows:

- Shorter cycle times per transformer

- Easy scaling by adding parallel machines

- Integration into conveyor‑based production lines

This makes the solution future‑ready for growing production demands.

How to Choose the Right Automation Partner or Manufacturer

When selecting an automation partner, manufacturers should evaluate:

- Proven experience in transformer winding automation

- Ability to customize machines for specific designs

- Long‑term service and spare availability

- Technical support capability (local and remote)

- Understanding of SMPS transformer application requirements

Choosing the right partner ensures not just machine delivery, but long‑term production success.

Why Choose Deptronics Technologies

Deptronics Technologies offers more than just machines—we deliver complete automation solutions for transformer manufacturing.

Our strengths include:

- Deep application knowledge in SMPS and ferrite transformers

- Partnership with advanced global machine manufacturers

- Transparent project coordination

- Strong installation and after‑sales support in India

- Focus on long‑term customer success

We work closely with customers from concept evaluation to stable mass production.

Installation, Training, and After‑Sales Support

Deptronics Technologies provides:

- Pre‑dispatch inspection support

- Installation coordination at customer site

- Operator and maintenance training

- Preventive maintenance guidance

- Ongoing technical support and spare assistance

Our goal is to ensure smooth commissioning and reliable daily operation.

Final Thoughts

The SMPS Transformer Winding Machine – Double ARM | 3 Wire 3 Sleeve is a powerful solution for manufacturers seeking precision, productivity, and scalability. As SMPS designs continue to evolve, investing in advanced winding automation is no longer a luxury—it is a strategic necessity.

With the right machine and the right automation partner, manufacturers can achieve consistent quality, faster growth, and long‑term competitiveness in the global power electronics market.

Frequently Asked Questions (FAQs)

Q1. Can the machine handle different transformer models?

Yes, multiple models can be handled through recipe‑based programming.

Q2. Is customization possible for specific winding designs?

Yes, machine configuration can be customized based on transformer requirements.

Q3. What insulation materials are supported?

PTFE, polyester, and customized sleeves are supported.

Q4. Can this machine be integrated into a full production line?

Absolutely. It can be connected with soldering, taping, and testing machines.

Contact Us

For machine inquiries, pricing, or customization options, contact us today!

DEPTRONICS TECHNOLOGIES

📌 Contact Person: Deepanshu Saxena

📞 WhatsApp/ Mobile: +91-8800622761

🌐 Website: https://coilwinder.in/

📧 Email: [email protected]

For mass production of relay coils, check our “Automatic Production Line for Mass Manufacturing of Relay Coils”

Reviews

There are no reviews yet.