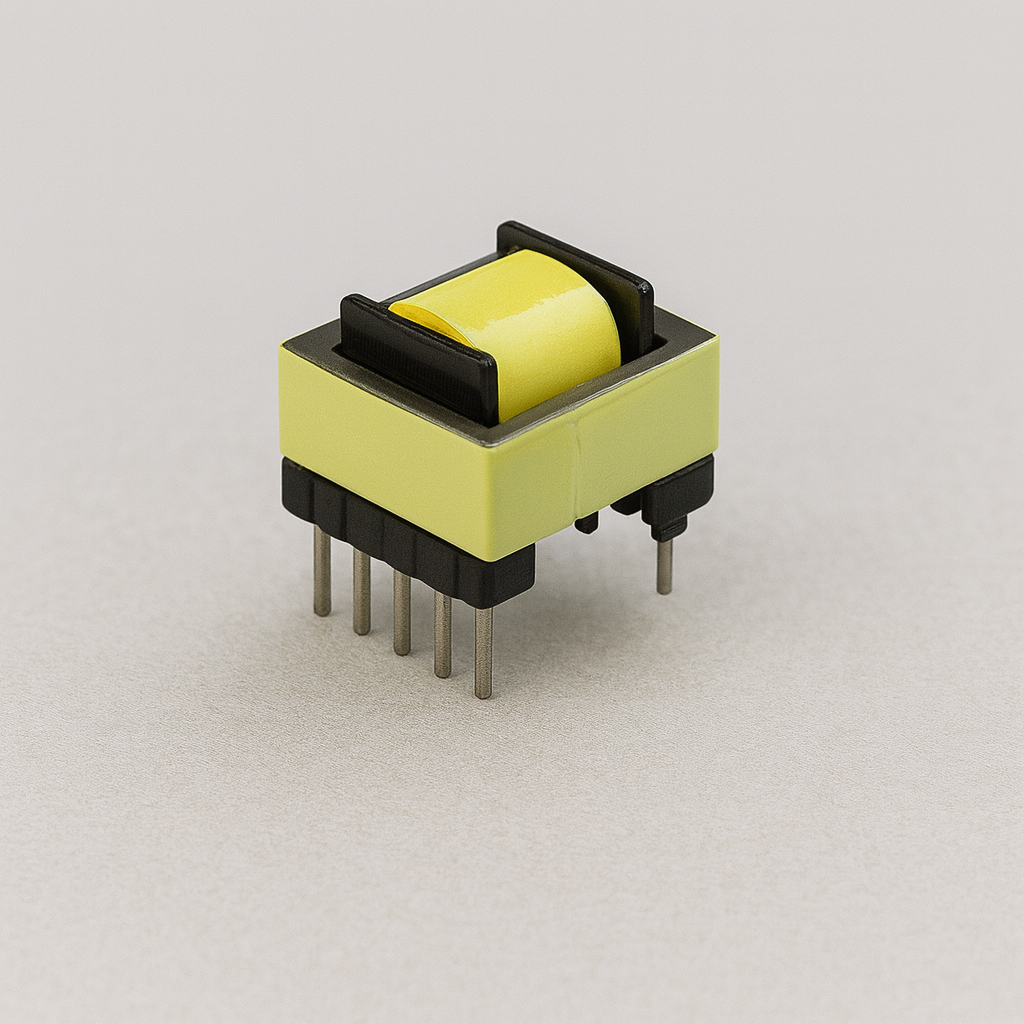

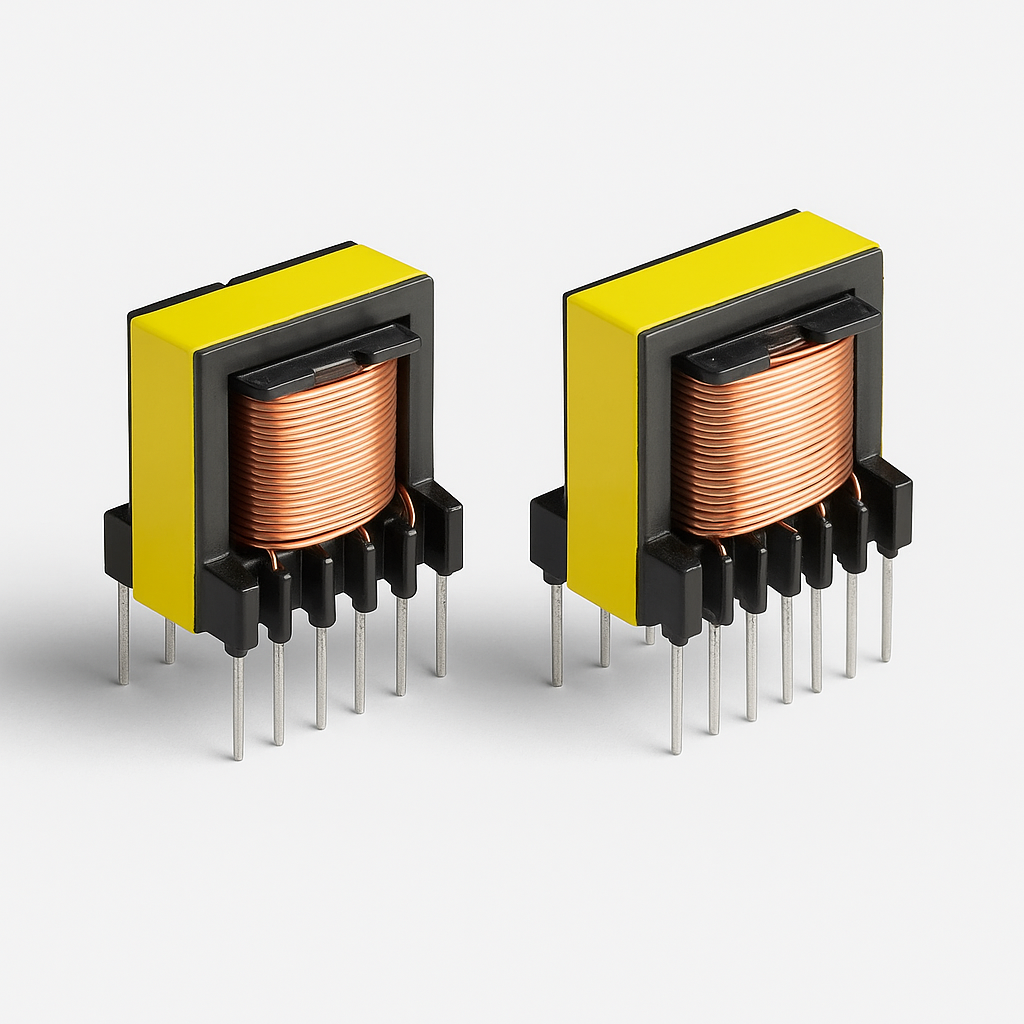

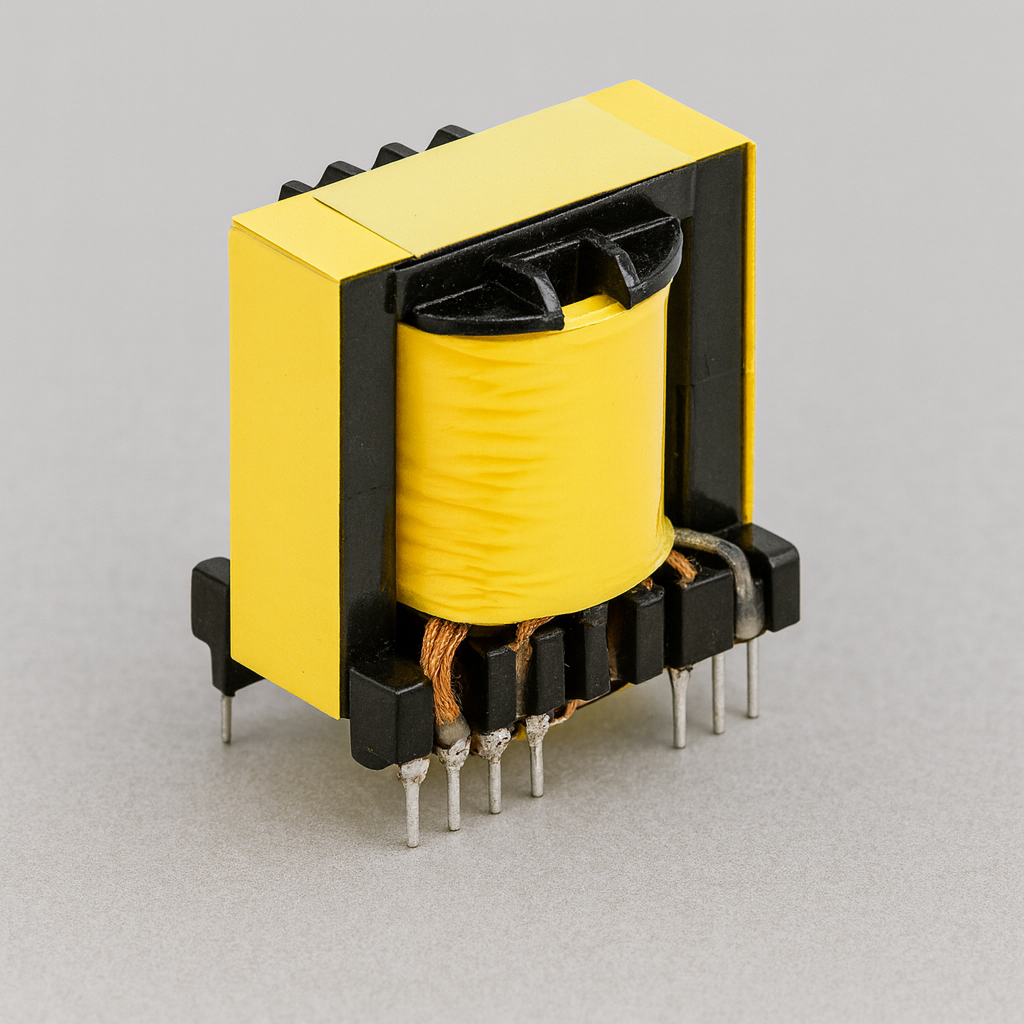

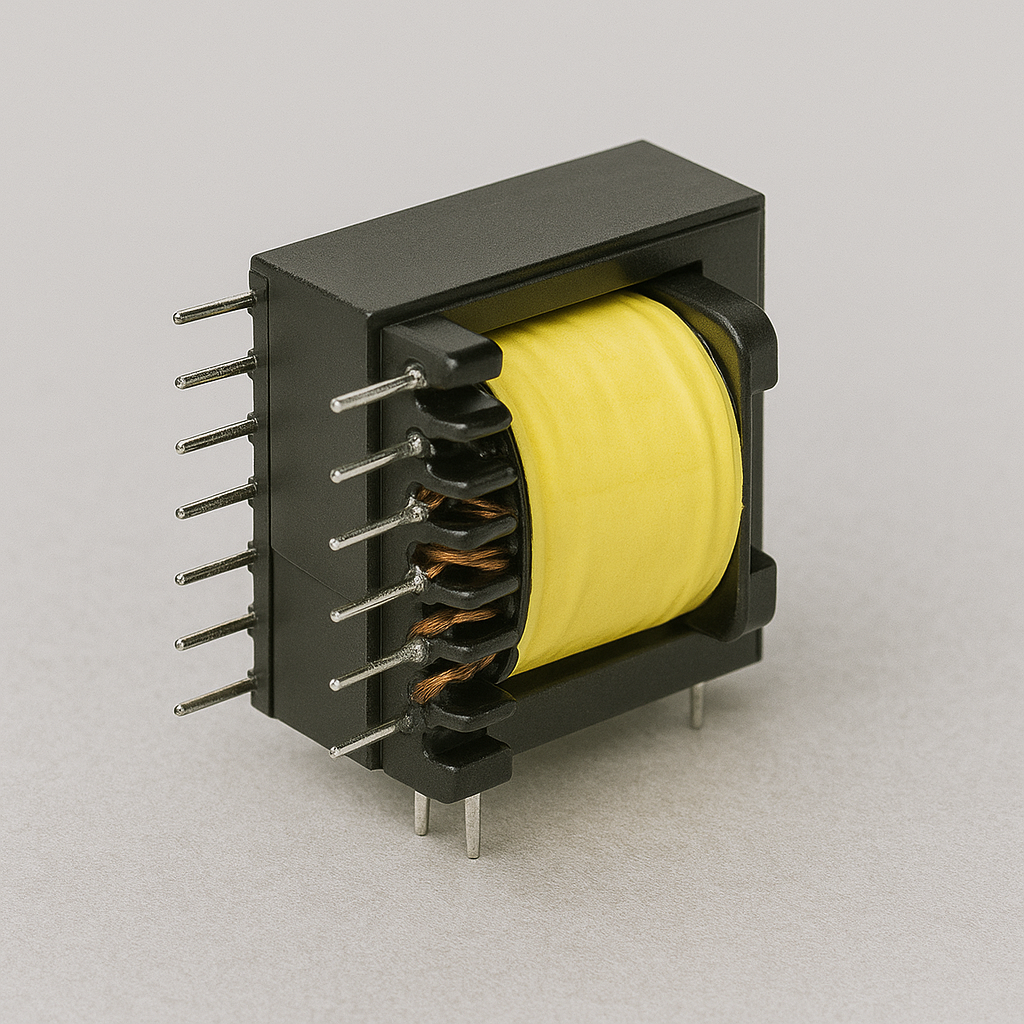

What Is a Ferrite Core SMPS Transformer?

A Ferrite Core SMPS Transformer is a high‑frequency transformer designed to operate typically in the range of tens to hundreds of kilohertz. Unlike conventional laminated iron transformers used at 50/60 Hz, SMPS transformers rely on ferrite cores due to their low core losses at high frequency.

Key characteristics include:

- Ferrite core materials with high magnetic permeability and low eddy current loss

- Compact size and lightweight design

- Multiple windings (primary, secondary, auxiliary)

- Tight insulation and creepage requirements

- High electrical performance consistency

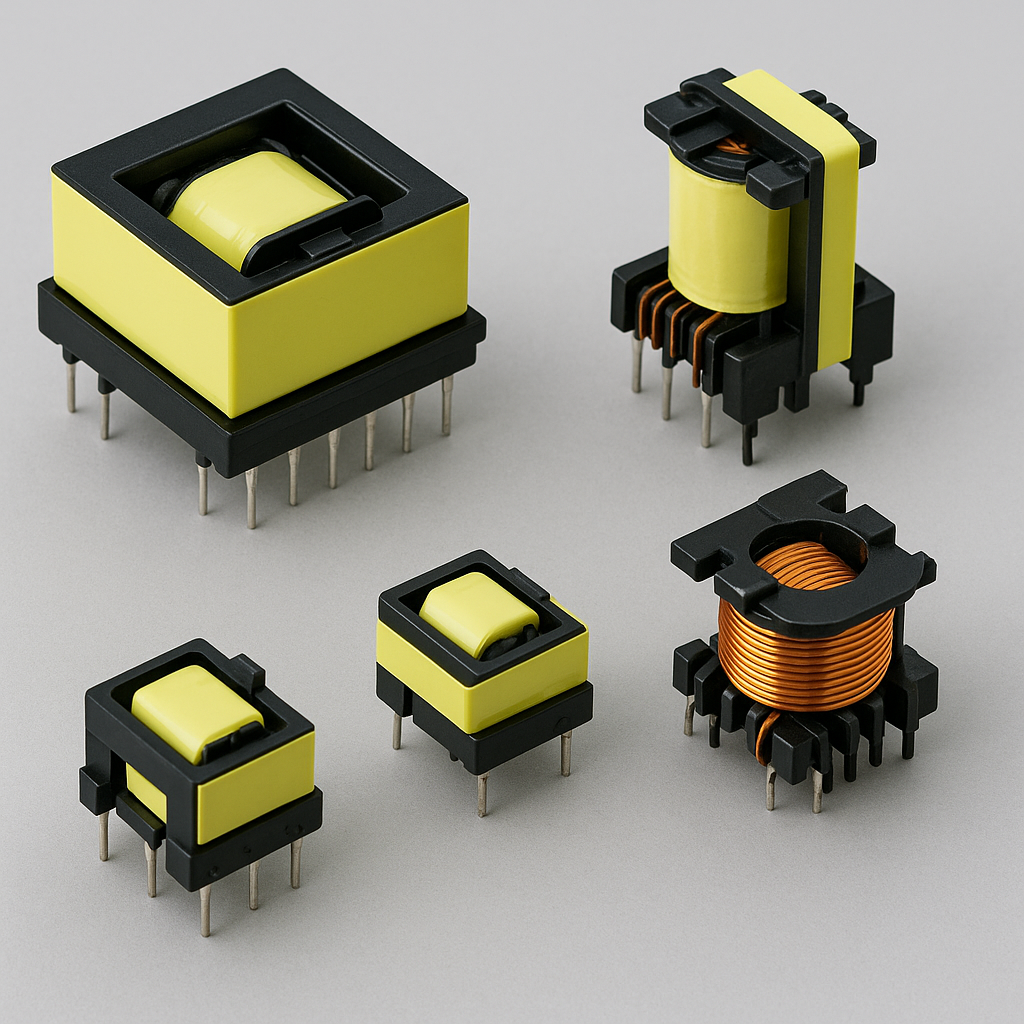

Common ferrite core shapes used in SMPS transformers include EE, EFD, ETD, PQ, RM, and EER cores. Each design demands precise winding tension, accurate turns count, consistent insulation layering, and reliable termination quality.

Because SMPS transformers directly affect power efficiency, EMI performance, and safety compliance, even minor manufacturing variations can lead to product failures. This is the primary reason why automation plays a decisive role in modern transformer manufacturing.

Why the Industry Is Moving Toward Fully Automatic Production Lines

Manufacturers across India and global markets are rapidly adopting fully automatic SMPS transformer production lines due to several converging factors:

1. Rising Production Volumes : OEMs supplying adapters, chargers, power supplies, and inverters operate on tight delivery schedules. Manual production simply cannot scale without compromising quality.

2. Labor Dependency and Skill Variability : Manual winding quality depends heavily on operator skill, fatigue levels, and experience. Automation removes this dependency entirely.

3. Quality Consistency and Traceability : Automatic lines ensure:

- Identical winding parameters for every transformer

- Repeatable insulation placement

- Controlled soldering quality

- Integrated testing and data logging

4. Compliance with Global Standards : Export‑oriented manufacturers must meet IEC, UL, and customer‑specific quality requirements. Inline testing and controlled processes make compliance achievable.

5. Long‑Term Cost Reduction : While the initial investment is higher, fully automatic lines drastically reduce labor cost, rework, rejection, and warranty risks — resulting in faster payback.

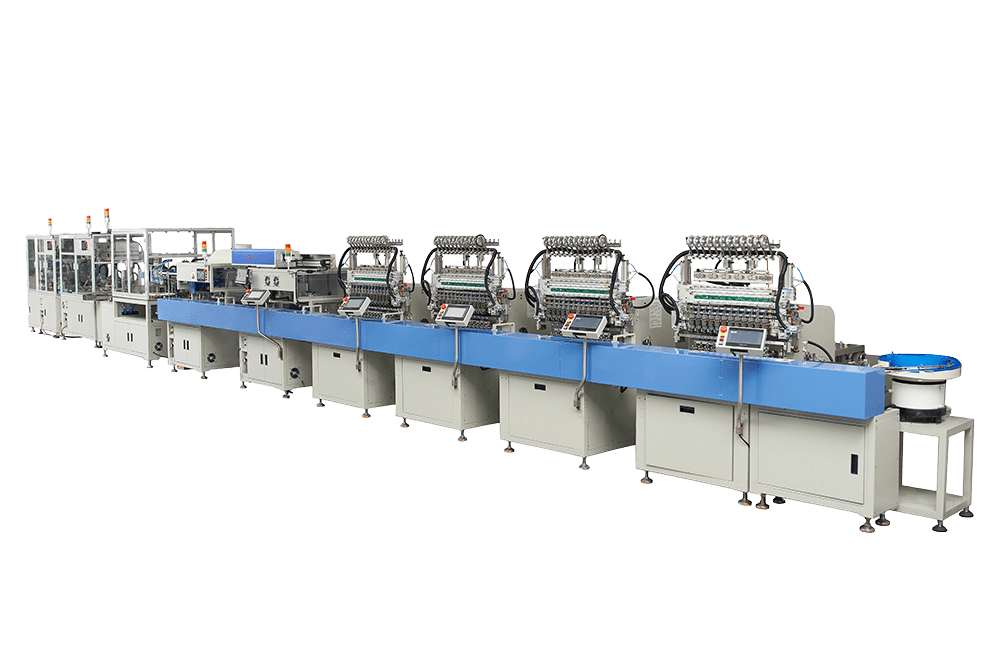

Overview of the Fully Automatic Production Line for Ferrite SMPS Transformers

A Fully Automatic Production Line for Ferrite SMPS Transformers is a modular, sequential automation system where each process station is connected in series. Every machine performs a specific task and automatically transfers the transformer to the next station without manual intervention.

The standard production flow includes:

- Automatic bobbin feeding

- Automatic bobbin loading into winding machines

- Sequential multi‑winding stations with insulation taping

- Automatic transfer to soldering station

- Flux dipping and solder dipping

- Automatic core feeding and assembly

- Optional glue dispensing

- Automatic core taping

- Inline electrical testing

- Optional hi‑pot and CCD inspection

- Automatic unloading into trays

Each section of the line is synchronized to maintain consistent cycle time and optimal throughput. The modular design allows customization based on transformer type, number of windings, and required testing level.

Machine Working Video

Fully Automatic Production Machine Line for Ferrite SMPS Transformers

Complete Line Architecture & Workflow Design

A fully automatic production line for ferrite SMPS transformers is designed as a closed-loop, sequential workflow system, where each process is logically connected to the next. The objective is simple but critical: zero manual handling, zero process interruption, and zero quality variation.

The line architecture is modular in nature, meaning individual machines are arranged in series and synchronized through conveyors, robotic transfer systems, or linear indexing mechanisms. Each station performs a predefined task and automatically hands over the transformer bobbin or coil to the next station.

Key principles of the line architecture include:

- Single-direction material flow (no backtracking)

- Fixed cycle time synchronization between machines

- Automatic transfer and positioning accuracy

- Expandability for future process additions

This architecture ensures smooth production flow, predictable output, and easy scalability.

Automatic Bobbin Feeding System

The production line begins with the automatic bobbin feeding system, which eliminates manual loading and orientation errors. Bobbins are fed in bulk and automatically aligned before entering the winding section.

1. Bobbin Feeding Mechanism : Depending on bobbin size and shape, the system may include:

- Vibratory bowl feeder

- Step feeder or magazine feeder

- Linear feeder with orientation control

Each bobbin is checked for correct orientation and dimensions before being released to the loading station. Incorrect or damaged bobbins can be automatically rejected to prevent downstream issues.

2. Advantages of Automatic Bobbin Feeding

- Eliminates operator fatigue and loading errors

- Ensures consistent orientation for winding accuracy

- Supports continuous, unattended production

- Improves overall line efficiency

Once correctly oriented, the bobbin is transferred automatically to the first winding machine.

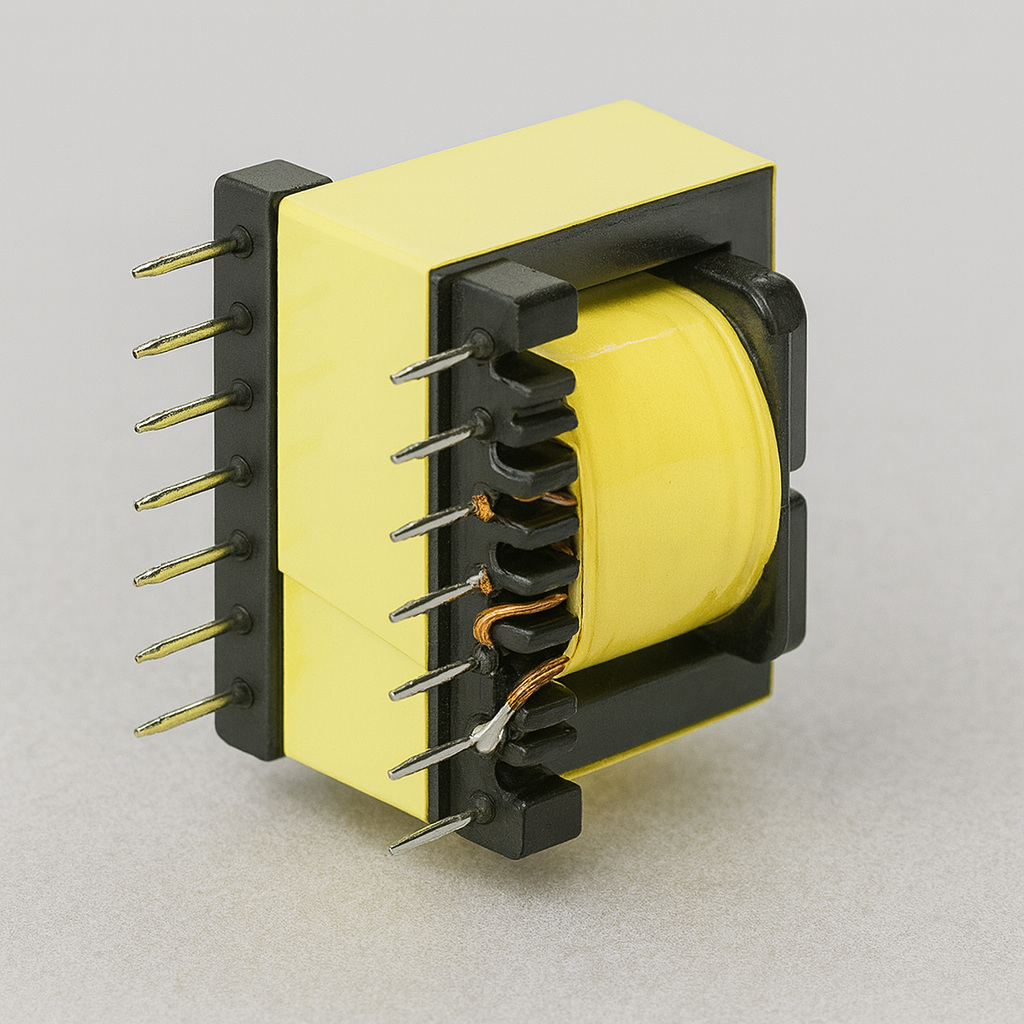

Automatic Bobbin Loading into the First Winding Machine

After feeding, the bobbin is automatically picked and positioned into the winding fixture of the first winding machine. Precision loading is critical, as even minor misalignment can affect winding accuracy and insulation placement.

The loading system typically includes:

- Pneumatic or servo-driven pick-and-place unit

- Precision locating fixtures

- Presence and position sensors

Once the bobbin is securely clamped, the machine signals readiness to begin winding operations.

This automatic loading mechanism ensures:

- Accurate bobbin positioning every cycle

- No human dependency

- Repeatable and reliable machine operation

Sequential Multi-Winding Automation Concept

One of the most powerful features of a fully automatic SMPS transformer production line is the sequential multi-winding concept. Instead of performing all windings on a single station, the production line uses multiple winding machines connected in series, each dedicated to a specific winding.

This approach offers several advantages:

- Optimized cycle time per station

- Simplified machine programming

- Better insulation control between windings

- Easier maintenance and troubleshooting

Each winding machine performs one winding operation and then automatically transfers the coil to the next station.

Automatic Transfer to Soldering Station

Upon completion of all winding operations, the finished coil is transferred automatically to the soldering station. This transfer is synchronized to avoid bottlenecks and ensure continuous flow.

The transfer mechanism may include:

- Conveyor systems

- Robotic arms

- Linear transfer units

The coil is precisely positioned for soldering to ensure reliable electrical connections.

Flux Dipping and Dip Soldering System

After completion of all winding operations, the transformer coil enters the automatic soldering section, which is one of the most critical quality-determining stages in SMPS transformer manufacturing. In a fully automatic production line, soldering is performed in a controlled, repeatable, and operator-independent manner.

1. Automatic Flux Dipping : Before soldering, the coil terminals are passed through an automatic flux dipping unit. This system ensures:

- Uniform flux application on all terminals

- Improved solder wetting and joint reliability

- Elimination of manual brushing or spraying

Flux quantity, dipping depth, and dwell time are precisely controlled to avoid excess residue and ensure clean solder joints.

2. Dip Soldering Process : Following flux application, the coil is transferred to the dip soldering station. Key features include:

- Temperature-controlled solder pot

- Consistent immersion depth

- Stable dwell time for each cycle

- Oxidation control for solder quality

This process guarantees strong electrical connections with minimal variation between units.

Automatic Ferrite Core Feeding System

The next stage of the production line focuses on ferrite core handling. Manual core feeding often leads to breakage, misalignment, and inconsistent assembly quality. Fully automatic lines eliminate these risks through dedicated core feeding systems.

Ferrite cores are supplied via:

- Magazine feeders

- Tray-based feeding systems

- Robotic pick-and-place units

Each core half is oriented correctly before assembly to ensure precise magnetic alignment.

Automatic Core Assembly Station

In the automatic core assembly station, the ferrite core halves are accurately positioned and assembled onto the transformer coil.

Key advantages of automatic core assembly include:

- Consistent air gap control (if required)

- Accurate core positioning

- Reduced core damage and breakage

Servo-controlled pressing ensures uniform mechanical pressure, which directly impacts transformer performance and noise characteristics.

Automatic Core Taping Machine

After core assembly (and glue dispensing, if used), the transformer is transferred to an automatic core taping machine.

The taping system provides:

- Uniform tape tension

- Consistent overlap and coverage

- Improved insulation and mechanical stability

Automatic core taping ensures long-term reliability, especially for transformers used in high-vibration or high-temperature environments.

Automatic Transfer to Inline Testing Unit

Once mechanical assembly is completed, the transformer is automatically transferred to the inline testing section. This integration ensures that every transformer is electrically verified before unloading.

Automated transfer eliminates handling damage and maintains continuous production flow. The testing station performs comprehensive electrical checks to ensure each transformer meets design and safety specifications.

Typical inline tests include:

- Inductance measurement

- Leakage inductance

- DC resistance (DCR)

- Turns ratio verification

- Winding polarity confirmation

Optional Hi-Pot Testing & CCD Vision Inspection

For safety-critical applications, an optional hi-pot testing unit can be integrated. This test verifies insulation strength and ensures compliance with international safety standards.

CCD vision systems can be added to inspect:

- Core & Winding appearance

- Terminal alignment

- Solder joint quality

This adds an extra layer of quality assurance without slowing production.

Automatic Unloading into Trays or Safe Storage

After successful testing, the transformer is automatically unloaded into trays or designated storage areas. This final step ensures:

- Safe handling of finished products

- Organized batch management

- Readiness for packing or further assembly

The entire process from bobbin feeding to finished transformer unloading is completed without manual intervention, delivering unmatched efficiency and consistency.

Key Technical Features of the Fully Automatic Production Line

A fully automatic production line for ferrite SMPS transformers is built around precision, stability, and long-term industrial reliability. Some of the key technical features include:

- Fully synchronized multi-machine architecture

- Servo-driven winding control for accurate turns and tension

- Automatic insulation tape cutting and placement

- Zero manual handling between processes

- PLC + HMI based centralized control system

- Recipe-based product changeover

- Inline testing with data logging capability

- Modular design for future expansion

These features ensure that the production line delivers consistent quality regardless of shift changes, operator skill, or production volume.

Supported Ferrite Core Types and Transformer Configurations

The fully automatic production line can be customized to support a wide range of ferrite core shapes and transformer designs, including:

- EE / EER series ferrite transformers

- EFD series for compact SMPS designs

- ETD cores for higher power applications

- PQ cores for high-efficiency power supplies

- RM cores for precision electronics

The line can be configured for transformers with:

- Single or multiple secondary windings

- Auxiliary windings

- Different wire gauges and insulation schemes

- Custom pin layouts and termination styles

This flexibility makes the line suitable for both standard and custom transformer manufacturing.

Industries and Manufacturers Who Benefit from This Line

A fully automatic ferrite SMPS transformer production line is ideal for:

- SMPS power supply manufacturers

- Mobile charger and adapter manufacturers

- LED driver manufacturers

- Solar inverter and UPS manufacturers

- EV charger and power module manufacturers

- Industrial automation and control panel OEMs

Manufacturers targeting high-volume, export-quality production gain the maximum benefit from such automation.

Advantages of Fully Automatic Ferrite SMPS Transformer Production

Key advantages include:

- High and predictable production output

- Consistent electrical and mechanical quality

- Significant reduction in labor dependency

- Lower rejection and rework rates

- Improved safety and workplace cleanliness

- Easy scalability for future demand

Automation not only improves productivity but also strengthens brand reputation by ensuring uniform product quality.

Production Capacity and Scalability

Production capacity depends on transformer complexity, number of windings, and testing requirements. However, a typical fully automatic line can achieve:

- Continuous multi-shift operation

- Stable cycle time per unit

- High daily and monthly output

The modular architecture allows manufacturers to add:

- Additional winding stations

- Extra testing modules

- Automation for downstream packaging

as production demand grows.

ROI and Payback – A Practical Perspective

Return on investment is one of the strongest justifications for adopting a fully automatic production line.

Key ROI drivers include:

- Reduction in manual labor cost

- Higher output per shift

- Lower rejection and warranty cost

- Consistent quality enabling premium customers

In most industrial scenarios, manufacturers achieve payback within a reasonable period once production volumes stabilize, making automation a strategic long-term investment.

How to Choose the Right Automation Partner or Manufacturer

Selecting the right vendor is as important as selecting the right machine.

Key evaluation points include:

- Experience in transformer automation

- Ability to customize machines based on samples

- Quality of after-sales support and service

- Availability of spare parts

- Proven installations and references

A reliable partner focuses not only on selling machines but also on ensuring long-term production success.

Why Choose Deptronics Technologies

Deptronics Technologies is a trusted automation partner for ferrite SMPS transformer manufacturing in India.

Key strengths include:

- Strong expertise in transformer winding and automation

- Direct association with advanced OEM manufacturers

- Sample-based machine evaluation and programming

- Transparent commercial structure

- Installation, training, and service support in India

Deptronics focuses on delivering complete, working production solutions rather than standalone machines.

Installation, Training, and After-Sales Support

Successful automation depends heavily on post-installation support.

Deptronics Technologies provides:

- Pre-dispatch inspection and customer validation

- On-site installation and commissioning

- Operator and maintenance training

- Long-term service and technical support

This ensures smooth transition from manual or semi-automatic production to full automation.

Frequently Asked Questions (FAQs)

Q1. Can the line be customized for different transformer models?

Yes, the line is modular and can be configured based on transformer design and production volume, but we recommend to use only for one single product to achieve better efficiency & long life of machine.

Q2. Is hi-pot testing mandatory?

Hi-pot testing is optional and recommended for safety-critical applications.

Q3. Can future automation modules be added later?

Yes, the line is designed for future scalability.

Q4. Do you provide local support in India?

Yes, Deptronics provides complete installation and service support in India.

Conclusion

A fully automatic production line for ferrite SMPS transformers represents the future of transformer manufacturing. By integrating winding, soldering, core assembly, taping, and testing into a single automated workflow, manufacturers achieve unmatched efficiency, quality consistency, and scalability.

For companies aiming to compete in high-volume, high-quality markets, investing in such automation is no longer optional—it is essential.

Contact Us

For machine inquiries, pricing, or customization options, contact us today!

DEPTRONICS TECHNOLOGIES

📌 Contact Person: Deepanshu Saxena

📞 WhatsApp/ Mobile: +91-8800622761

🌐 Website: https://coilwinder.in/

📧 Email: [email protected]

For mass production of relay coils, check our “Automatic Production Line for Mass Manufacturing of Relay Coils”

Reviews

There are no reviews yet.