Multi-spindle coil winding machines are usually used in transformer, relay, solenoid, high frequency chock coils, inductors winding.

We are leading supplier and dealer of Programmable coil winding machines providing full service and support after-sales.

We offered high features & low cost machines with its simple design and optimum winding speeds.

Designed and developed with sophisticated manufacturing technology the robust quality machine is accessible with standard accessories at a market leading price.

We offered different types of models in our multi-spindle winding section.

Based on customer’s requirements and production target, we can offer 12, 16, 20 & 24 spindle coil winding machines.

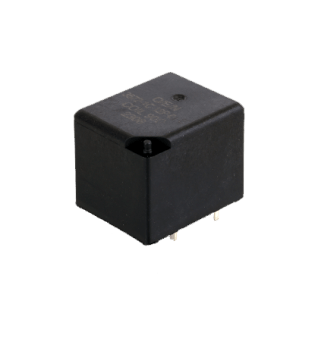

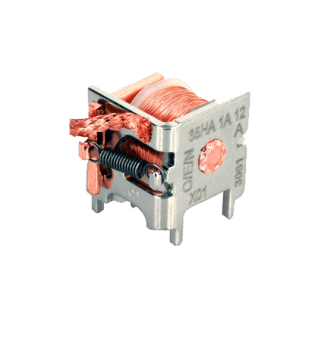

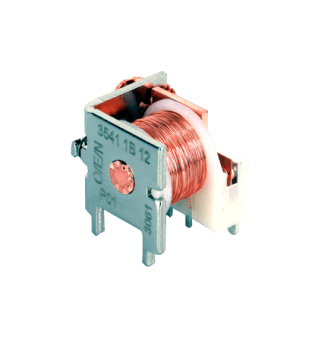

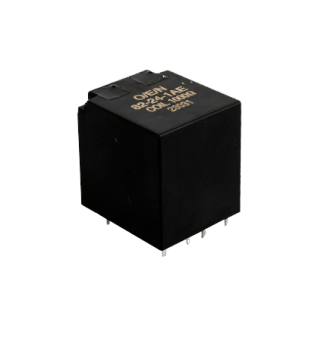

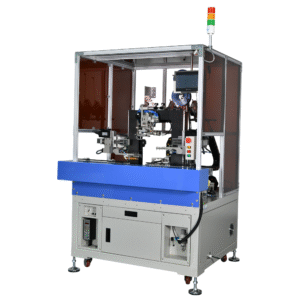

Automotive PCB Micro High Current Relay Coil Winding Machine

Machine Specifications

| Model | NMT-8008 | NMT-8012 | NMT-8016 |

| Number of Spindle | 8 | 12 | 16 |

| XYZ Axis Control System | CNC Precise software control | CNC Precise software control | CNC Precise software control |

| Data Storage | RAM+ FLASH | RAM+ FLASH | RAM+ FLASH |

| Tensioner | Magnetic Or Servo Tensioner | Magnetic Or Servo Tensioner | Magnetic Or Servo Tensioner |

| Pitch between spindles | 45 mm | 45 mm | 45 mm |

| Max. of bobbin diagonal | 40 mm | 35/60 mm | 35 mm |

| Servo Motor | Spindle : 1500W Option : X:200 Y:200 Z:400 | Spindle : 1500W Option : X:200 Y:200 Z:400 | Spindle : 1500W Option : X:200 Y:200 Z:400 |

| Winding Direction | CW/CCW | CW/CCW | CW/CCW |

| Spindle stop accuracy | +/- 0.1 degree | +/- 0.1 degree | +/- 0.1 degree |

| Wire Range (mm) | 0.02~0.4 | 0.02~0.4 | 0.02~0.4 |

| X Axis Nozzle moving forward & backward distance | 110 mm | 110 mm | 110 mm |

| Y Axis Nozzle moving left & right distance | 150 mm | 150 mm | 150 mm |

| Z Axis Nozzle moving up & down distance | 70 mm | 70 mm | 70 mm |

| XYZ axis speed | 200 mm/sec. | 200 mm/sec. | 200 mm/sec. |

| XYZ axis moving precision | 0.01 mm | 0.01 mm | 0.01 mm |

| Wire Anchoring Angle | 0/ 90 degree | 0/ 90 degree | 0/ 90 degree |

| Power | AC 220V, 50Hz | AC 220V, 50Hz | AC 220V, 50Hz |

| Power Consumption | 3000W | 3000W | 3500W |

| Air Pressure | 4~6 kgf/cm2 | 4~6 kgf/cm2 | 4~6 kgf/cm2 |

| Machine Dimension (LxWxH) | 1350 x 1250 x 1400 | 1350 x 1250 x 1400 | 1350 x 1250 x 1400 |

| Space required for machine | L2550 x W2900x H2000 mm | L2550 x W2900x H2000 mm | L2550 x W2900x H2000 mm |

| Machine Weight | 750 kg. | 800 kg. | 850 kg. |

| Optional Functions | Fully auto loading- unloading, auto taping, auto wire clip, waste wire discharge | Fully auto loading- unloading, auto taping, auto wire clip, waste wire discharge | Fully auto loading- unloading, auto taping, auto wire clip, waste wire discharge |

| Optional Devices | Wire Twisting, Niper/ pneumatic cutter, servo tension meter, Copper enamel remover | Wire Twisting, Niper/ pneumatic cutter, servo tension meter, Copper enamel remover | Wire Twisting, Niper/ pneumatic cutter, servo tension meter, Copper enamel remover |

More details, please contact freely :

DEPTRONICS TECHNOLOGIES

Contact : Deepanshu Saxena

Mobile : +91-8800622761

WhatsApp : https://wa.me/918800622761

Email : [email protected]

Reviews

There are no reviews yet.